Book binding machine and method for operating same

A technology for a binding machine and a glue binding machine, which is applied to book binding and flattening machines, adhesives for binding, binding and other directions, and can solve problems such as reduced productivity, problems, and the inability of the binding machine to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

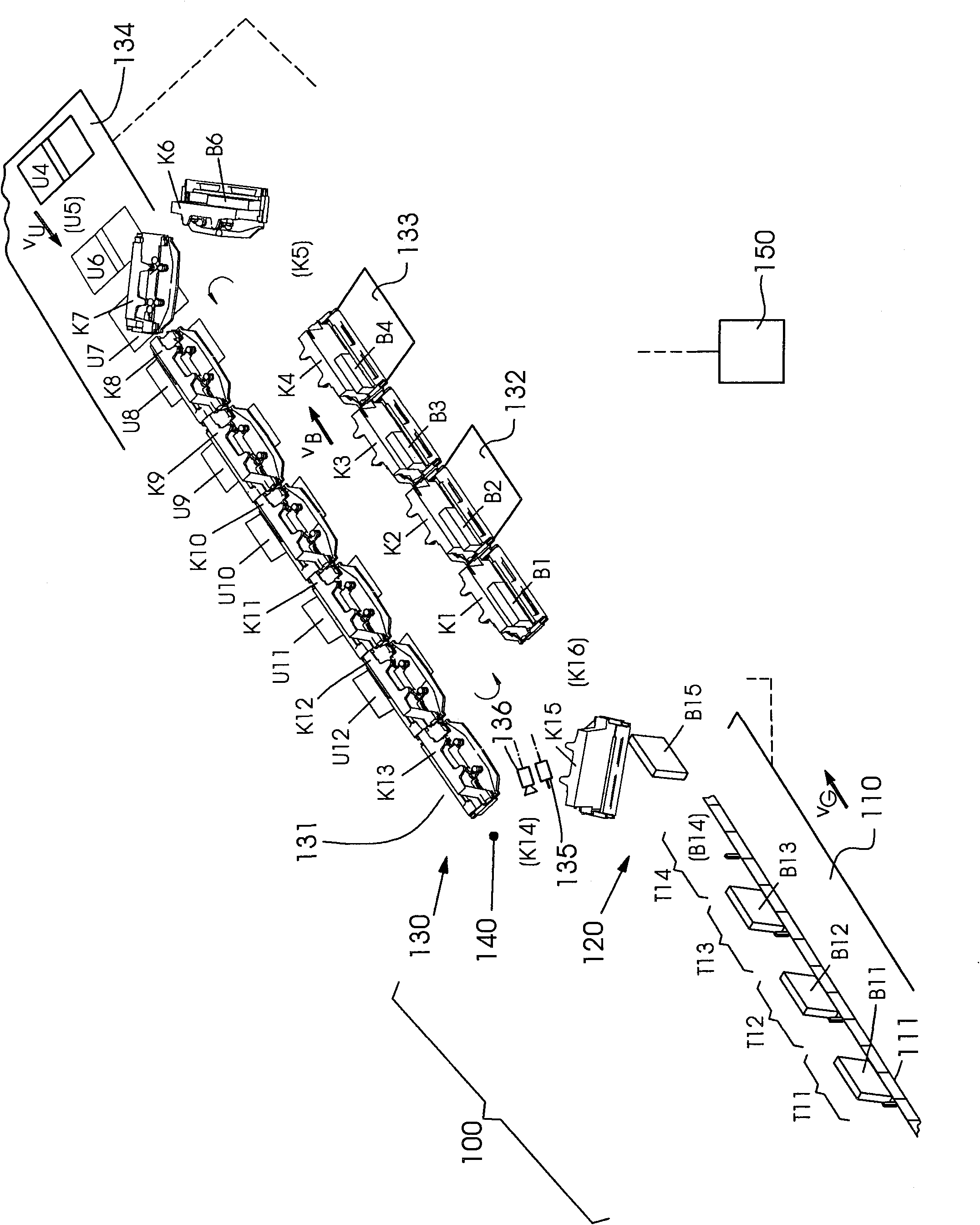

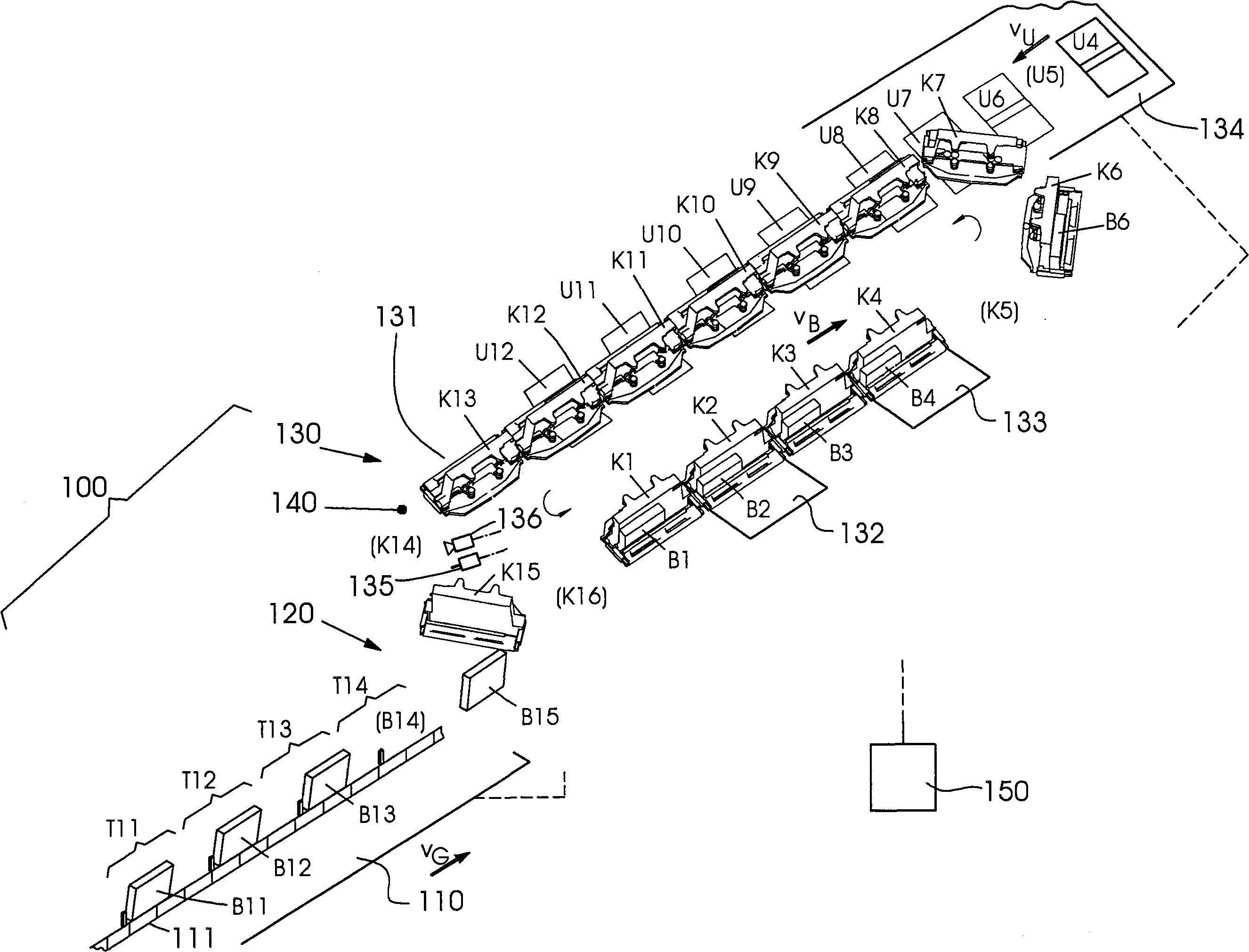

[0022] figure 1 A bookbinding machine 100 is shown having a collating machine 110, a transfer unit 120, a perfect binder 130 and a cooling section 140 with a cutting station (not shown).

[0023] In the collating machine 1010 , individual signatures are deposited from the repeater into the transport sections T11 , T12 , T13 , T14 of a collecting device 111 and are thus collated into book blocks B11 , B12 , B13 . For greater clarity, the repeater is not shown. The book blocks B are moved by the collating machine 110 in the conveying direction vG and are fed by a transfer device 120 in the conveying direction to the perfect binder 130 . The book block B is transported through the perfect binder 130 in the transport direction vB by a book block transport system formed by driven grippers K which grab the book block B and hold it in an unattended position. run around on the rails shown. The book blocks B are conveyed to a first processing station, the spine processing station 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com