Lithium ion secondary battery polymer separation film corona processing method

A secondary battery, corona treatment technology, applied in battery pack parts, non-aqueous electrolyte batteries, electrolyte battery manufacturing and other directions, can solve the problem of unfavorable bonding, the interface between the separator and the electrode is not tightly combined, affecting the energy density and energy density of the battery. security and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

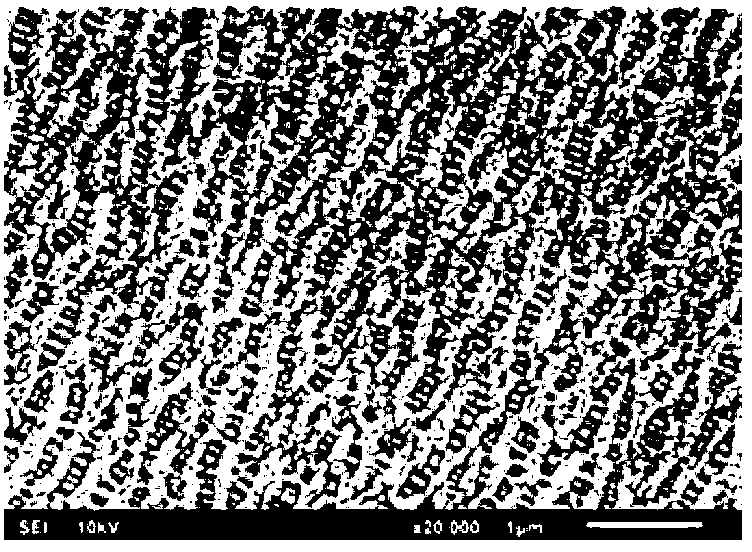

[0023] Corona treatment machine provides 50Hz, 5000V / m 2 AC voltage, using 20μm thick polyethylene lithium battery diaphragm material as the treatment sample, and passing through the corona treatment machine at a speed of 1m / min. Measure the temperature of the corona treatment equipment space as 25°C and the relative humidity as 20%. The output power of the corona treatment machine is controlled at 30%, and the single-sided corona discharge treatment is performed on the transmission diaphragm material. Surface appearance of polyethylene battery separator figure 1 As shown, the scanning electron microscope image is shown in figure 2 shown. The surface appearance of the diaphragm after corona treatment is as follows image 3 As shown, the scanning electron microscope image is shown in Figure 4 shown. The figure above shows that after 30% power corona discharge treatment, the surface of the separator occasionally has needle-like appearance, indicating that the corona outp...

Embodiment 2

[0025] Corona treatment machine provides environment and corona treatment time with described in embodiment 1. The corona-treated separators were placed in different environments, and the relevant wettability tests were carried out. The contact angle of polyethylene separator without corona discharge treatment is 69 degrees, after 5%, 10%, 20%, 30% and 35% power corona discharge treatment, the contact angle becomes 58 degrees, 39 degrees, 32 degrees, 29 degrees and 28 degrees. It shows that the 20μm thick polyethylene lithium battery separator undergoes corona discharge treatment, the contact angle of the separator becomes smaller, the surface tension increases, and the wettability is enhanced. The output power of corona discharge between 10 and 30% has a good effect on the experimental separator Effect. After the separator was placed at room temperature for 5 days, the contact angle was measured again. The contact angle of the untreated separator was 73 degrees, and the con...

Embodiment 3

[0027] Corona treatment machine provides environment and corona treatment time with described in embodiment 1. The corona discharge treated diaphragm was soaked in electrolyte, and its liquid retention was tested after standing for different times at room temperature. After 5%, 10%, 20%, 30%, 35% output power corona treatment of the diaphragm, its liquid retention performance has been improved to a certain extent, and the liquid retention capacity of the corona treated diaphragm battery is increased by about 0.01 compared with the untreated diaphragm battery. g, 0.08g, 0.1g, 0.12g, 0.12g. By comparing the liquid retention capacity of the diaphragm battery treated with corona with different powers, the corona discharge power between 10% and 30% will have a significant impact. At room temperature, the corona-treated separator was soaked in the electrolyte at 10-30% power and placed for 15 days. The separator still had good liquid retention, indicating that the corona effect was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com