Silicon cantilever sensor, preparation method and application thereof

A cantilever beam and sensor technology, applied in the field of micro-nano sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

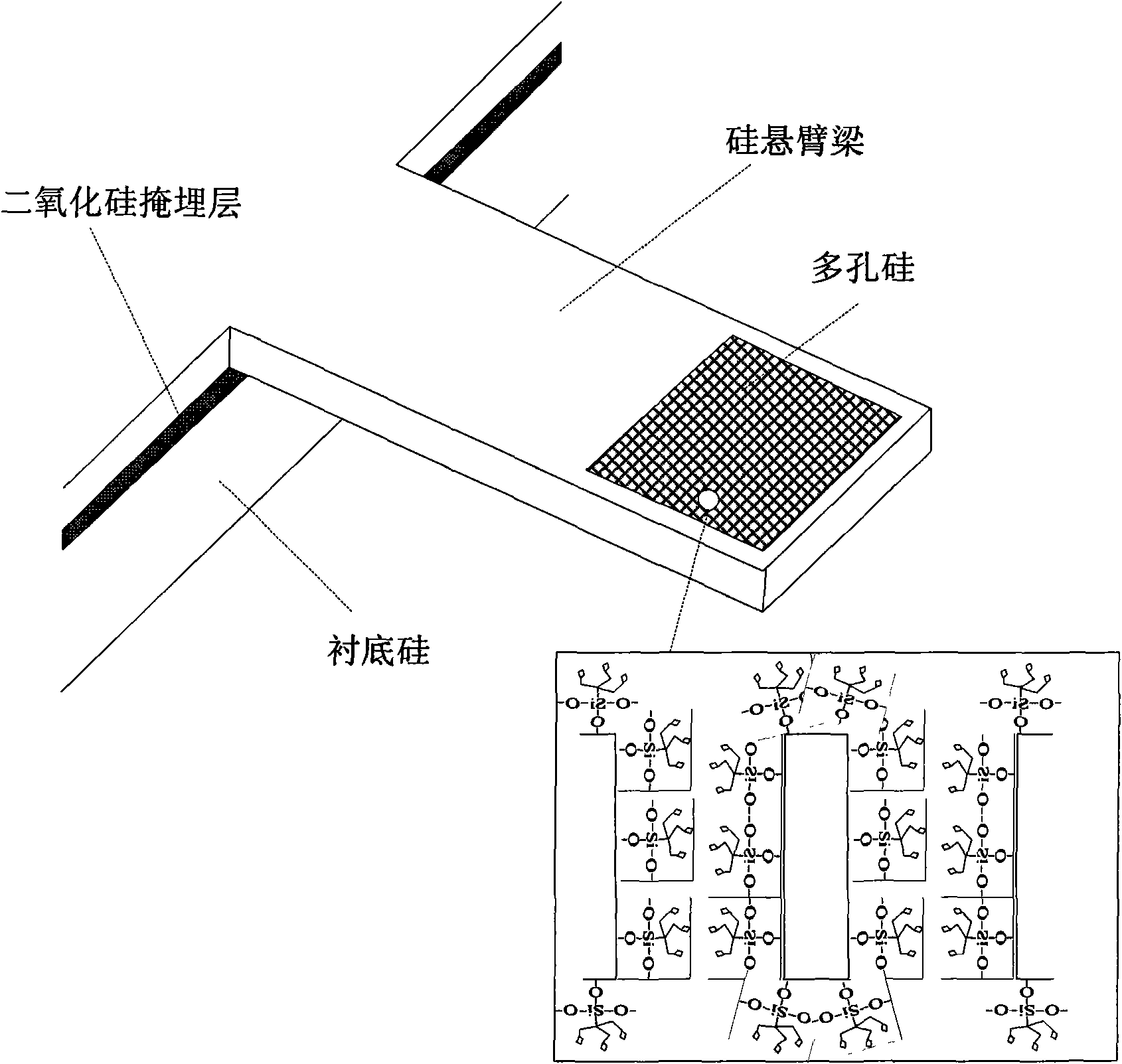

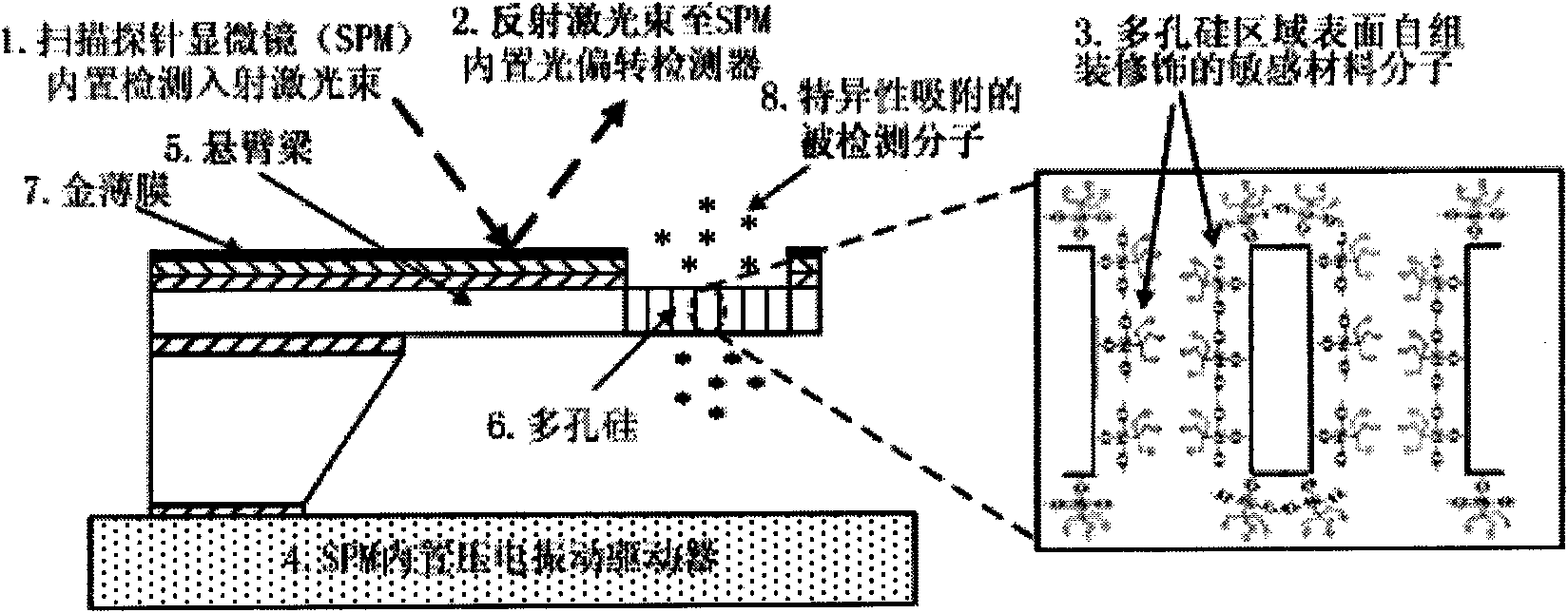

[0046] Explosive trinitrotoluene (TNT) chemical gas sensor

[0047] This implementation application takes the detection of explosive trinitrotoluene (TNT) gas as an example to describe the application of the present invention in chemical gas detection in detail.

[0048] Explosives Trinitrotoluene (TNT) is a commonly used explosive and is therefore an extremely hazardous hazard. Effective detection of TNT volatile gas will provide technical support for security checks and anti-terrorism in transportation hubs and important locations such as airports, stations, ports, and customs, and is of great significance to ensuring public safety.

