Positioning structure for PCB and upper insulation support

A technology of insulating support and positioning structure, which is applied to the shape/style/structure, structural connection, casing/cover/support of winding conductors, etc., can solve problems such as easy occurrence of defective products and difficult automation, and improve production efficiency. , the effect of ensuring accuracy and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

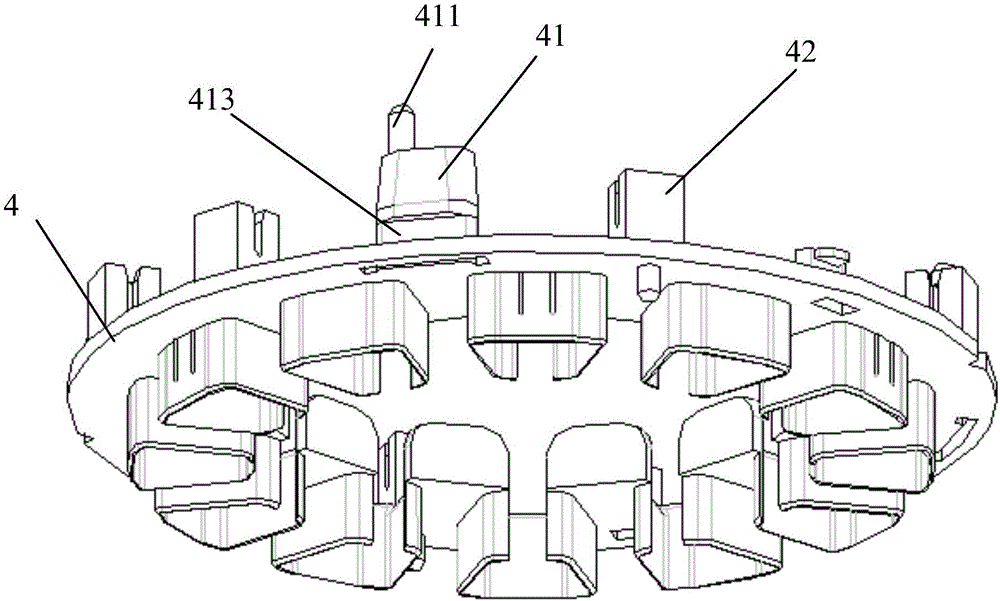

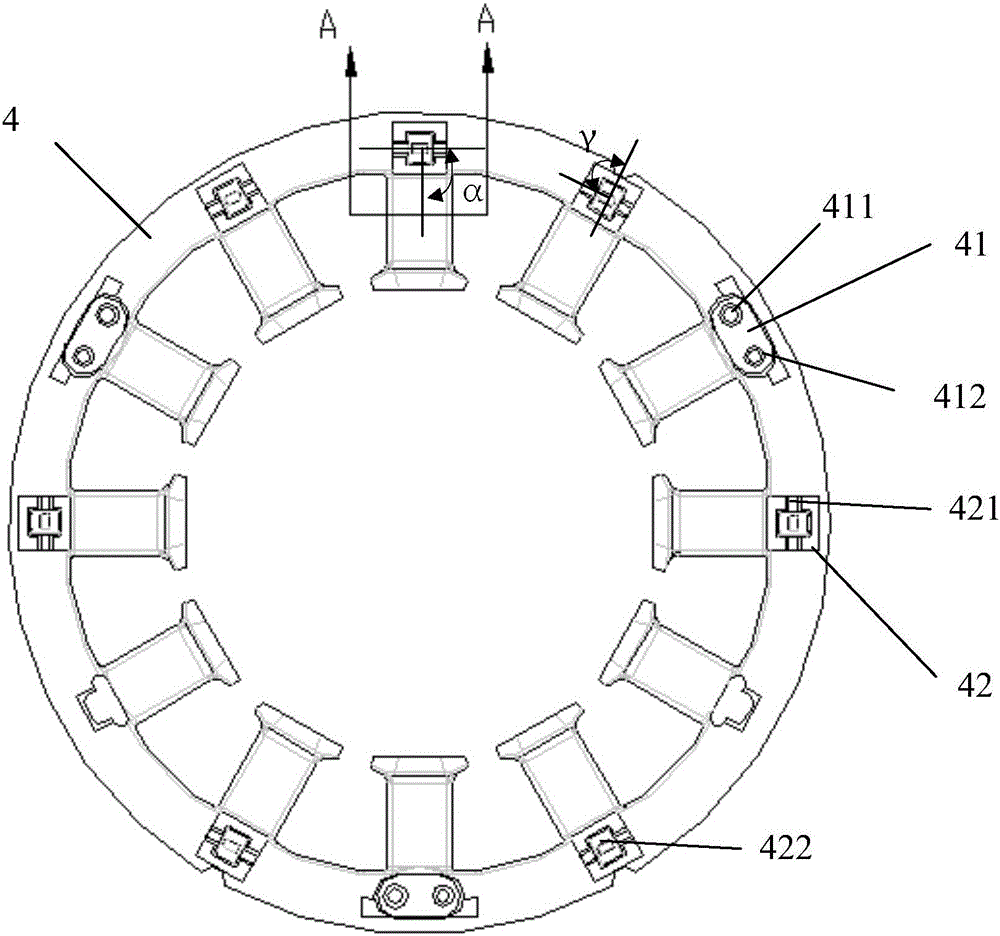

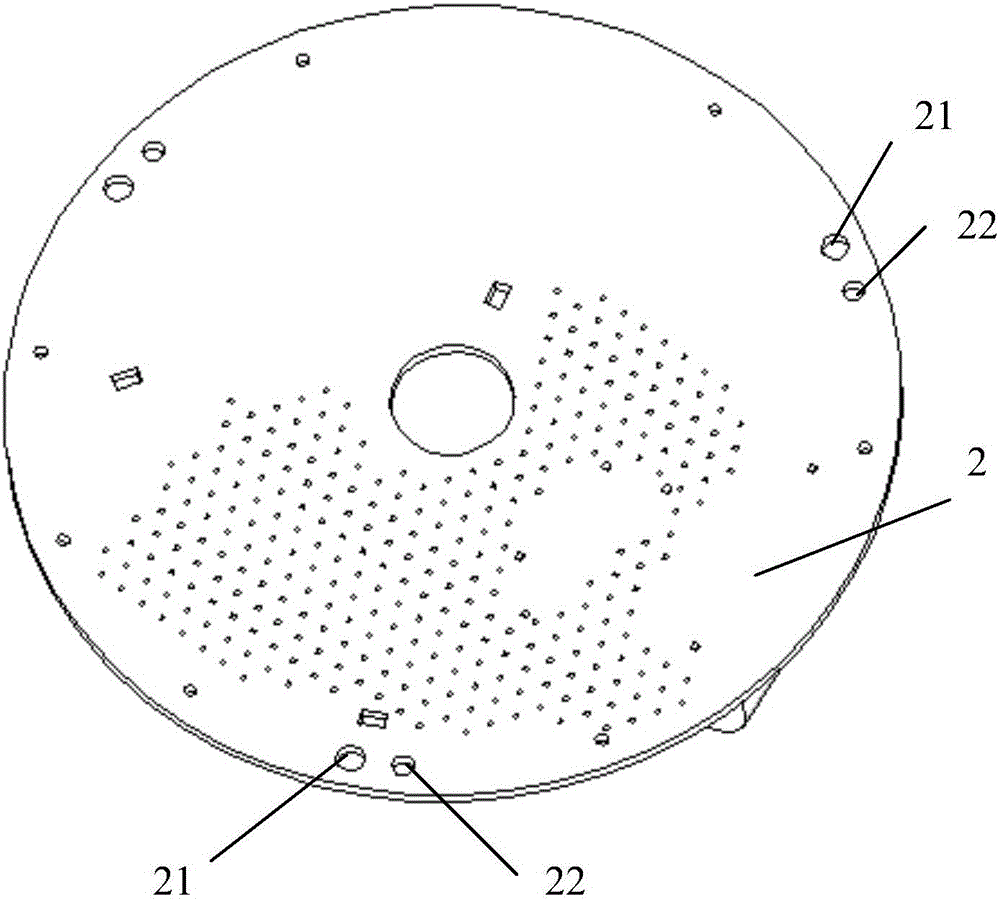

[0038] The embodiment of the present invention provides a positioning structure for a PCB board and an upper insulating bracket, which is suitable for brushless motors, see figure 1 , the positioning structure includes: an upper insulating bracket 4 .

[0039] The upper surface of the upper insulating support 4 is evenly provided with a plurality of positioning platforms 41 along the circumferential direction, and the top surface of the positioning platforms 41 is higher than the top surface of the terminal fixing seat 42 arranged on the upper surface of the upper insulating support 4. h, h is greater than zero, The terminal fixing seat 42 is used for inserting an insulation displacement connection (Insulation Displacement Connection, “IDC” for short) terminal (not marked in the drawings).

[0040] The top surface of each positioning platform 41 is provided with a guide positioning column 411, and one end where the guiding positioning column 411 cooperates with the PCB board 2...

Embodiment 2

[0051] The embodiment of the present invention provides a positioning structure for a PCB board and an upper insulating bracket, which is suitable for brushless motors, see Figure 4 , the positioning structure includes: an upper insulating bracket 4 .

