Preparation method and application in wood processing of water-based polyurethane adhesive

A water-based polyurethane and adhesive technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of high solvent content and poor water resistance, and achieve reduced system viscosity, strong adaptability, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

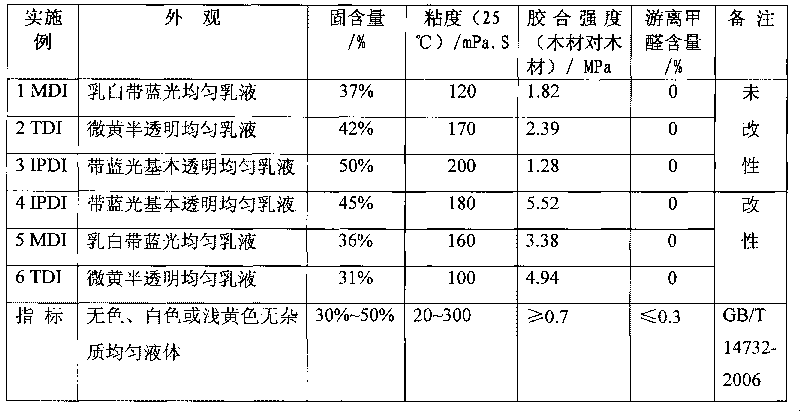

Examples

Embodiment 1

[0024] Add 21.85g of polyadipate-1,4-butylene glycol ester diol (PBA-2000) and 1.6g of DMPA into a three-necked flask, mix and stir after melting, vacuumize and dehydrate at 90°C for 1 hour, and the vacuum degree is 0.095MPa . Then cool down to 80°C and add 1.9g NMP (1-methyl-2-pyrrolidone), 0.76g HEA (hydroxyethyl acrylate), 7.25g MDI and catalyst: di-n-butyltin dilaurate, 0.1g, and heat the reaction until the system When the NCO value basically reaches the theoretical value, the prepolymer is obtained, and the temperature begins to drop. Cool the prepolymer to 60°C, dilute it with an appropriate amount of acetone, and after the viscosity decreases, add 1.2g triethylamine dropwise for shear emulsification and neutralization for 30 minutes to form a salt, after the phase transition is basically completed. 58.9 g of water was added under high-speed stirring, and then 0.048 g of chain extender ethylenediamine was slowly added dropwise for further chain extension and emulsificat...

Embodiment 2

[0026] Under the operation condition of embodiment 1, add 2g castor oil (C.O.) in addition, change MDI into TDI, its NCO / OH ratio (R) is 1.4, obtains yellowish emulsion (theoretical solid content is 42%).

Embodiment 3

[0028]Under the operating conditions of Example 1, MDI was replaced by IPDI, the R value was 1.2, and a slightly blue translucent emulsion (theoretical solid content was 50%) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com