Boron type flame retardant directional shaving board and preparation method thereof

A technology of oriented strand board and wood shavings, used in flat products, manufacturing tools, other household appliances, etc., to achieve the effects of high internal bonding strength, improved internal bonding strength and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

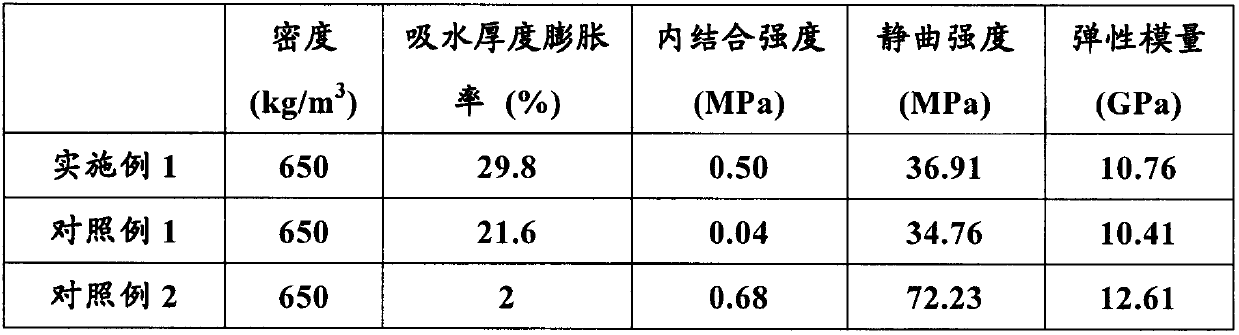

Examples

Embodiment 1

[0031] 1. Dry

[0032] The cut wood shavings are placed in a drying box to dry, so that the moisture content of the wood shavings is 3 to 5%;

[0033] 2. Spray flame retardant

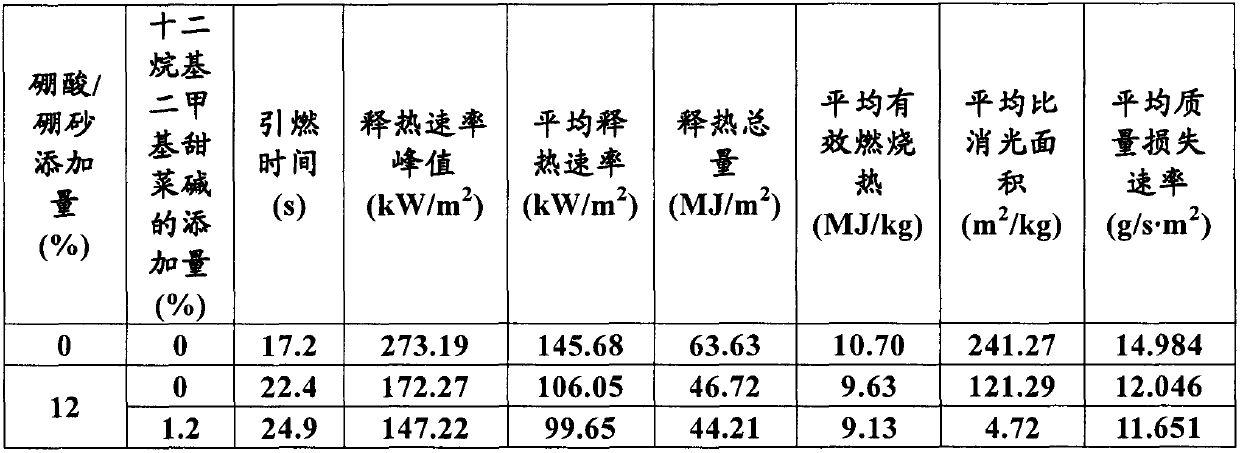

[0034] Spray the compounded boric acid / boric acid and dodecyl dimethyl betaine into the glue mixer, and stir evenly to make flame-retardant wood shavings, wherein the weight of added boric acid, borax, dodecane The ratio of the weight of dimethyl betaine to the weight (dry) of wood shavings is 6:6:1.2:100;

[0035] 3. Dry again

[0036] The wood shavings applied with the flame retardant are placed in a drying box to dry, so that the moisture content of the wood shavings is 3 to 5%;

[0037] 4. Sizing

[0038] Firstly add the dried wood shavings into the glue mixer again, then spray the phenolic resin adhesive, and stir evenly to obtain sizing wood shavings, wherein the ratio of the total weight (dry) of the phenolic resin adhesive to the wood shavings is 9:100 ;

[0039] 5. Paving

[0040] Evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com