Band bundling machine

A technology of a strapping machine and a strapping belt, which is applied in the field of strapping machines, can solve the problems of difficulty in placing the objects to be bundled, reduction in the efficiency of the strapping work, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention are described with reference to the drawings.

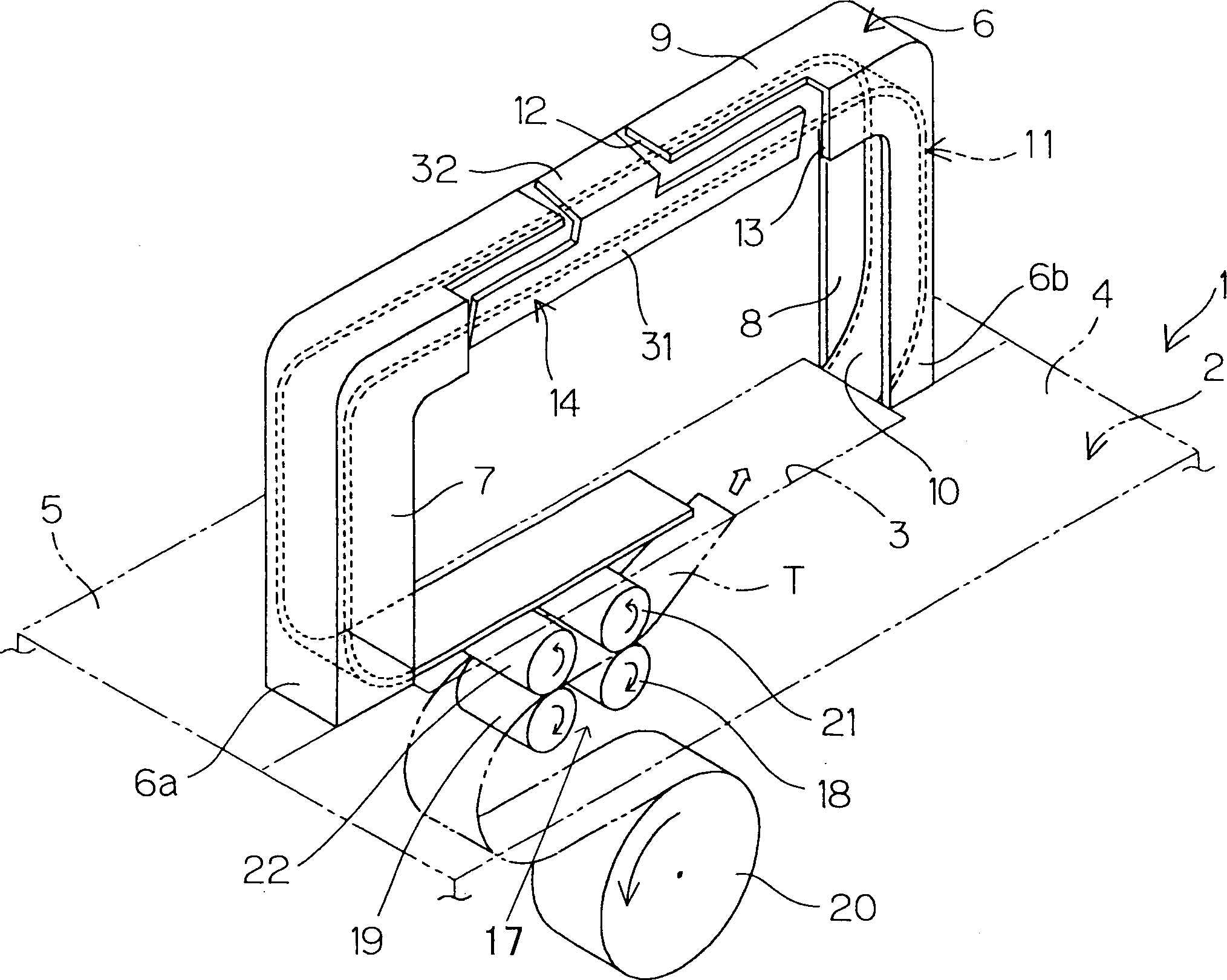

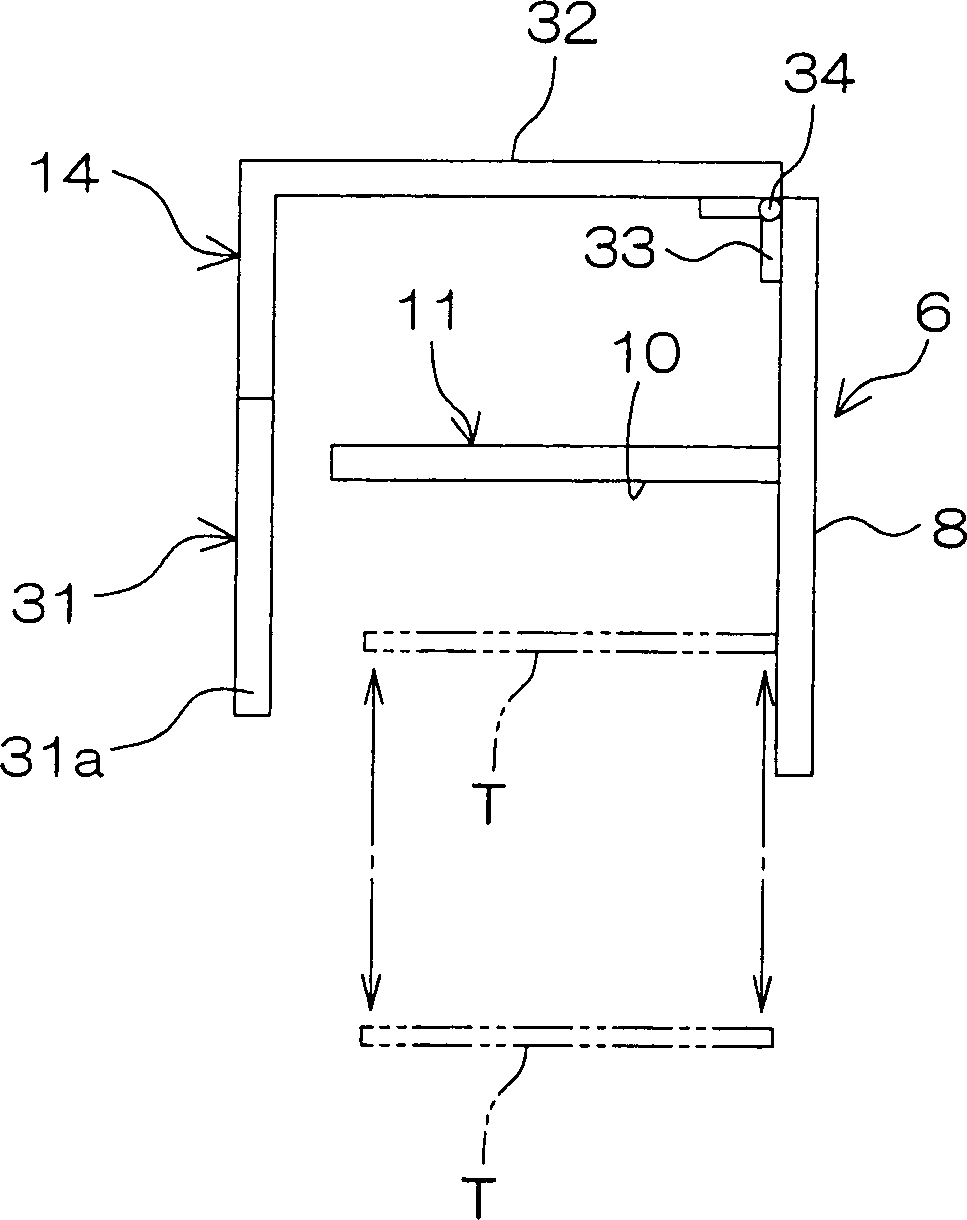

[0015] figure 1 The main part of the strapping machine which is one embodiment of this invention is shown. Referring to this figure, the top of the strapping machine main body 1 is formed by a workbench 2 for placing objects to be bundled. This workbench 2 is divided into a front workbench 4 and a rear workbench 5 with a passing groove 3 serving as a passage for the binding band interposed therebetween. At both ends of the passing groove 3 and above the table 2, leg portions 6a, 6b on which an arched guide frame 6 is arranged are fixed. The guide frame 6 is formed in a shape having a pair of flanges 7, 8 and a web 9 connecting the flanges 7, 8 with a U-shaped cross section (so-called groove shape). The front side wall and the rear side wall of the guide channel 10 are formed by the above pair of flanges 7 and 8 .

