Water-proof and mildew-proof agent for artificial board and preparation method thereof

An anti-mold agent and technology for wood-based panels, applied in the field of additives for wood-based panels and their preparation, can solve the problems of fast instantaneous water absorption, easy to mold, difficult to apply, etc. Remarkable effect of anti-mold performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

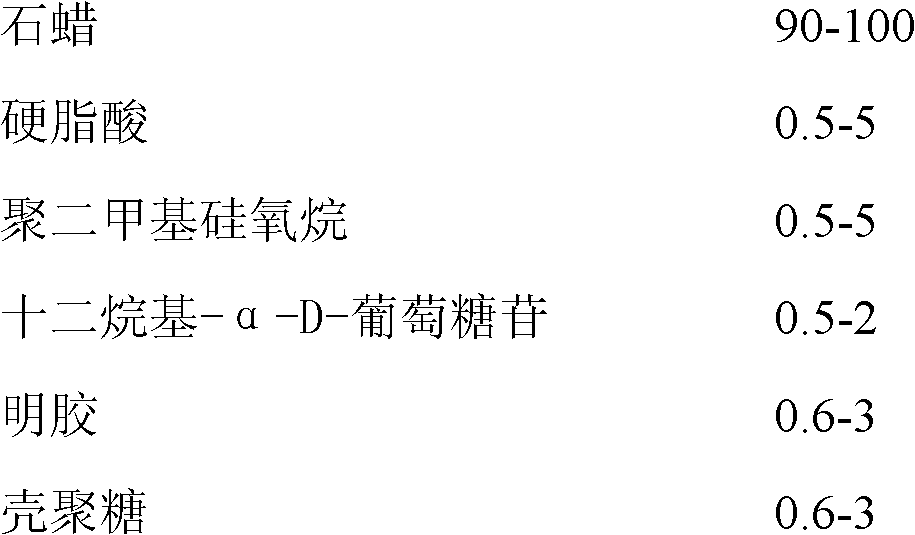

[0086] 1. Prepare raw materials according to the following weight (×100g)

[0087]

[0088] 2. The capsule core raw material paraffin, stearic acid and polydimethylsiloxane are mixed, heated to 70-80° C., melted, and mixed uniformly to obtain a molten capsule core pretreatment material.

[0089]3. Add gelatin, which is one of the raw materials of the capsule shell, and dodecyl-α-D-glucoside, which acts as a surfactant, into deionized water at 70°C, stir and dissolve evenly, and make a gelatin-surfactant solution for later use , wherein the weight ratio of gelatin to deionized water is 2:50, and the weight ratio of dodecyl-α-D-glucoside to deionized water is 0.5:50.

[0090] 4. Add chitosan, one of the capsule shell raw materials, into the acetic acid solution, stir, dissolve, and mix well to make a chitosan-acetic acid solution, wherein the mass percentage concentration of the acetic acid solution is 3%, and the chitosan and The weight ratio of the acetic acid solution is ...

Embodiment 2

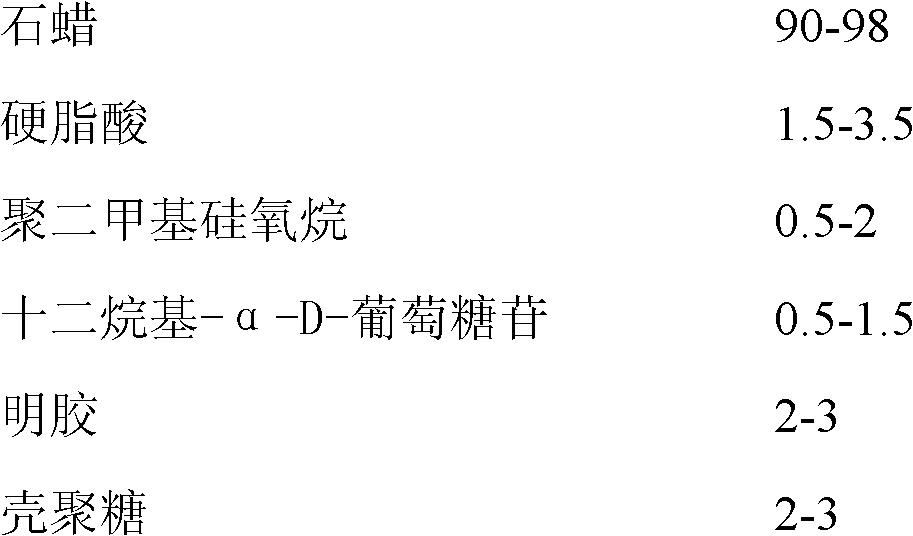

[0096] 1. Prepare raw materials according to the following weight (×100g)

