Method for manufacturing medium and high density fiberboards without pre-cured layers

A technology of high-density fiberboard and pre-cured layer, which is applied in the direction of flat products, household components, household appliances, etc., can solve the problems of large production scale and production capacity, and achieve the effects of improving utilization rate, improving market adaptability, and reducing raw material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

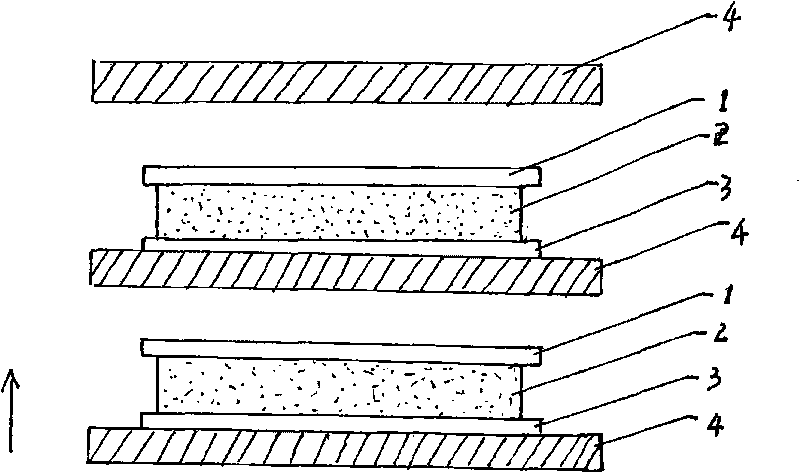

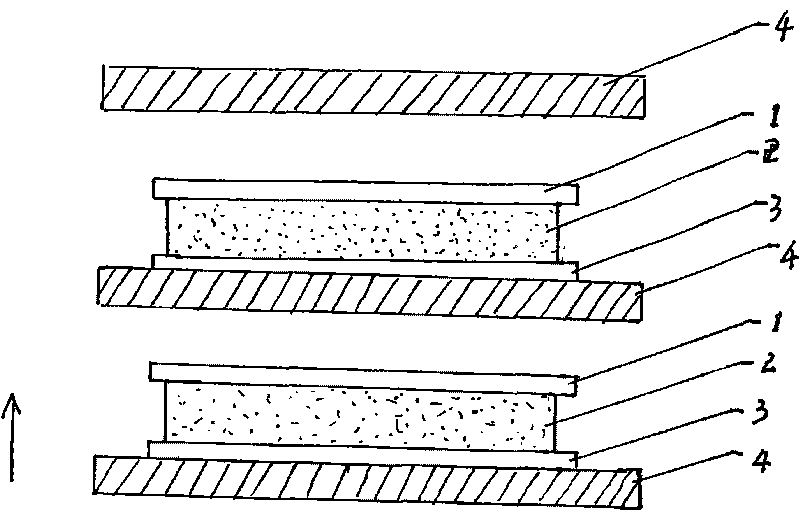

[0020] Embodiment 1: multi-layer pressing machine pressing thickness 20mm, density 0.70g / cm 3 MDF. Lay fiber slabs with the required thickness and weight, pre-press and saw them longitudinally and crosswise to obtain each fiber slab, transport the fiber slabs to the transport line of the delayed heat transfer plate, and place the other delay heat transfer plate Placed on the fiber base plate, transported to the board feeding device together, and loaded into each layer of the hot plate of the multi-layer hot press, according to the hot pressing process, closed pressing. Push the pressed slab and delayed heat transfer plate out of the press to obtain a slab with no or less pre-cured layer, unload the plate with the plate unloader, separate the slab and delayed heat transfer plate, cool, trim the slab, sand Light, that is, get the desired product.

Embodiment 2

[0021] Embodiment 2: multi-layer press pressing thickness 8mm, density 0.9g / cm 3 of high-density fiberboard. Others are the same as in Example 1, the amount of fiber slab paving and the adjustment of hot pressing parameters.

Embodiment 3

[0022] Embodiment 3: multi-layer pressing machine pressing thickness 2mm, density 1.0g / cm 3 The high-density fiberboard, others are adjusted with embodiment 2, fiber paving amount and hot-pressing parameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com