Two-dimensional layered titanium carbide/metal ion composite material and application thereof

A metal ion, two-dimensional layered technology, which is applied in the field of two-dimensional layered titanium carbide/metal ion composite materials, can solve the problems that restrict the large-scale application of lithium-ion batteries, cumbersome preparation process, and few practical applications, and achieve rich surface The effect of active groups, good cycle performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

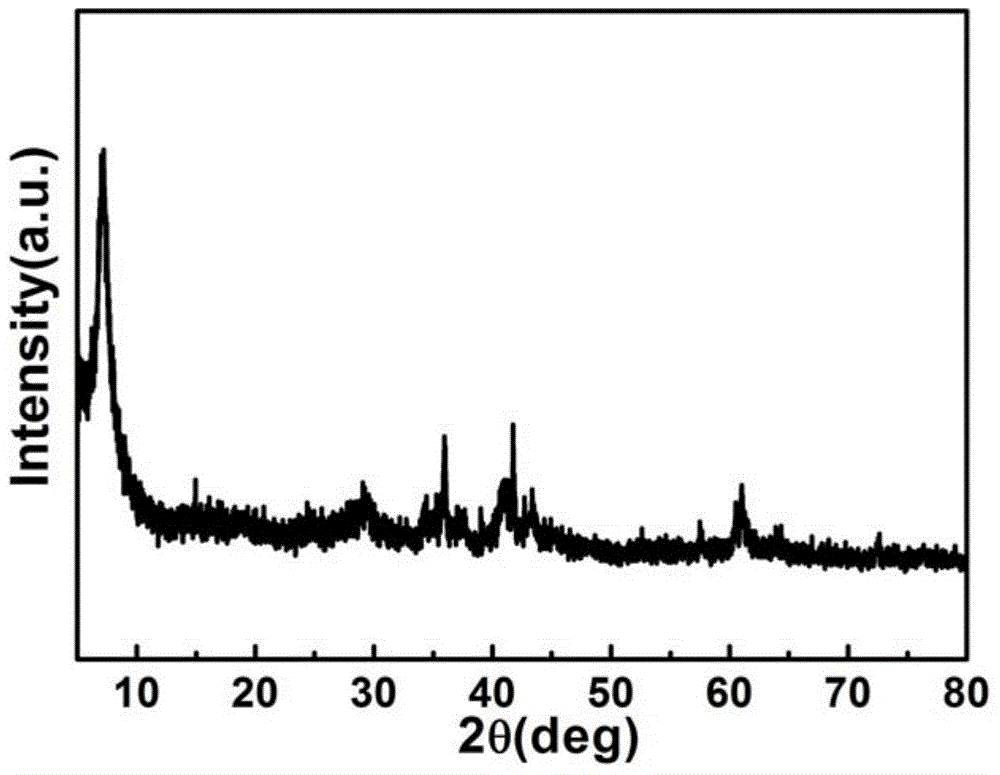

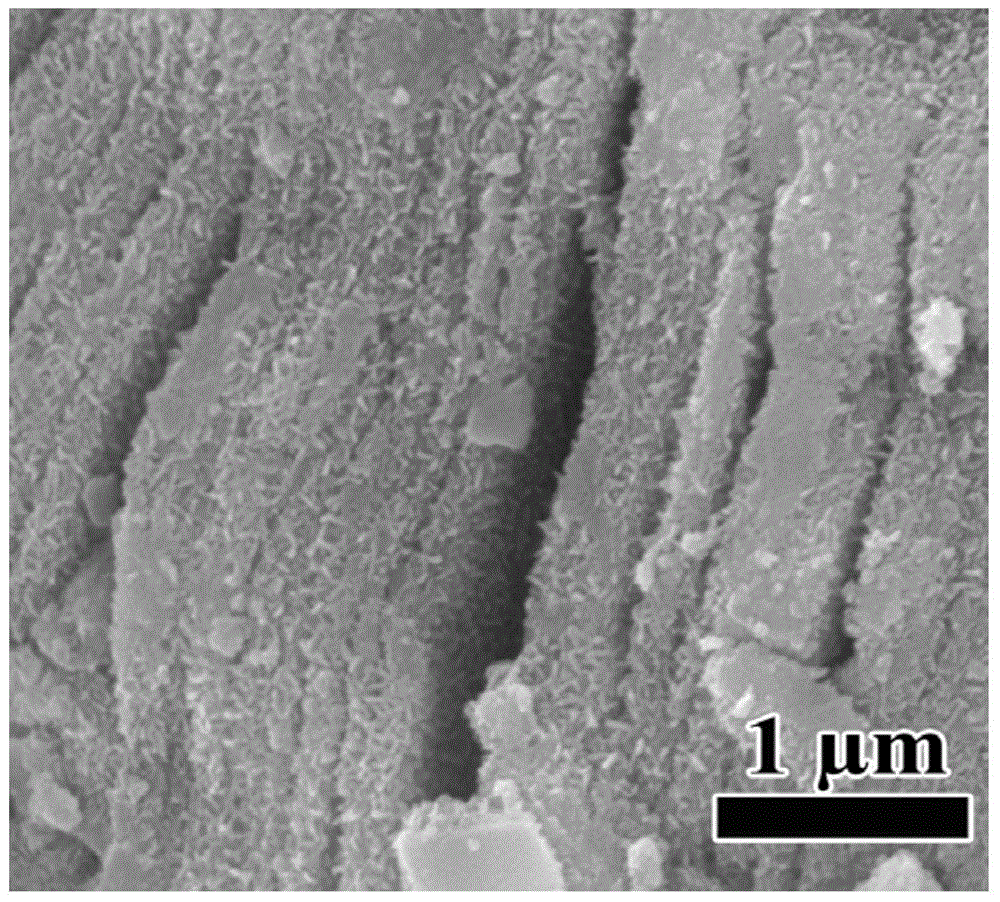

[0029] Take 1g Ti 3 AlC 2 Put the powder into a plastic beaker, add 20ml of HF solution with a mass fraction of 10%, and soak for 2h. Then the soaked powder was centrifuged, washed with deionized water until neutral, and baked in a blast oven at 80°C for 6 hours. The dried Ti 3 C 2 Powder, soak in 0.1mol / L sodium hydroxide solution for 8 hours, centrifuge, wash with deionized water until neutral, and dry. Ti 3 C 2 Soak the powder in 100ml of 0.05mol / L nickel nitrate solution, add 0.01g of surfactant PVP (polyvinylpyrrolidone) to soak for 12h, centrifuge, wash until neutral, and dry.

[0030] With the two-dimensional Ti prepared in Example 1 3 C 2 / Metal ion composite material powder is prepared as an electrode by the following method.

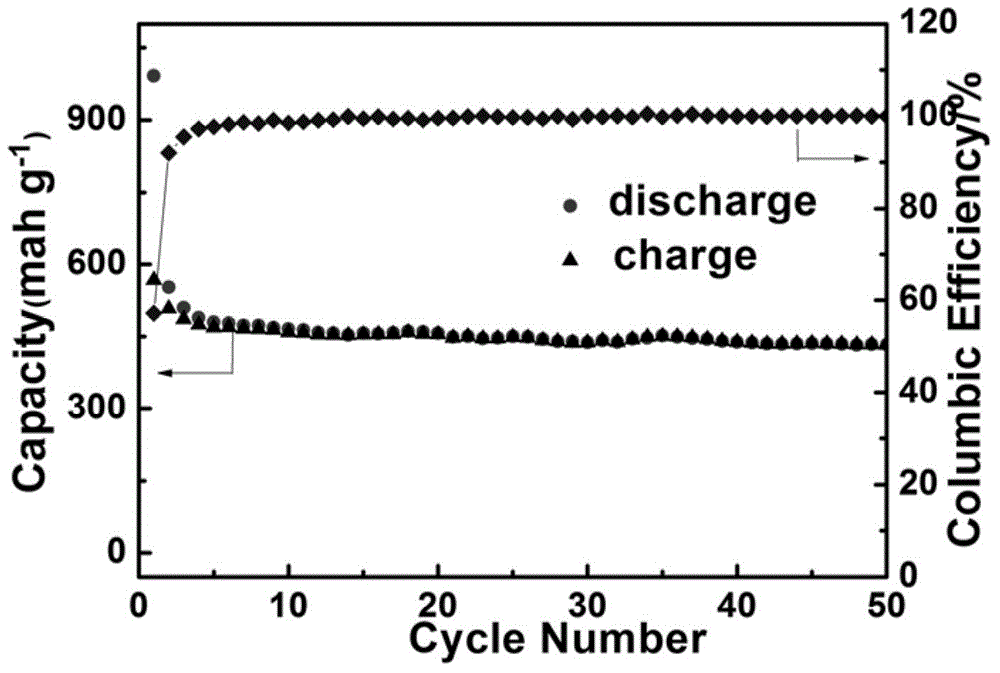

[0031] Weigh Ti respectively with a mass ratio of 80:10:10 3 C 2 / Metal ion composite material: super-P:PVDF, the electrode is made after uniform grinding, the metal lithium sheet is the positive electrode, and the electrolyte is 1mo...

Embodiment 2