[0052] The upper surface of the upper insulating support 4 is evenly provided with a plurality of positioning platforms 41 along the circumferential direction, and the top surface of the positioning platforms 41 is higher than the top surface of the terminal fixing seat 42 arranged on the upper surface of the upper insulating support 4. h, h is greater than zero, The terminal fixing base 42 is used for inserting IDC terminals.

[0053] The top surface of each positioning platform 41 is provided with a guide positioning column 411, and one end where the guiding positioning column 411 cooperates with the PCB board 2 is a tapered structure; There is a wire slot 413 for limiting wires.

[0054] see Figure 5 , the top surface o...

Embodiment 3

[0081] An embodiment of the present invention provides a positioning structure for a PCB board and an upper insulating bracket. In practical applications, the upper insulating bracket in the positioning structure can form a stator with an insulating bracket with other structures. See Figure 8 , the stator with an insulating support includes: a stator core 5, an upper insulating support 4 and a lower insulating support 7 are respectively inserted on the upper and lower end surfaces of the stator iron core 5, and a plurality of terminals are arranged on the upper surface of the upper insulating support 4 The fixing seat 42 and a plurality of wire passing seats 46 are provided on the lower surface of the lower insulating support 7 with a plurality of wire passing seats 46 .

[0082] see Figure 9 and Figure 10 , the upper slot insulation 43 on the upper insulating bracket 4, the winding teeth (not marked in the drawings) on the stator core 5 and the lower slot insulation 73 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com