Friction plate material and preparation method thereof

A friction lining and filler technology, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve problems such as poor high temperature resistance, and achieve the effects of improving internal bonding strength, prolonging service life, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

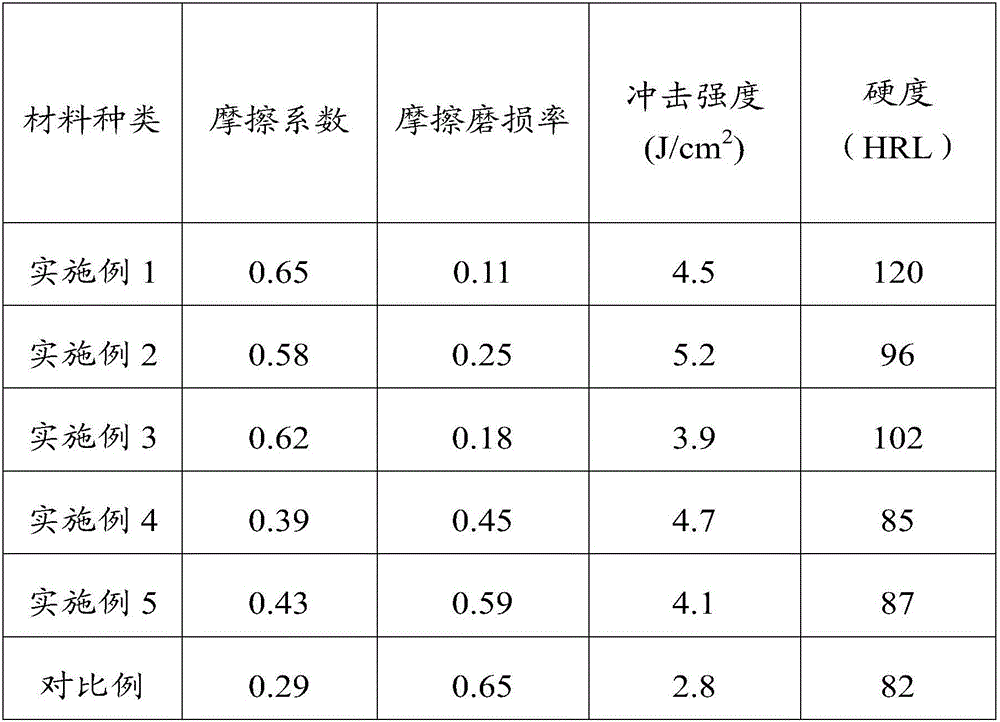

Examples

Embodiment 1

[0034] A friction plate material and its preparation method

[0035] Friction plate material raw material composition: (unit: kg)

[0036] Enhanced foam alloy: aluminum alloy powder 8.5, tungsten carbide 0.45, titanium hydride 0.26;

[0037] Filling materials: modified fiber 35, phenolic resin 8, wear-resistant modifier 15, diatomaceous earth 6, brass powder 3, graphite 3, carbon fiber 3, silicon dioxide 2.

[0038] Prepared by:

[0039] Step S10, preparation of modified fiber:

[0040] Step S11, putting the emulsifier fatty alcohol polyoxyethylene ether into absolute ethanol, mixing and stirring for 1.5 hours to obtain an emulsion of fatty alcohol polyoxyethylene ether;

[0041] Step S12, adding the modifying agent phthalic anhydride into the emulsion, and continuing to stir and mix for 30 minutes;

[0042] Step S13, adding resin fibers, continuing to stir and mix for 3 hours, and standing still at room temperature for 22 hours;

[0043] Step S14, taking out the resin fi...

Embodiment 2

[0054] A friction plate material and its preparation method

[0055] Friction plate material raw material composition: (unit: kg)

[0056] Enhanced foam alloy: aluminum alloy powder 8, tungsten carbide 0.1, titanium hydride 0.2;

[0057] Filler: modified fiber 30, phenolic resin 10, wear-resistant modifier 20, diatomaceous earth 3, brass powder 5, graphite 1, carbon fiber 1, silicon dioxide 5.

[0058] Prepared by:

[0059] Step S10, preparation of modified fiber:

[0060] Step S11, putting the emulsifier fatty alcohol polyoxyethylene ether into absolute ethanol, mixing and stirring for 1 hour to obtain an emulsion of fatty alcohol polyoxyethylene ether;

[0061] Step S12, adding the modifying agent phthalic anhydride into the emulsion, and continuing to stir and mix for 30 minutes;

[0062] Step S13, add resin fibers, continue to stir and mix for 2 hours, and stand still at room temperature for 24 hours;

[0063] Step S14, taking out the resin fiber and curing to obtain ...

Embodiment 3

[0074] A friction plate material and its preparation method

[0075] Friction plate material raw material composition: (unit: kg)

[0076] Enhanced foam alloy: aluminum alloy powder 9, tungsten carbide 0.8, titanium hydride 0.08;

[0077] Filler: modified fiber 40, phenolic resin 5, wear-resistant modifier 10, diatomaceous earth 8, brass powder 1, graphite 5, carbon fiber 5, silicon dioxide 1.

[0078] Prepared by:

[0079] Step S10, preparation of modified fiber:

[0080] Step S11, putting the emulsifier fatty alcohol polyoxyethylene ether into absolute ethanol, mixing and stirring for 1 hour to obtain an emulsion of fatty alcohol polyoxyethylene ether;

[0081] Step S12, adding the modifying agent phthalic anhydride into the emulsion, and continuing to stir and mix for 30 minutes;

[0082] Step S13, add resin fibers, continue stirring and mixing for 1 hour, and stand still at room temperature for 20 hours;

[0083] Step S14, taking out the resin fiber and curing to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com