Preparation method and application of iron-nitrogen co-doped porous carbon sphere material

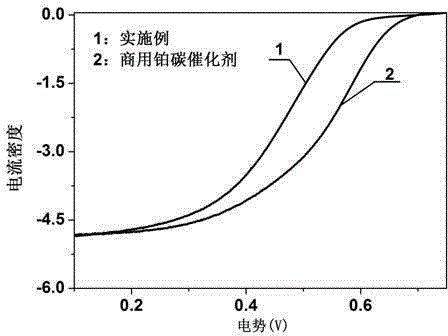

A technology of co-doping, porous carbon, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve the problems of expensive catalyst raw materials, unsatisfactory catalytic effect, harsh preparation conditions, etc. The effect of the specific surface area and the low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

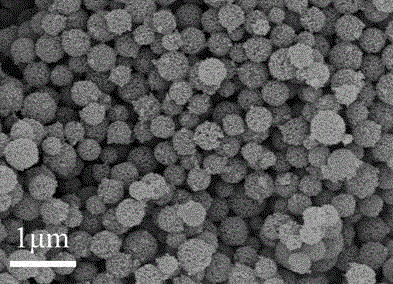

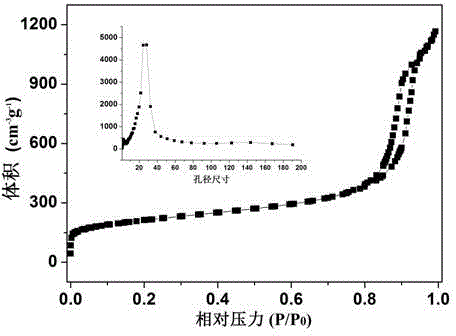

[0020] A method for preparing an iron-nitrogen co-doped porous carbon sphere material, the iron-nitrogen co-doped porous carbon sphere material has a high specific surface area and a large pore volume, contains a three-dimensional connected pore system, and the mesopore size is 20- 30 nm, the steps are as follows:

[0021] 1) Dissolve 10 mmol of 2-aminopyridine in 20 g of toluene, then add 0.7 g of porous silica spherical template, mix well, place in an ice-water bath, add 10 mmol of ammonium persulfate and 1 mmol of Ferric chloride, polymerized for 24 h, after standing still and centrifuging, the solid was dried at 120 °C for 12 h to obtain a brown precursor;

[0022] 2) Put 3 g of the above precursors into a quartz boat, pass inert gas nitrogen into the tube furnace for high-temperature carbonization at a heating rate of 2 °C, raise the temperature to 900 °C and carry out carbonization at the highest temperature for 2 h, and then Cool naturally to room temperature under nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com