Technique for producing wood bundle board by using straws

A wood bundle board and straw technology, which is applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of unfavorable large-scale industrial production, high cost of boards, and low strength of boards, so as to facilitate paving The effect of forming blanks, improving labor productivity, and improving nail holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

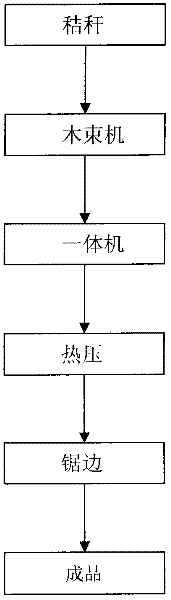

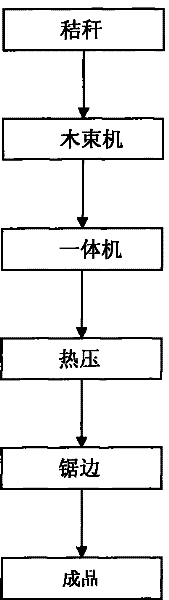

Image

Examples

Embodiment 1

[0017] First, one of sunflower stalks, flue-cured tobacco stalks, corn stalks, sorghum stalks, and rapeseed stalks is sent into the wood beam processing machine, and 20-30 pieces are sent each time, and the wood beam processing machine completes flattening, cutting, Cutting into sections, winnowing and dedusting, and finally get 5mm wide and 70mm long wood bundle strips without skin, pith and impurities, and then send the wood bundle strips into the all-in-one machine, which will be dried by the all-in-one machine to make the water content ≤ 6% , and then enter the glue mixing section. The glue can be urea-formaldehyde glue. The strands are laid flat according to the thickness requirements, and then three sets of flattening rollers corresponding to each of the three layers of vibrating screens are used for initial pressing, and then the three layers of initially pressed slabs are pressed together in the slab combining section composed of 6 sets of rollers. Together, a complete...

Embodiment 2

[0019] One of the five kinds of straw is processed into 5mm wide and 70mm long wooden beam strips, which are dried, glue mixed, paved and billeted by the integrated machine, and then sent to the hot press machine. The glue material can be phenolic glue. The amount of glue is 8% of the net weight of the wood beam strips, and the wood beam strips can be selected from any of the five kinds of straws. The other process conditions are the same as in Example 1, and qualified wood beam boards can also be produced.

Embodiment 3

[0021] After the whole straw is processed into wooden beams, it is sent to the all-in-one machine, which completes drying, glue mixing, and paving. After forming the billet, it is sent to the hot press machine. It is 5% of the net weight of wood beam strips, and other process conditions are the same as embodiment 1, and qualified wood beam boards can be produced equally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com