Production method of epoxy resin-based thermal-conductive insulating paste

An epoxy resin, heat conduction and insulation technology, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems that the thermal conductivity and insulation performance cannot be further improved, the dispersion of fillers is uneven, and the thermal conductivity is not good. Achieve the effect of improving thermal conductivity, improving thermal conductivity, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

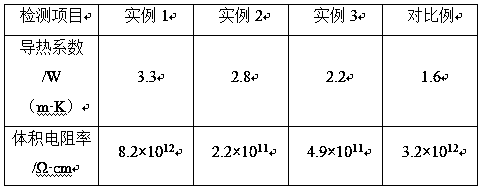

Examples

example 1

[0026] Mix aluminum nitride and dopamine solution with a mass fraction of 12% at a mass ratio of 1:12, soak at room temperature for 3 hours, and filter to obtain pretreated aluminum nitride. Pretreated aluminum nitride and silane coupling agent KH -550 was mixed in a beaker at a mass ratio of 3:1, and ethanol 10 times the mass of pretreated aluminum nitride was added to the beaker, and stirred and mixed for 6 hours at a temperature of 40°C and a rotational speed of 500r / min to obtain Pretreat the aluminum nitride dispersion; mix the graphene oxide dispersion and 4,4'-diaminodiphenyl ether in a three-necked flask at a mass ratio of 220:1, and feed it into the three-necked flask at a rate of 35mL / min Nitrogen, at a temperature of 35°C and a rotational speed of 350r / min, stir and react for 3 hours, then filter to obtain a functionalized graphene oxide blank, and wash the functionalized graphene oxide blank with N-methylpyrrolidone for 8 times , and then washed with ethanol and wa...

example 2

[0028] The graphene oxide dispersion and 4,4'-diaminodiphenyl ether were mixed in a three-necked flask at a mass ratio of 220:1, and nitrogen gas was passed into the three-necked flask at a rate of 35mL / min at a temperature of 35°C. Under the condition of rotating speed of 350r / min, after stirring and reacting for 3h, filter to obtain the functionalized graphene oxide blank, wash the functionalized graphene oxide blank with N-methylpyrrolidone for 8 times, and then wash with ethanol and water respectively 6 times, dry the washed functionalized graphene oxide blank at a temperature of 60°C for 2 hours to obtain functionalized graphene oxide; mix functionalized graphene oxide and water in a flask at a mass ratio of 1:150 , and N, N-dimethylformamide, which is 80 times the mass of functionalized graphene oxide, was added to the flask, and the functionalized graphite oxide was obtained after stirring and mixing for 50 minutes at a temperature of 50 ° C and a rotational speed of 350...

example 3

[0030] Mix aluminum nitride and dopamine solution with a mass fraction of 12% at a mass ratio of 1:12, soak at room temperature for 3 hours, and filter to obtain pretreated aluminum nitride. Pretreated aluminum nitride and silane coupling agent KH -550 was mixed in a beaker at a mass ratio of 3:1, and ethanol 10 times the mass of pretreated aluminum nitride was added to the beaker, and stirred and mixed for 6 hours at a temperature of 40°C and a rotational speed of 500r / min to obtain Pretreat the aluminum nitride dispersion; mix the graphene oxide dispersion and 4,4'-diaminodiphenyl ether in a three-necked flask at a mass ratio of 220:1, and feed it into the three-necked flask at a rate of 35mL / min Nitrogen, at a temperature of 35°C and a rotational speed of 350r / min, stir and react for 3 hours, then filter to obtain a functionalized graphene oxide blank, and wash the functionalized graphene oxide blank with N-methylpyrrolidone for 8 times , and then washed with ethanol and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com