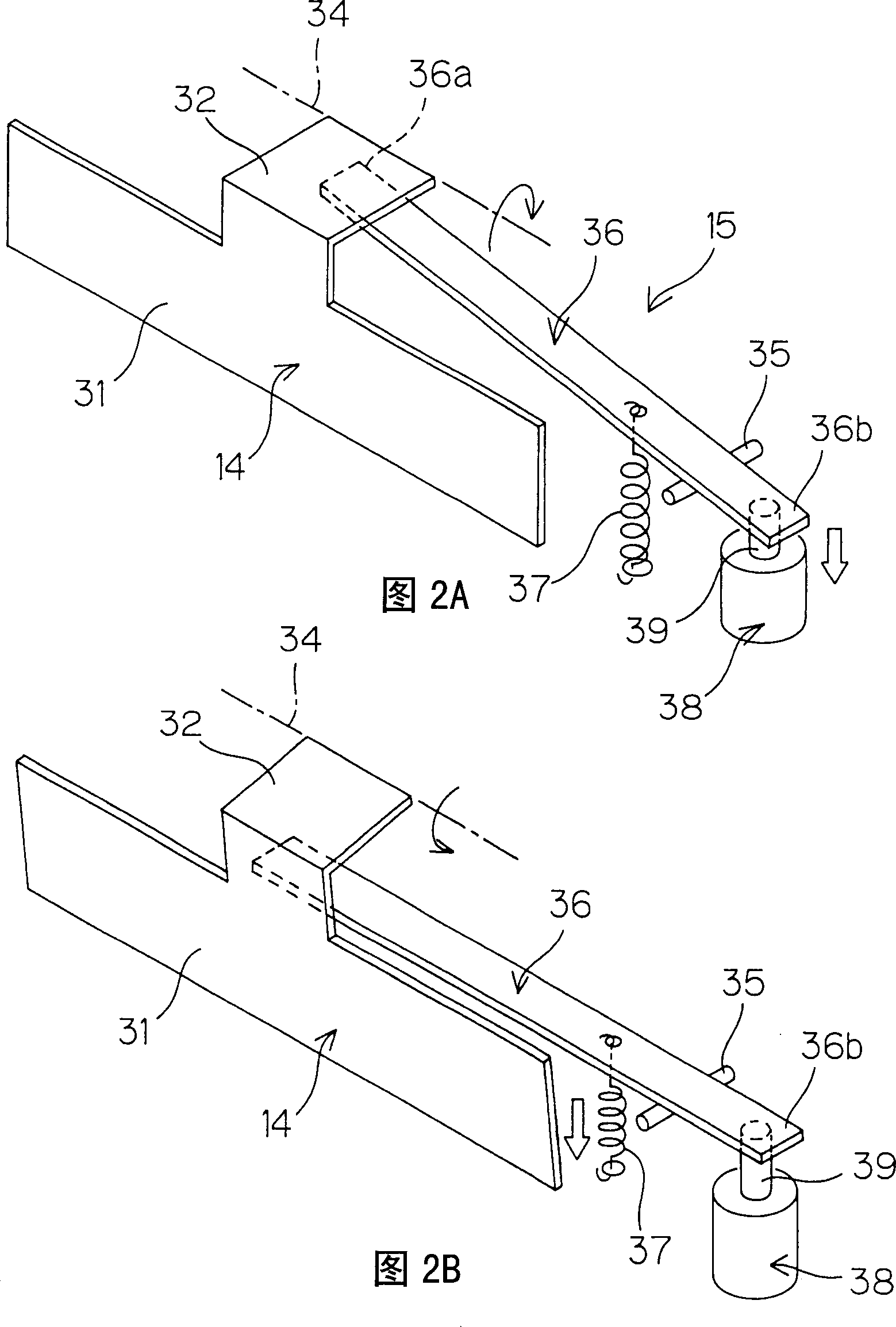

[0016] In addition, inside the guide frame 6, a guide memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com