Porous silicon carbon composite material and preparation method therefor

A carbon composite material and porous silicon technology, applied in the field of nanomaterials, can solve the problems of affecting the rate charge and discharge performance, large volume change, capacity attenuation of silicon anode materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0106] Specifically, the preparation method of the present invention comprises steps:

[0107] (1) Provide a silicon-active metal alloy;

[0108] (2) reacting the alloy with a liquid phase pore-forming agent to remove the active metal to obtain a porous silicon nanomaterial;

[0109] (3) cleaning the porous silicon nanomaterial with a hydrofluoric acid solution to remove silicon oxide, and obtaining a porous silicon nanomaterial cleaned with hydrofluoric acid;

[0110] (4) mixing the obtained nano-silicon material with the polymer and ball milling to obtain a homogeneous mixture of porous nano-silicon / polymer;

[0111] (5) Calcining the nano-silicon / polymer mixture to obtain a porous silicon-carbon composite material.

[0112] In another preferred embodiment, the above-mentioned polymer is added in a liquid form (such as suspension, dispersion, etc.).

[0113] In another preferred example, the silicon-active metal alloy is silicon-active metal alloy scrap. The silicon-acti...

Embodiment 1

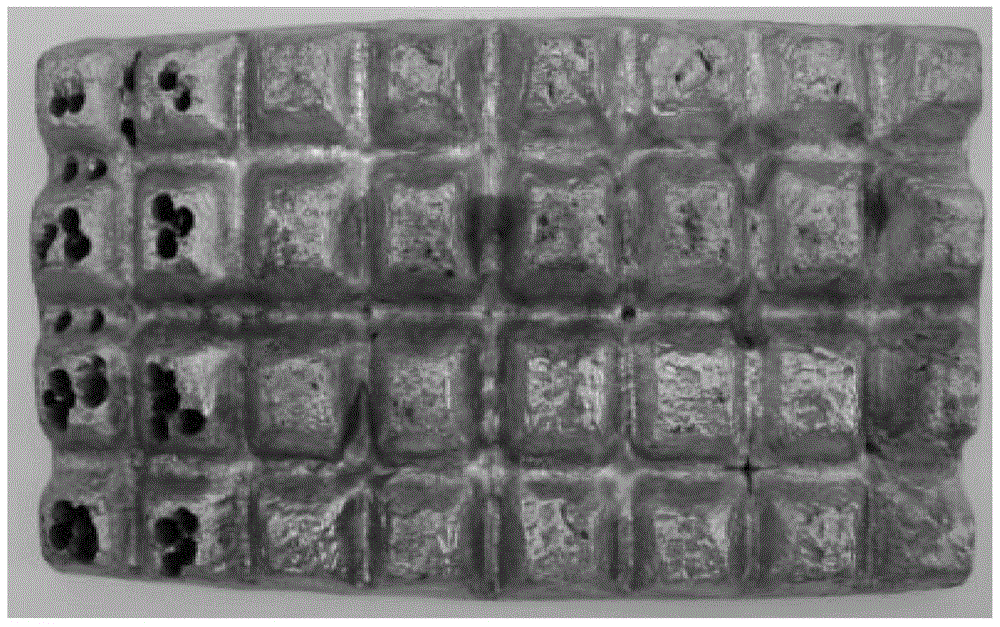

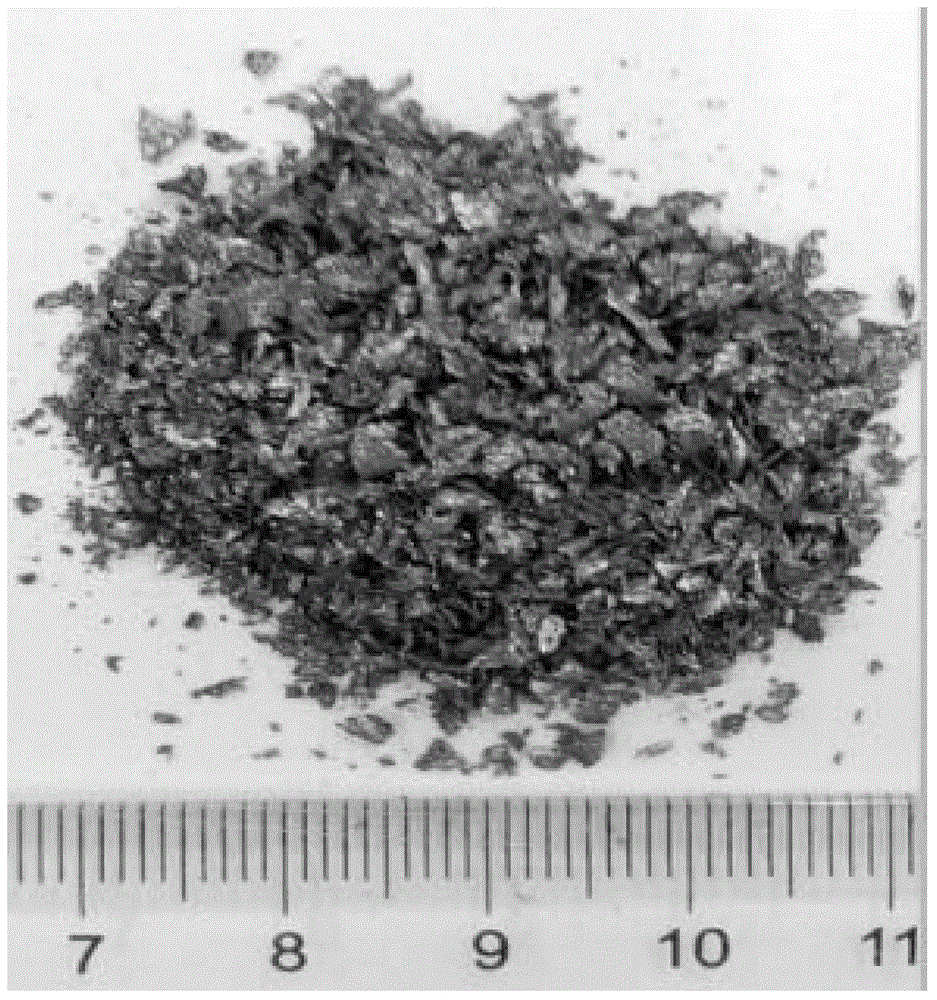

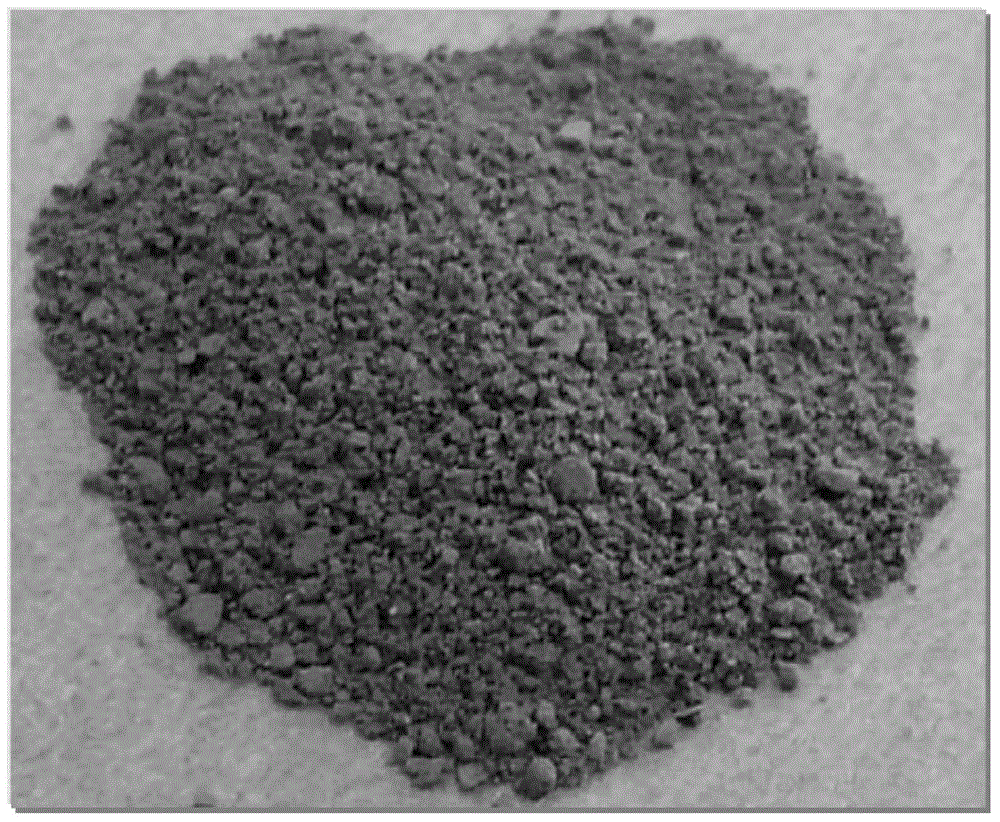

[0165] First, the aluminum-silicon alloy ingot (such as figure 1 ) crushed and ground into debris of 0.1mm to 100mm, then 20g of aluminum silicon alloy debris with a diameter of 0.1mm to 100mm (such as figure 2 ), slowly added to 270ml of 5% dilute hydrochloric acid solution