A kind of anti-compression and anti-deformation thermal insulation material for furniture production

A technology for thermal insulation materials and furniture, which is applied in the field of compression-resistant and deformation-resistant thermal insulation materials for furniture production. It can solve the problems of service performance and service life discount, general aging resistance performance, general thermal insulation effect, etc., and achieve excellent service performance and service life, fire prevention The effect of excellent performance and outstanding mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

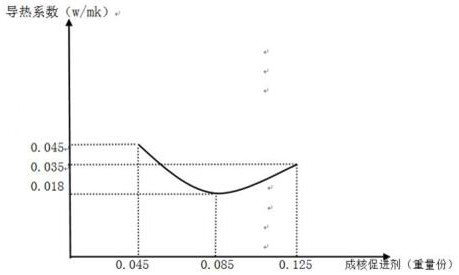

Image

Examples

Embodiment 1

[0016] A pressure-resistant and deformation-resistant thermal insulation material for furniture production, which uses acrylonitrile and methacrylic acid as monomers, adds a prepared nucleation accelerator, and performs prepolymerization to obtain a prepolymer that is further foamed at a high temperature to obtain the pressure-resistant and heat-resistant insulation material. Modified insulation materials;

[0017] Specifically, the preparation method of the thermal insulation material includes the following process steps:

[0018] S1: Preparation of nucleation accelerator: Weigh 13.5 millimolar manganese acetate tetrahydrate, 2.8 grams of sodium metaaluminate, and 5.5 grams of cobalt sulfate in a beaker, add 85 milliliters of deionized water to the beaker, and heat at 300 rpm The speed was continuously stirred for 20 minutes, and then 10 milliliters of citric acid solution with a mass concentration of 2.0% and 15 milliliters of ethylene glycol solution with a mass concentrati...

Embodiment 2

[0021] A pressure-resistant and deformation-resistant thermal insulation material for furniture production, which uses acrylonitrile and methacrylic acid as monomers, adds a prepared nucleation accelerator, and performs prepolymerization to obtain a prepolymer that is further foamed at a high temperature to obtain the pressure-resistant and heat-resistant insulation material. Modified insulation materials;

[0022] Specifically, the preparation method of the thermal insulation material includes the following process steps:

[0023] S1: Preparation of nucleation accelerator: Weigh 13.8 millimolar manganese acetate tetrahydrate, 2.9 grams of sodium metaaluminate, and 5.8 grams of cobalt sulfate in a beaker, add 88 milliliters of deionized water to the beaker, and heat at 320 rpm The speed was continuously stirred for 25 minutes, then 11 milliliters of citric acid solution with a mass concentration of 2.5% and 16 milliliters of ethylene glycol solution with a mass concentration o...

Embodiment 3

[0026] A pressure-resistant and deformation-resistant thermal insulation material for furniture production, which uses acrylonitrile and methacrylic acid as monomers, adds a prepared nucleation accelerator, and performs prepolymerization to obtain a prepolymer that is further foamed at a high temperature to obtain the pressure-resistant and heat-resistant insulation material. Modified insulation material;

[0027] Specifically, the preparation method of the thermal insulation material includes the following process steps:

[0028]S1: Preparation of nucleation accelerator: Weigh 14.0 millimolar manganese acetate tetrahydrate, 3.0 grams of sodium metaaluminate, and 6.0 grams of cobalt sulfate in a beaker, add 90 milliliters of deionized water to the beaker, and spin at 340 rpm The speed was continuously stirred for 30 minutes, then 12 milliliters of citric acid solution with a mass concentration of 3.0% and 18 milliliters of ethylene glycol solution with a mass concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com