Negative plate and lithium ion battery

A technology of negative electrode and negative electrode, applied in the field of negative electrode and lithium ion battery, can solve the problem of poor cycle performance, achieve high liquid retention, ensure electronic conductivity, and good ionic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

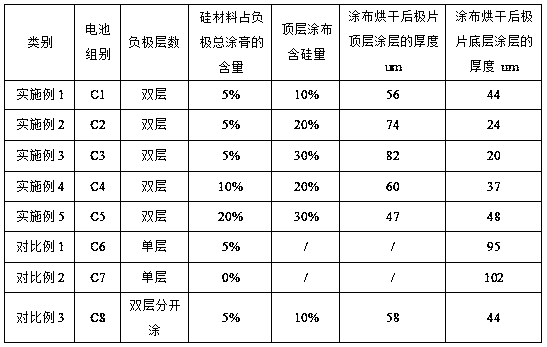

specific Embodiment approach 1

[0014] Embodiment 1: This embodiment describes a negative electrode sheet, including a negative electrode current collector and a film layer coated on the current collector. The film layer is divided into two layers, and the first film layer is close to the current collector. The underlying graphite coating of the fluid, the coating has the characteristics of large compaction, small expansion of the coating after charging, and poor liquid storage capacity; the second film layer is the top silicon-containing coating far away from the current collector, and the coating has High gram capacity, large coating expansion after charging, and strong liquid storage capacity; among them, the proportion of silicon material in the top silicon-containing coating is 5wt.% ~ 30wt.%; the silicon material in the negative electrode sheet accounts for 10% of the total active material weight of the negative electrode sheet 5%~20%; After coating and drying, the thickness of the bottom graphite coati...

specific Embodiment approach 2

[0015] Specific embodiment two: a kind of negative electrode sheet described in specific embodiment one, adopts double-mode coating head extrusion coating machine, two kinds of slurries are coated on the negative electrode current collector at the same time, on the same side of the negative electrode current collector After forming a double-layer paste structure, prepare a silicon-containing coating on the top layer, and a silicon-free pure graphite layer on the bottom double-layer coating negative electrode sheet; after coating one side of the current collector, repeat the other side according to the above way to coat.

specific Embodiment approach 3

[0016] Embodiment 3: In the negative electrode sheet described in Embodiment 1, the negative electrode current collector is one of homogeneous copper foil, porous copper foil and copper foil with carbon coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com