[0033] Take 2g Ti 3 AlC 2 Put the powder into a plastic beaker, add 10ml of HF solution with a mass fraction of 30%, and soak for 8h. Then the soaked powder was centrifuged, washed with deionized water until neutral, and baked in a blast oven at 80°C for 24 hours. The dried Ti 3 C 2 Powder, soak in 5mol / L potassium hydroxide solution for 12h, centrifuge, wash until neutral, and dry. Ti 3 C 2 Soak the powder in 150ml of 0.2mol / L ferric chloride solution, add 2g of surfactant CTAB (cetyltrimethylammonium bromide) at the same time, soak for 24h, centrifuge, wash until neutral, and dry. The prepared two-dimensional titanium carbide / metal ion composite material is used to make electrodes according to the method of Example 1, and assembled into a lithium-ion battery. The discharge capacity after 50 cycles at a current density of 100ma / g is close to 415mAh / g. Good performance.

Embodiment 3

[0035] Take 4g Ti 3 AlC 2Put the powder into a plastic beaker, add 12.5ml of HF solution with a mass fraction of 70%, and soak for 48h. Then the soaked powder was centrifuged, washed with deionized water until neutral, and baked in a blast oven at 80°C for 12 hours. The dried Ti 3 C 2 Powder, soak in 0.3mol / L lithium hydroxide solution for 24h, centrifuge, wash until neutral, and dry. Then the dried Ti 3 C 2 Soak the powder in 200ml of 5mol / L tin chloride solution, add 3g of PVP (polyvinylpyrrolidone) at the same time, soak for 17h, centrifuge, wash until neutral, and dry. With the obtained two-dimensional titanium carbide / metal ion composite material, an electrode is made according to the method of Example 1, and a molded lithium ion battery is assembled, and the discharge capacity after 50 cycles at a current density of 100ma / g is close to 425mAh / g, Good cycle performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com