A method to improve the durability of fast-growing wood furniture

A kind of durability and wood technology, which is applied in the direction of wood processing equipment, wood impregnation, impregnated wood, etc., can solve the problems of unfavorable fast-growing wood furniture development, soft wood, limited application, etc., and achieve general processing performance, waterproof and flame retardancy The effect of improving and improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

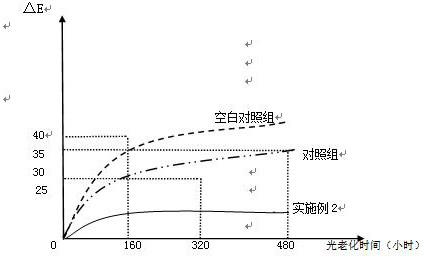

Image

Examples

Embodiment 1

[0017] A method for improving the durability of fast-growing wood furniture. The prepared silane-modified polyether emulsion and silica sol are used to prepare a fast-growing wood impregnation treatment solution, which is subjected to hydrothermal pressure impregnation to obtain modified fast-growing wood for further processing to prepare wooden furniture;

[0018] Concretely, the preparation method of modified fast-growing wood comprises the following process steps:

[0019] S1: Preparation of silane-modified polyether emulsion: Measure 170 ml of deionized water into a beaker, place it on a magnetic stirrer to preheat to 44°C, add 5 g of polyethylene glycol and 2 g of maleic anhydride to the beaker, Stir until the solid dissolves, then add 30 ml of polyether aqueous solution with a mass concentration of 20% to the beaker, stir and mix evenly, transfer the mixture to a three-necked flask, add 0.4 gram of wetting agent and 0.2 gram of emulsifier to the flask, stir Mix evenly an...

Embodiment 2

[0023] A method for improving the durability of fast-growing wood furniture. The prepared silane-modified polyether emulsion and silica sol are used to prepare a fast-growing wood impregnation treatment solution, which is subjected to hydrothermal pressure impregnation to obtain modified fast-growing wood for further processing to prepare wooden furniture;

[0024] Concretely, the preparation method of modified fast-growing wood comprises the following process steps:

[0025] S1: Preparation of silane-modified polyether emulsion: Measure 175 ml of deionized water into a beaker, place it on a magnetic stirrer to preheat to 45°C, add 5.5 g of polyethylene glycol and 2.5 g of maleic anhydride to the beaker, Stir until the solid dissolves, then add 32 ml of polyether aqueous solution with a mass concentration of 21% to the beaker, stir and mix evenly, transfer the mixture to a three-necked flask, add 0.45 g of wetting agent and 0.25 g of emulsifier to the flask, stir Mix evenly an...

Embodiment 3

[0029] A method for improving the durability of fast-growing wood furniture. The prepared silane-modified polyether emulsion and silica sol are used to prepare a fast-growing wood impregnation treatment solution, which is subjected to hydrothermal pressure impregnation to obtain modified fast-growing wood for further processing to prepare wooden furniture;

[0030] Concretely, the preparation method of modified fast-growing wood comprises the following process steps:

[0031] S1: Preparation of silane-modified polyether emulsion: Measure 180 ml of deionized water into a beaker, place it on a magnetic stirrer to preheat to 46°C, add 6 g of polyethylene glycol and 3 g of maleic anhydride to the beaker, Stir until the solid dissolves, then add 35 ml of polyether aqueous solution with a mass concentration of 22% to the beaker, stir and mix evenly, transfer the mixture to a three-necked flask, add 0.5 gram of wetting agent and 0.3 gram of emulsifier to the flask, stir Mix evenly an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com