Packaging structure and packaging method of micro-electromechanical system (MEMS) sensor

A packaging structure and sensor technology, which is applied to the coupling of electric solid devices, semiconductor devices, and optical waveguides, can solve problems such as large differences in thermal expansion coefficients, MEMS chip deformation of MEMS sensor chips, and failure of MEMS sensor chip devices. Small-impact, overall performance-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solution of the present application will be described in further detail below in conjunction with the accompanying drawings.

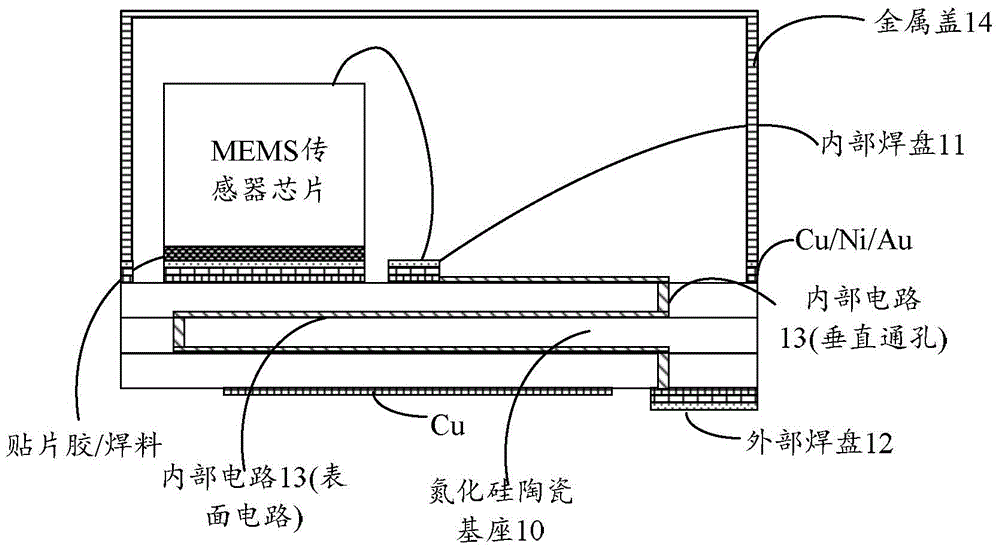

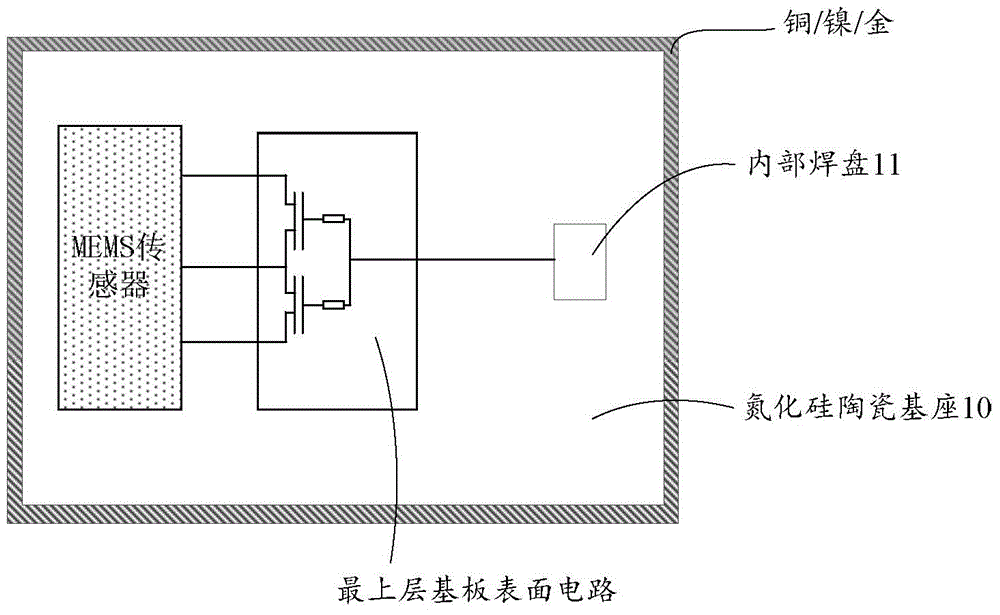

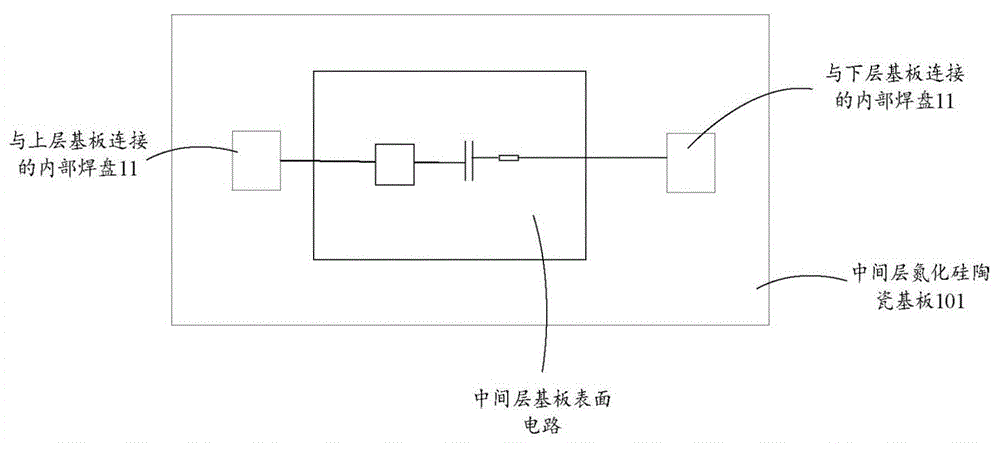

[0053] figure 1 is a cross-sectional view of a package structure of a MEMS sensor according to an embodiment of the present application, figure 2 It is a schematic top view of the package structure of the MEMS sensor according to an embodiment of the present application after the metal cover is removed. The packaging structure of the MEMS sensor of the embodiment of the present application is used to package the MEMS sensor chip made of silicon material. The packaging structure includes: a silicon nitride ceramic base 10, an internal pad 11, an external pad 12, an internal circuit 13, a metal Cover 14.

[0054] Wherein, the silicon nitride ceramic base 10 is used to fix the MEMS sensor chip, preferably fixed at the center position of the silicon nitride ceramic base 10; the silicon nitride ceramic base 10 may include at least on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com