to react, magnetically stirred evenly. After the mixed solution is fully reacted, the mixed solution is filtered and rinsed with deionized water and ethanol to remove AlCl 3 Porous silicon nanoparticles are obtained; then the porous silicon nanoparticles are added to a 5% mass ratio of hydrofluoric acid solution for cleaning, after the surface of the porous silicon nanoparticles or excess silicon oxide have been removed, filter and fully rinse with deionized water and ethanol , to collect porous nano-silicon with single composition and relatively uniform morphology, such as image 3 .

[0166] After porous nano-silicon is mixed with polyacrylonitrile, carry out ball milling (wet milling), ball milling ...

Embodiment 2

[0171] First, the aluminum-silicon alloy ingot (such as figure 1 ) crushed and ground into chips of 0.1 mm to 100 mm, 50 g of aluminum silicon alloy chips with a diameter of 0.1 mm to 100 mm were slowly added to 480 ml of 10% dilute hydrochloric acid solution for reaction, and magnetically stirred evenly. After the mixed solution is fully reacted, the mixed solution is filtered and rinsed with deionized water and ethanol to remove AlCl 3 Porous silicon nanoparticles are obtained; then the porous silicon nanoparticles are added to a 5% mass ratio of hydrofluoric acid solution for cleaning, after the surface of the porous silicon nanoparticles or excess silicon oxide have been removed, filter and fully rinse with deionized water and ethanol , Porous nano-silicon with single composition and relatively uniform morphology was collected.

[0172] After porous nano-silicon is mixed with polyacrylonitrile, ball milling (wet milling) is carried out. Ball milling equipment: Germany Lai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com