Preparation method of soybean-protein-adhesive-based medium-density fiberboard

A soybean protein and adhesive technology, applied in the preparation of animal glue or gelatin, protein adhesive, adhesive and other directions, can solve the problems of high formaldehyde emission, high cost, low strength, etc., and achieves simple process and uniform density. , the effect of conducive to industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

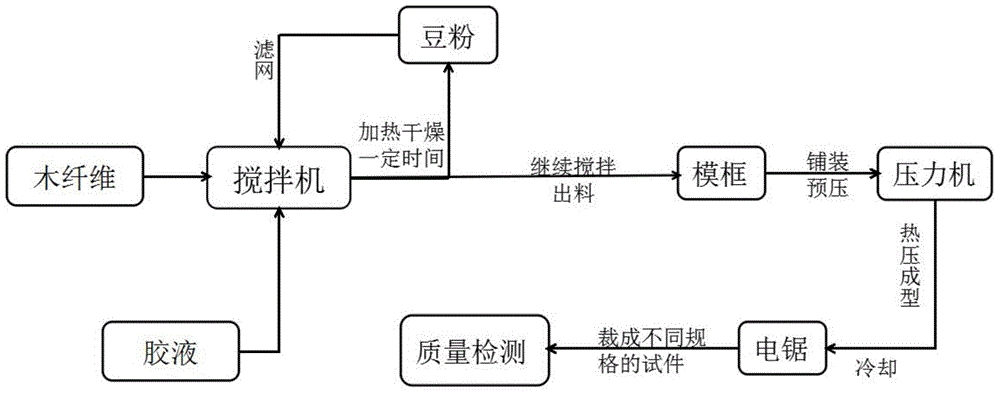

Method used

Image

Examples

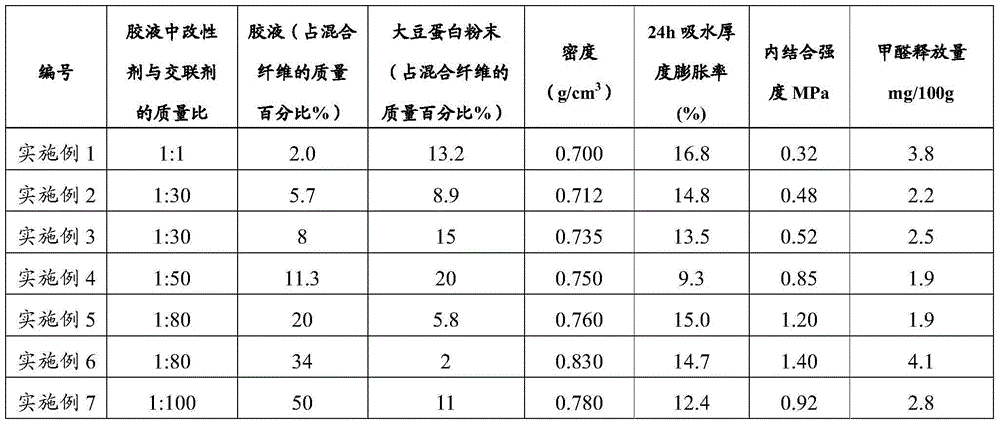

Embodiment 1

[0029] Put the mixed fiber into the blender and stir, and at the same time, spray the glue prepared by blending the modifier boric acid and the crosslinking agent polyamide polyamine epichlorohydrin according to the mass ratio of 1:1 into the blender. 2% of the fiber mass, continue to stir and heat and dry at 80°C for 2 minutes, then add soybean protein powder accounting for 13.2% of the mixed fiber mass, continue to stir evenly, and then discharge. Spread the mixed material evenly into the mold frame of the required specification, give a pressure of 2MPa, and pre-press it into a slab. Then hot-press the pre-formed slab with a flat vulcanizer at 100°C. The hot-pressing process is: first increase the pressure to 10MPa within 10s, and keep the pressure for 20s; reduce the pressure to 4.0MPa, and keep the pressure for 20-250s; 50s Internally boost the pressure to 4.0MPa, hold the pressure for 50s; reduce the pressure to 3.0Mpa, hold the pressure for 100s, and the hot pressing end...

Embodiment 2

[0031] The operation steps are the same as in Example 1, wherein the mass ratio of the modifier to the crosslinking agent becomes 1:30, the mass percentage of the soybean protein adhesive solution in the mixed fiber becomes 5.7%, and the soybean protein powder accounts for 5.7% of the mixed fiber. The mass percentage is changed to 8.9%, the heating and drying temperature is changed to 60°C, the drying time is changed to 4min, the pre-pressing pressure is changed to 1MPa, the hot-pressing temperature is changed to 150°C, and the hot-pressing process is as follows: first, the pressure is raised to 8.0MPa within 20s , keep the pressure for 15s; reduce the pressure to 3.0MPa, keep the pressure for 20s; increase the pressure to 3.0MPa within 50s, keep the pressure for 80s; step down to 2.0Mpa, keep the pressure for 80s, and the hot pressing ends; after the board is out, cooled, sawed Edge, sanding and other steps to produce medium density fiberboard. Finally, the quality of the pre...

Embodiment 3

[0033] The operation steps are the same as in Example 1, wherein the mass ratio of the modifier to the crosslinking agent is changed to 1:30, the mass percentage of the soybean protein adhesive solution in the mixed fiber is changed to 8%, and the soybean protein powder accounts for the mixed fiber. The mass percentage is changed to 15%, the heating and drying temperature is changed to 60°C, the drying time is changed to 4min, the pre-pressing pressure is changed to 1MPa, the hot-pressing temperature is changed to 200°C, and the hot-pressing process is as follows: first boost the pressure to 8.0MPa within 20s , keep the pressure for 15s; reduce the pressure to 3.0MPa, keep the pressure for 20s; increase the pressure to 3.0MPa within 50s, keep the pressure for 80s; step down to 2.0Mpa, keep the pressure for 80s, and the hot pressing ends; after the board is out, cooled, sawed Edge, sanding and other steps to produce medium density fiberboard. Finally, the quality of the prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com