Cantilever type wood compound processing center

A compound machining center and cantilever-type technology, which is applied in the direction of wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve the problems of high cost and affecting processing efficiency, so as to reduce production costs, improve production efficiency, and avoid cumbersome steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

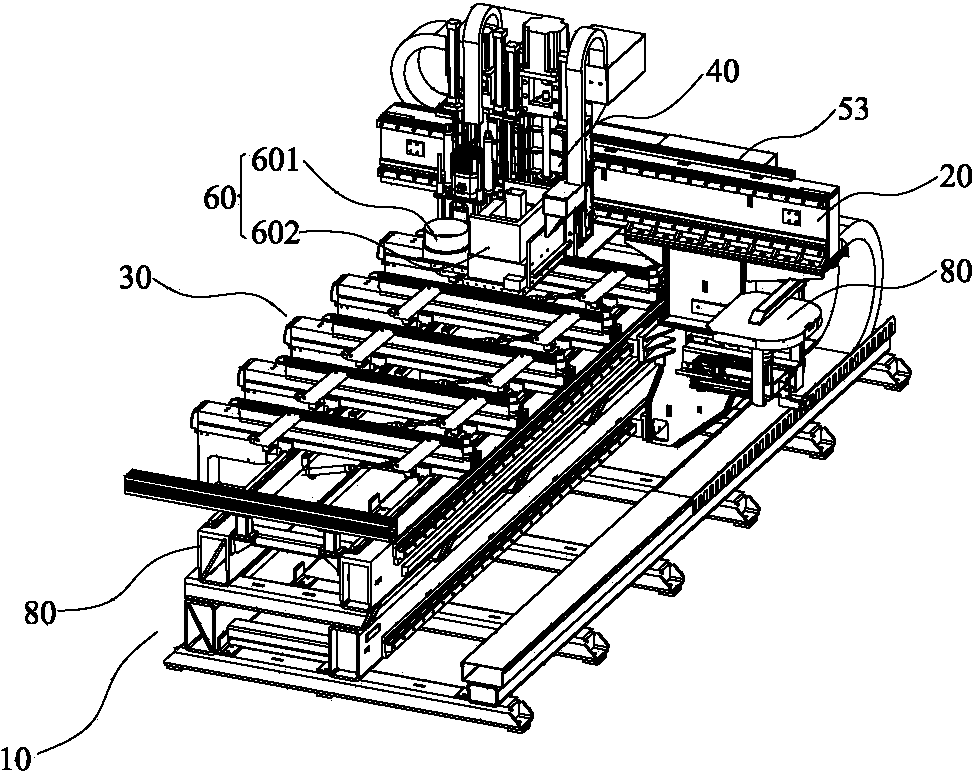

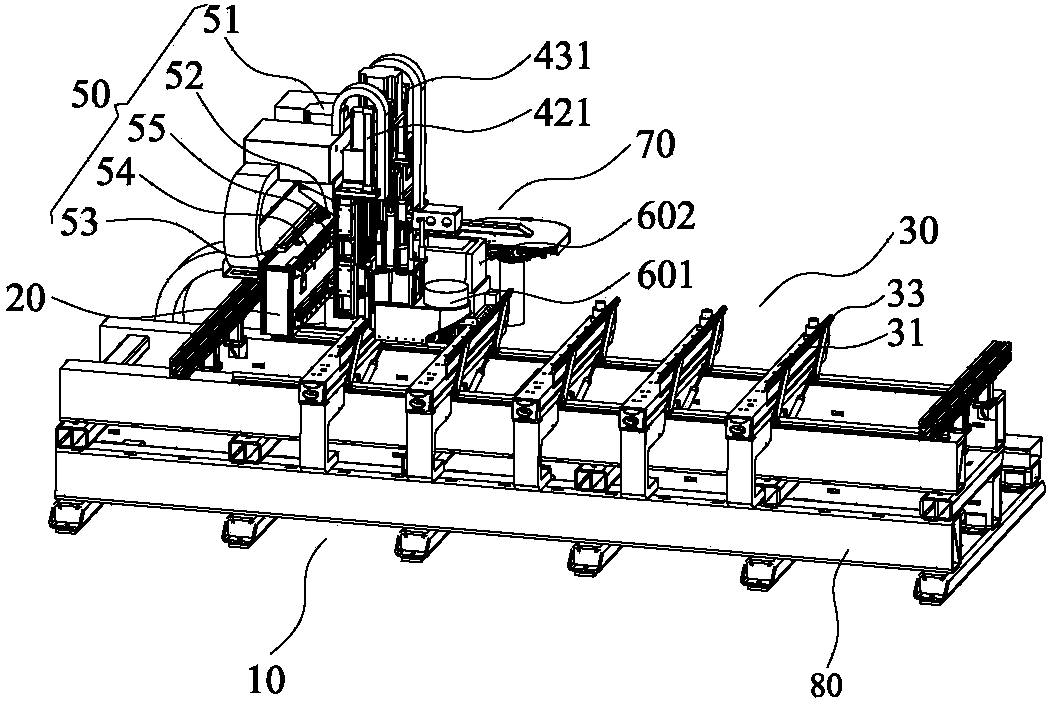

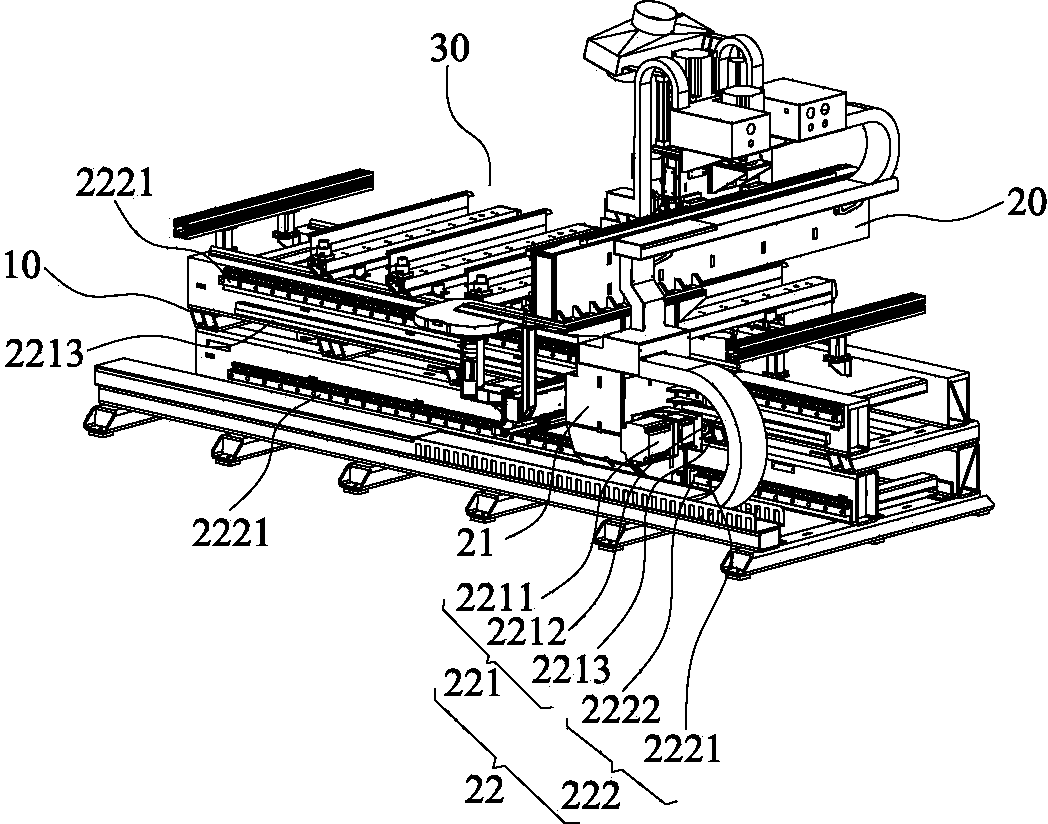

[0080] The invention as Figure 1 to Figure 17 As shown, a cantilever wood composite machining center includes

[0081] Base 10, beam 20, movable workbench 30, vertical moving device 40, lateral moving device 50, wood processing device 60 and tool magazine 70, wherein,

[0082] The base 10 is formed by a plurality of rectangular beams 80;

[0083] One end of the crossbeam 20 has a support arm 21 arranged downward, and the other end of the crossbeam 20 relies on the support arm 21 to straddle above the base 10; Longitudinal moving device 22; the longitudinal moving device 22 includes a longitudinal driving part 221 and a longitudinal sliding part 222, wherein the longitudinal driving part 221 includes a longitudinal driving motor 2211 mounted on the rear side of the above-mentioned support arm 21, a vertical driving motor 2211 mounted on the The longitudinal drive gear 2212 at the shaft end and the longitudinal drive rack 2213 fixed on the side wall of the base 10, the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com