Emulsified paraffin for wood processing and preparation method thereof

A technology for emulsifying paraffin and wood, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor stability and dispersion, large emulsified paraffin particles, and poor emulsion stability, achieving good stability, low cost, and high dispersion good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

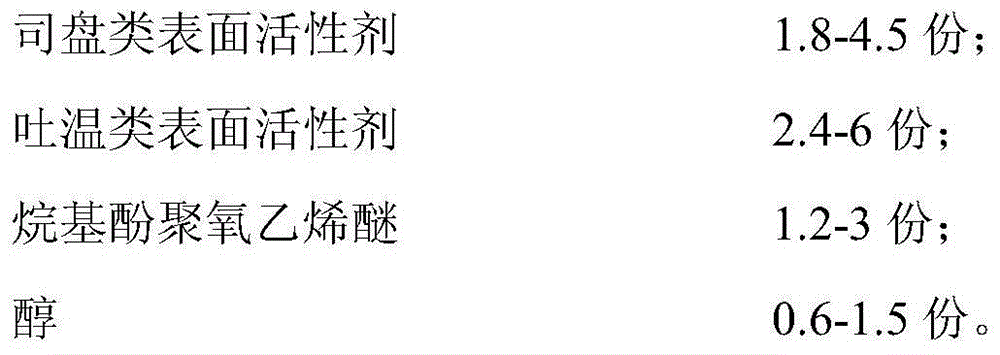

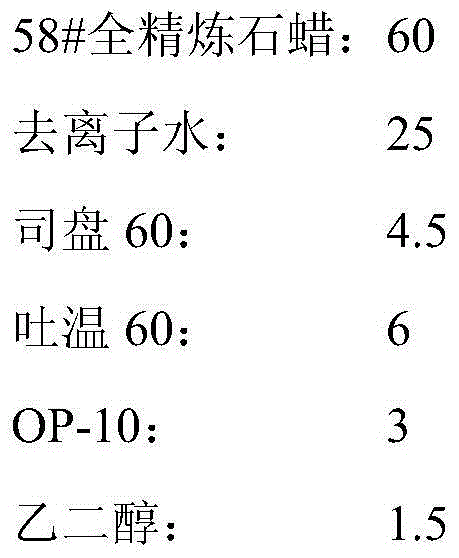

[0043] (1) Raw material ratio (components by weight):

[0044]

[0045] (2) Put Span 60, Tween 60, OP-10 and ethylene glycol into the reaction kettle, stir and mix evenly to make a compound emulsifier;

[0046] (3) Put the fully refined paraffin into the reaction kettle to heat and melt, the heating temperature is 75°C, add the compound emulsifier and stir at the speed of 800r / min, and mix well;

[0047] (4) At a stirring speed of 800r / min, slowly add 5 parts by weight of water at 75°C and stir for 5 minutes to form a W / O phase emulsion;

[0048] (5) Continue to slowly add 10 parts by weight of water at 75°C, stir at a speed of 800r / min for 10min, and invert the phase to form an O / D phase emulsion;

[0049] (6) Continue to slowly add 10 parts by weight of water at 75° C., and stir at a speed of 800 r / min for 25 minutes to form a stable O / W phase emulsion, that is, to obtain a stable emulsified paraffin wax.

[0050] When the emulsified paraffin is dropped into water, it c...

Embodiment 2

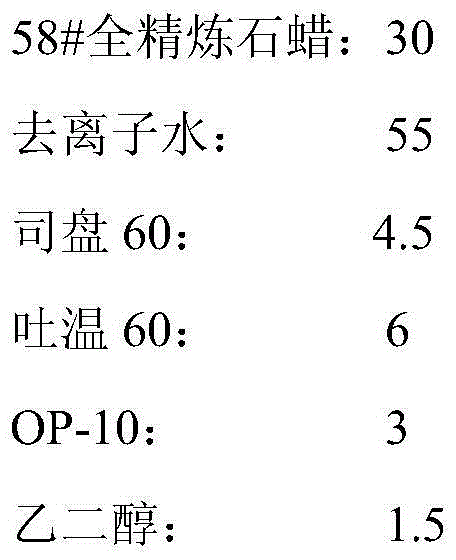

[0054] (1) Raw material ratio (components by weight):

[0055]

[0056] (2) Put Span 60, Tween 60, OP-10 and ethylene glycol into the reaction kettle, stir and mix evenly to make a compound emulsifier;

[0057] (3) Put the fully refined paraffin into the reaction kettle to heat and melt, the heating temperature is 75°C, add the compound emulsifier and stir at the speed of 800r / min, and mix well;

[0058] (4) At a stirring speed of 800r / min, slowly add 10 parts by weight of water at 75°C and stir for 5 minutes to form a W / O phase emulsion;

[0059] (5) Continue to slowly add 20 parts by weight of water at 75°C, stir at a speed of 800r / min for 10min, and invert the phase to form an O / D phase emulsion;

[0060] (6) Continue to slowly add 25 parts by weight of water at 75° C., and stir at a speed of 800 r / min for 25 minutes to form a stable O / W phase emulsion, that is, to obtain a stable emulsified paraffin wax.

[0061] When the emulsified paraffin is dropped into water, it ...

Embodiment 3

[0065] (1) Raw material ratio (components by weight):

[0066]

[0067] (2) Put Span 60, Tween 60, OP-10 and ethylene glycol into the reaction kettle, stir and mix evenly to make a compound emulsifier;

[0068] (3) Put the fully refined paraffin into the reaction kettle to heat and melt, the heating temperature is 75°C, add the compound emulsifier and stir at the speed of 800r / min, and mix well;

[0069] (4) At a stirring speed of 800r / min, slowly add 10 parts by weight of water at 75°C and stir for 5 minutes to form a W / O phase emulsion;

[0070] (5) Continue to slowly add 20 parts by weight of water at 75°C, stir at a speed of 800r / min for 10min, and invert the phase to form an O / D phase emulsion;

[0071] (6) Continue to slowly add 25 parts by weight of water at 75° C., and stir at a speed of 800 r / min for 25 minutes to form a stable O / W phase emulsion, that is, to obtain a stable emulsified paraffin wax.

[0072] When the emulsified paraffin is dropped into water, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com