Assistant treatment device for wood processing

An auxiliary processing and wood technology, applied in the direction of wood processing appliances, manufacturing tools, special forming/shaping machines, etc., can solve problems affecting work efficiency, liberating manpower, work fatigue, etc., to reduce potential safety hazards, improve work efficiency, The effect of avoiding indirect contact

Inactive Publication Date: 2017-02-15

CHENGDU PUJIANG KEXIAN TECH

View PDF8 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] When reproducing and processing, the wood will be cut, and the wood will be cut into a suitable length. The traditional method is to cut it manually, which is time-consuming and labor-intensive. Work fatigue will occur after a long time of work. Some existing cutting devices, although functional It is powerful but cannot liberate manpower very well. It needs to be manually loaded during cutting, which has potential safety hazards and affects work efficiency. In view of this, the inventor of this case conducted in-depth research on the above problems, and this case came into being.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0023] Embodiment 2: The anti-slip layer of this device can be replaced by a sponge layer, which also achieves the same effect, and its structure is the same as that of Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

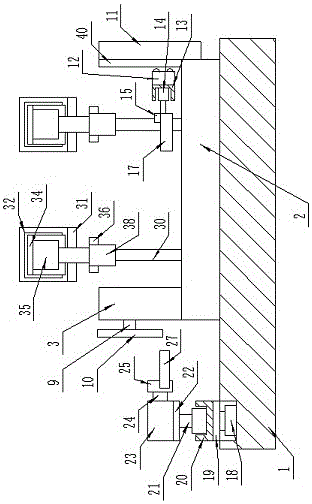

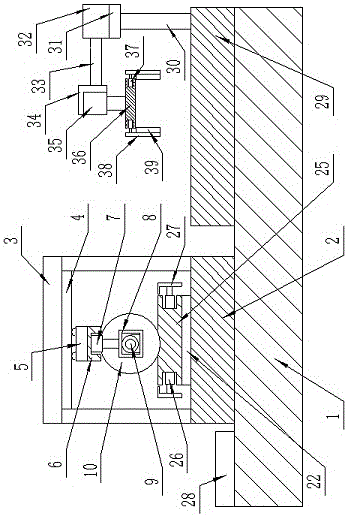

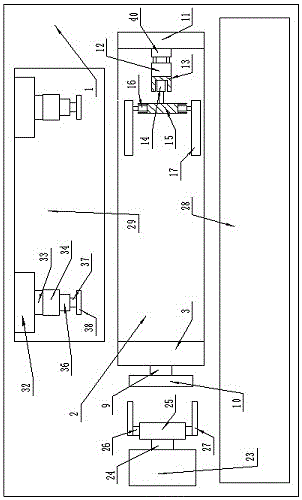

The invention discloses an assistant treatment device for wood processing. The assistant treatment device comprises a working table, wherein a carrying mechanism and a fixed cutting mechanism are arranged on the upper surface of the working table; a No.4 round groove is processed on the upper surface of the working table and is positioned on one side of a placing platform; a No.4 driving part with an upward driving end is arranged on the lower surface in the No.4 round groove; a No.1 support plate is arranged at the driving end of the No.4 driving part; a No.3 mounting block is arranged on the upper surface of the No.1 support plate; a No.5 round groove is processed on the upper surface of the No.3 mounting block; a No.2 pushing cylinder with an upward telescopic end is arranged on the lower surface in the No.5 round groove; a carrier plate is arranged on the telescopic end of the No.2 pushing cylinder; and a No.2 mouth-shaped mounting rack is arranged on the upper surface of the carrier plate. The assistant treatment device disclosed by the invention has the beneficial effects of achieving automatic feeding, improving the working efficiency, and automatically propelling cutting.

Description

technical field [0001] The invention relates to the auxiliary field of wood processing, in particular to an auxiliary processing device for wood processing. Background technique [0002] A log is a piece of wood cut to a certain length along the length of the original strip according to the size, shape, and quality standards or special regulations. It is generally stipulated that the length of the material should not exceed 12m or 40 feet, and it has great uses in many aspects such as construction, furniture, craft carving and papermaking. [0003] When reproducing and processing, the wood will be cut, and the wood will be cut into a suitable length. The traditional method is to cut it manually, which is time-consuming and labor-intensive. Work fatigue will occur after a long time of work. Some existing cutting devices, although functional It is powerful but cannot liberate manpower very well. It needs to be manually loaded during cutting, which has potential safety hazards...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27C5/02B27C5/06

CPCB27C5/02B27C5/06

Inventor 陈清尧

Owner CHENGDU PUJIANG KEXIAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com