[0097]

[0098] Except that the temperature of deionized water in step 3 is 80°C, the weight ratio of gelatin to deionized water is 0.6:50; the weight ratio of chitosan to acetic acid solution in step 4 is 2.5:50; The rotation speed is 10000rpm, the emulsification temperature is 75°C, the absolute pressure is 86KPa, and the emulsification time is 20min; the stirring speed described in step 6 is 10000rpm, the temperature is 75°C, the absolute pressure is 86KPa, the stirring time is 10min, and the temperature after cooling is 5 ℃, the cooling and cooling rate is 23.3 ℃ / min; the mass percent concentration of sodium hydroxide solution described in step 7 is 9% except that all the other are the same as in Example 1, and the prepared waterproof and mildew-proof capsule nanocapsule dispersion liquid adopts The particle size of the prepared waterproof and mildew-proof capsules was measured by a laser partic...

Embodiment 3

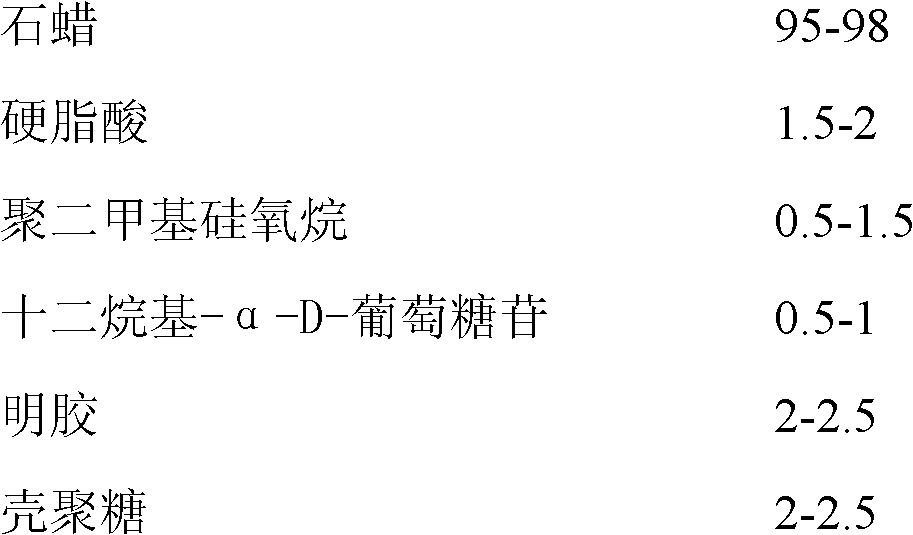

[0100] 1. Prepare raw materials according to the following weight (×100g)

[0101]

[0102] Except that the weight ratio of gelatin to deionized water in step 3 is 2.5:50, the weight ratio of dodecyl-α-D-glucoside to deionized water is 2:50; the mass percentage of acetic acid solution in step 4 The concentration is 4%; the rotating speed described in step 5 is 20000rpm, the emulsification temperature is 80°C, and the absolute pressure is 70KPa; in the step 6, the stirring rate is 20000rpm, the temperature is 80°C, the absolute pressure is 70KPa, and the temperature after cooling is 10°C. The cooling and cooling time is 2min, and the cooling and cooling rate is 35°C / min; except that the mass percent concentration of the sodium hydroxide solution described in step 7 is 11%, the rest are the same as in Example 1, and the prepared waterproof and mildew-proof capsule nano The particle size of the waterproof and anti-mildew capsules obtained by measuring the capsule dispersion wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com