Asphalt concrete and preparation process thereof

A kind of asphalt concrete and preparation technology, which is applied in the field of concrete production and manufacturing, can solve the problems of easy cracking and low internal bonding strength, and achieve the effects of not being easy to break, saving land and money, and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: a kind of asphalt concrete, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

[0054] Step 1, stirring and drying the basalt masterbatch corresponding to the weight part in the drying barrel, the temperature is controlled at 120°C, the time is 150min, and the stirring speed is 1500rpm, to obtain the dried basalt masterbatch;

[0055] Step 2: Sieve the dried basalt masterbatch to obtain basalt particles with particle sizes of 3mm, 5mm, and 18mm respectively, and mix them evenly according to the weight ratio of 2:3:5, and add mineral powder and iron tailings The master batch is stirred evenly together to obtain the basalt ingredient;

[0056] Step 3, put basalt ingredients, talc powder, RA anti-rutting agent and silicon carbide into the mixing tank for dry mixing, the time is 10s, and the stirring speed is 1500rpm;

[0057] Step 4: Heat the asphalt in corresponding parts by weight to...

Embodiment 2-8

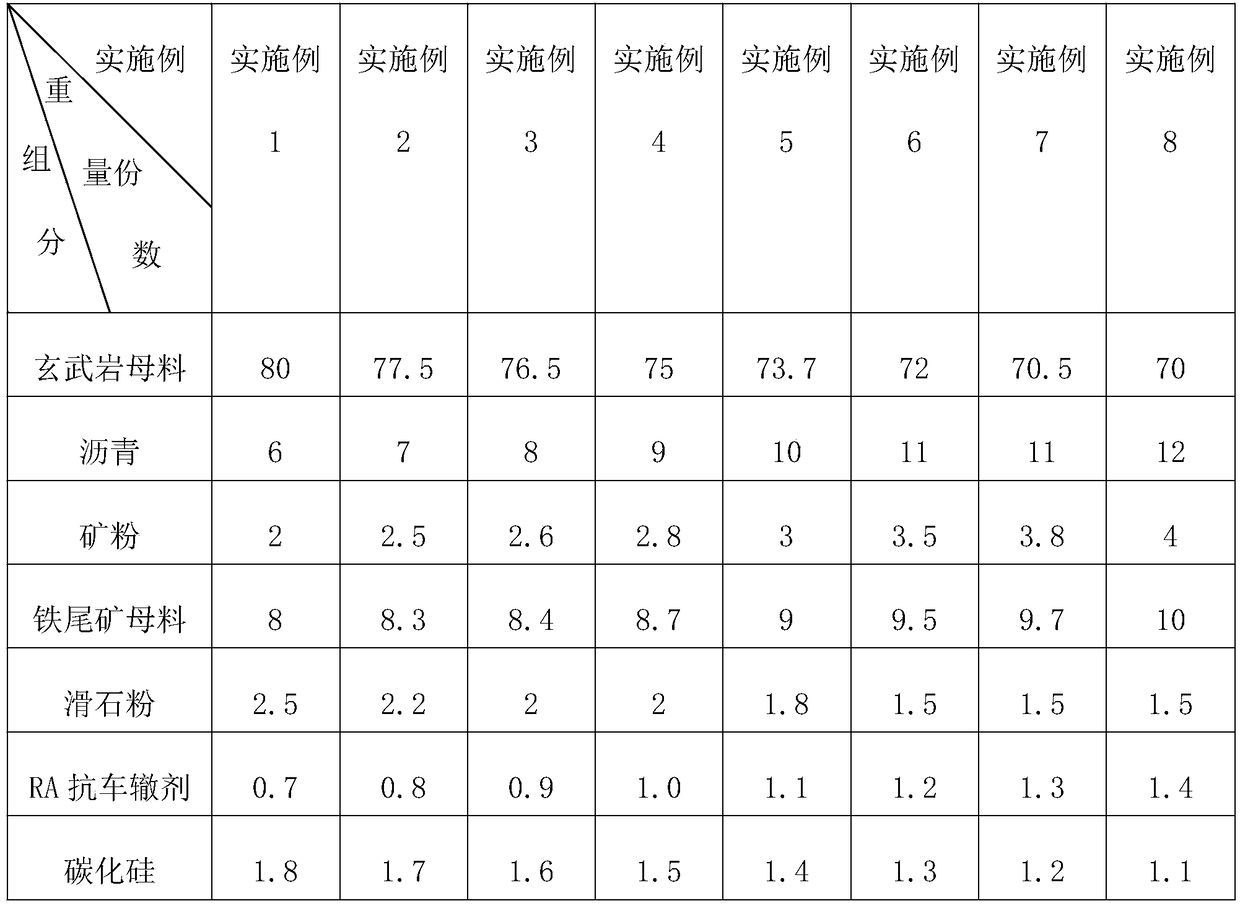

[0059] Embodiment 2-8: an asphalt concrete, the difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0060] Each component and parts by weight thereof in table 1 embodiment 1-8

[0061]

Embodiment 9

[0062] Embodiment 9: a kind of asphalt concrete, the difference from embodiment 1 is that the talcum powder in step 3 is replaced by dolomite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com