Multilayer compound wick material and its production technology

A production process and a liquid-absorbent core technology, which are applied in the field of multi-layer composite liquid-absorbent core material and its production process, can solve the problems of poor dimensional stability, short production rate of process flow, easy pilling of non-woven fabrics, etc. Increase strength and toughness, reduce fault phenomenon, reduce the effect of reverse osmosis water phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

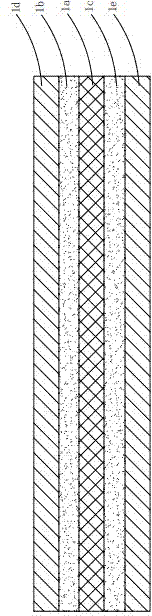

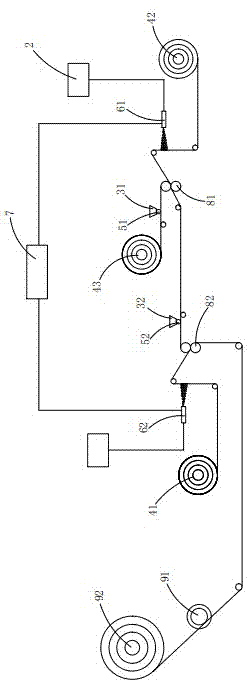

[0026] Figure 1 to Figure 2 Shown is the structural representation of the present invention,

[0027] The reference signs are: non-woven fabric layer 1a, upper water-absorbing resin layer 1b, lower water-absorbing resin layer 1c, upper water-absorbing paper layer 1d, lower water-absorbing paper layer 1e, hot melt box 2, first water-absorbing resin hopper 31, second water-absorbing resin layer Two absorbent resin hoppers 32, upper absorbent paper roll 41, lower absorbent paper roll 42, fluffy non-woven fabric roll 43, first resin transfer roll 51, second resin transfer roll 52, first hot melt glue gun 61, second Hot melt glue gun 62 , compressed air bag 7 , first composite pressure roller 81 , second composite pressure roller 82 , slitting knife 91 , coiler 92 .

[0028] like Figure 1 to Figure 2 As shown, the present invention's

[0029...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com