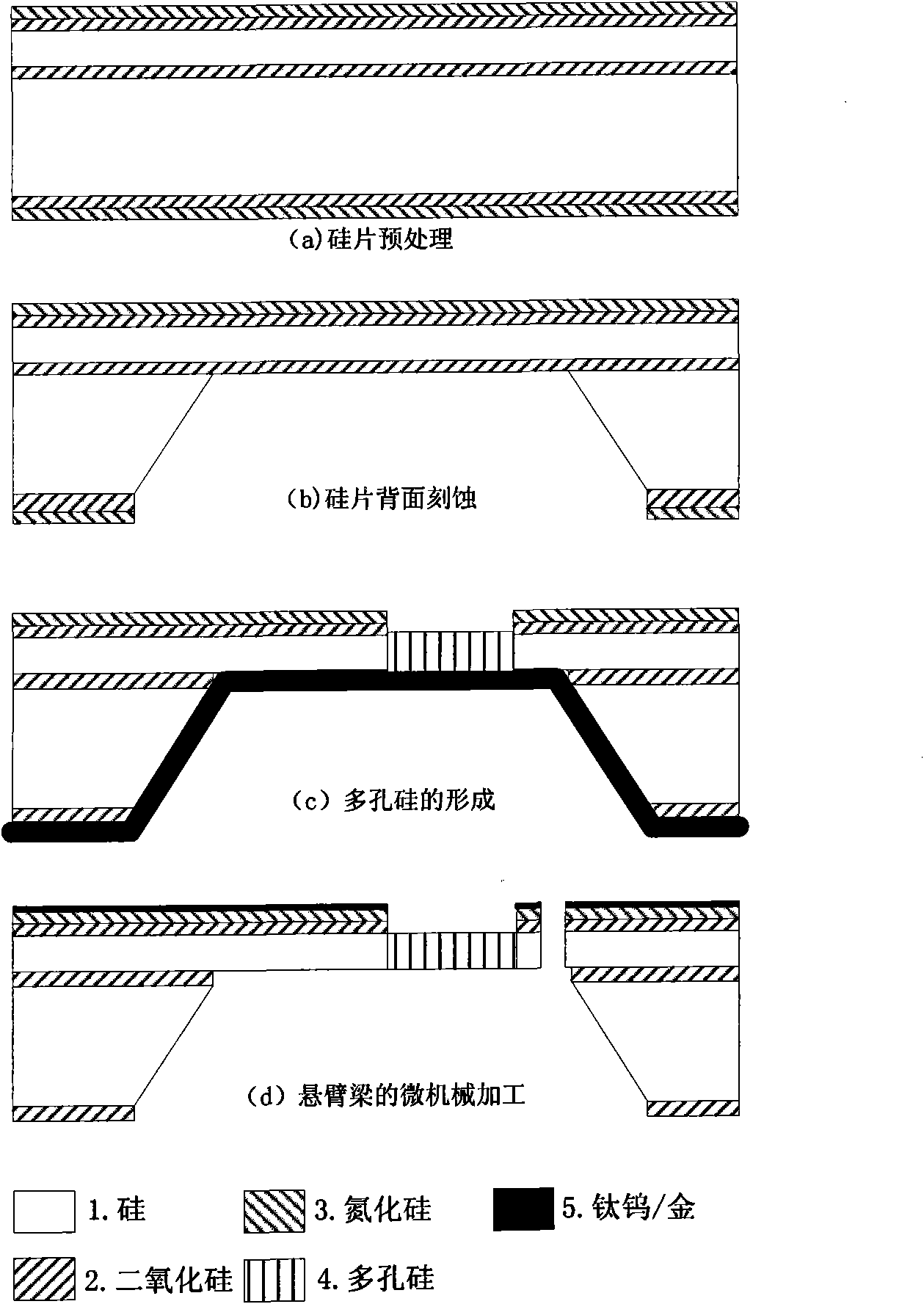

[0049] Fabrication of a 300μm×100μm×3μm porous silicon cantilever beam sensor, see attached figure 2 , the first resonance frequency of its bending mode is around 100kHz, and its specific preparation steps are as follows:

[0050] (a), wafer pretreatment

[0051] A double-sided polished SOI silicon wafer with n-type doped (100) crystal plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com