Liquid alkali-free accelerator and preparation and application thereof

A technology of quick-setting agent and liquid, which is applied in the field of engineering construction, can solve the problems of poor cement adaptability, etc., and achieve the effects of increased strength, good adaptability, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take 70kg of aluminum hydroxide and put it into the reaction kettle, then add 260kg of hydrofluoric acid solution with 20% mass content and stir (rotation speed 20-30 rpm) for about 20min, dissolve to a transparent solution, add 440kg of aluminum sulfate, and stir for 10-20min until complete Dissolve; add water 120kg.

[0041] Then add pH regulator NaOH solution (prepared by adding 10kg of NaOH and 80kg of water) to adjust the pH value to ≥ 2.0; add 12kg of triisopropanolamine, then slowly add 10kg of water glass, stabilizer, enhancer, and cosolvent, and stir until it becomes uniform The liquid is the liquid alkali-free accelerator. The distribution ratio of each component is shown in Table 1.

[0042] Let stand for 3 to 5 minutes, unload and pack.

Embodiment 2、3、4、5、6

[0044] The quick-setting agent preparation process of embodiment 2,3,4,5,6 is the same as embodiment 1, and the mass percent of each component is different. See Table 1 for details.

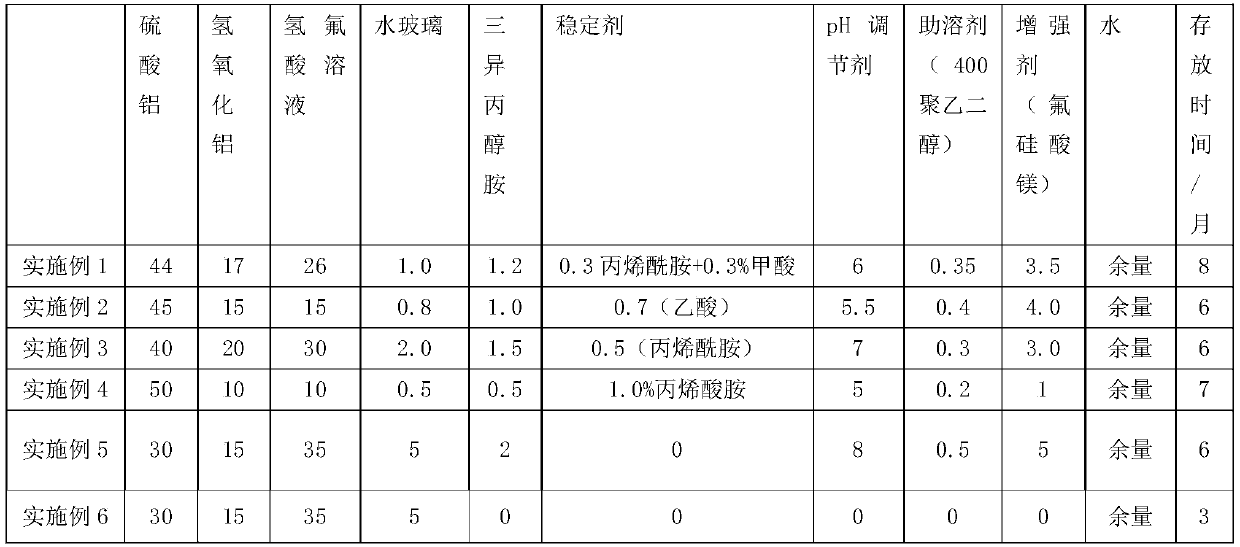

[0045]Table 1: Formula of embodiment 1-6 liquid alkali-free quick-setting agent

[0046]

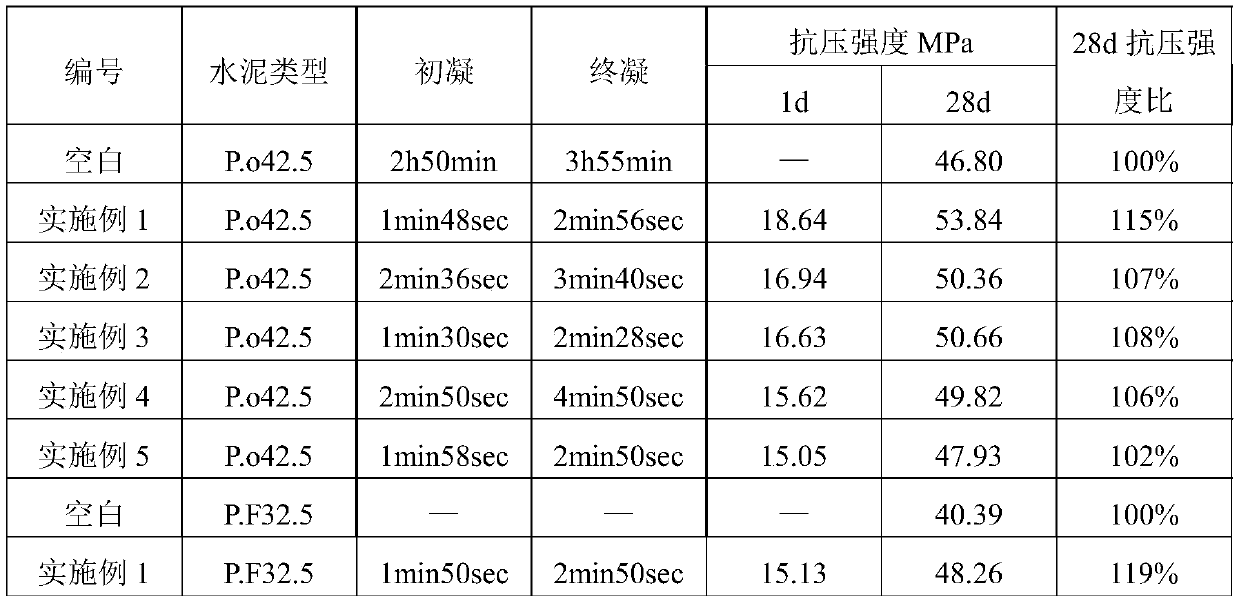

[0047] Stabilizers, enhancers, pH regulators, and co-solvents need to act synergistically within an appropriate range. Among them, the pH regulator is more preferably 7% or less. In the case where no stabilizer, enhancer, pH regulator, and co-solvent were added (Example 6), the product was stored for three months, and precipitation was observed. The following cement setting tests were performed only with the products of Examples 1-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com