System, control method, recording medium and program for an image forming apparatus

An image and controller technology, which is applied to the electrical recording process using charge graphics, equipment for the electrical recording process using charge graphics, and electrical recording technology, which can solve the problems of space occupation and cost, which are not easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

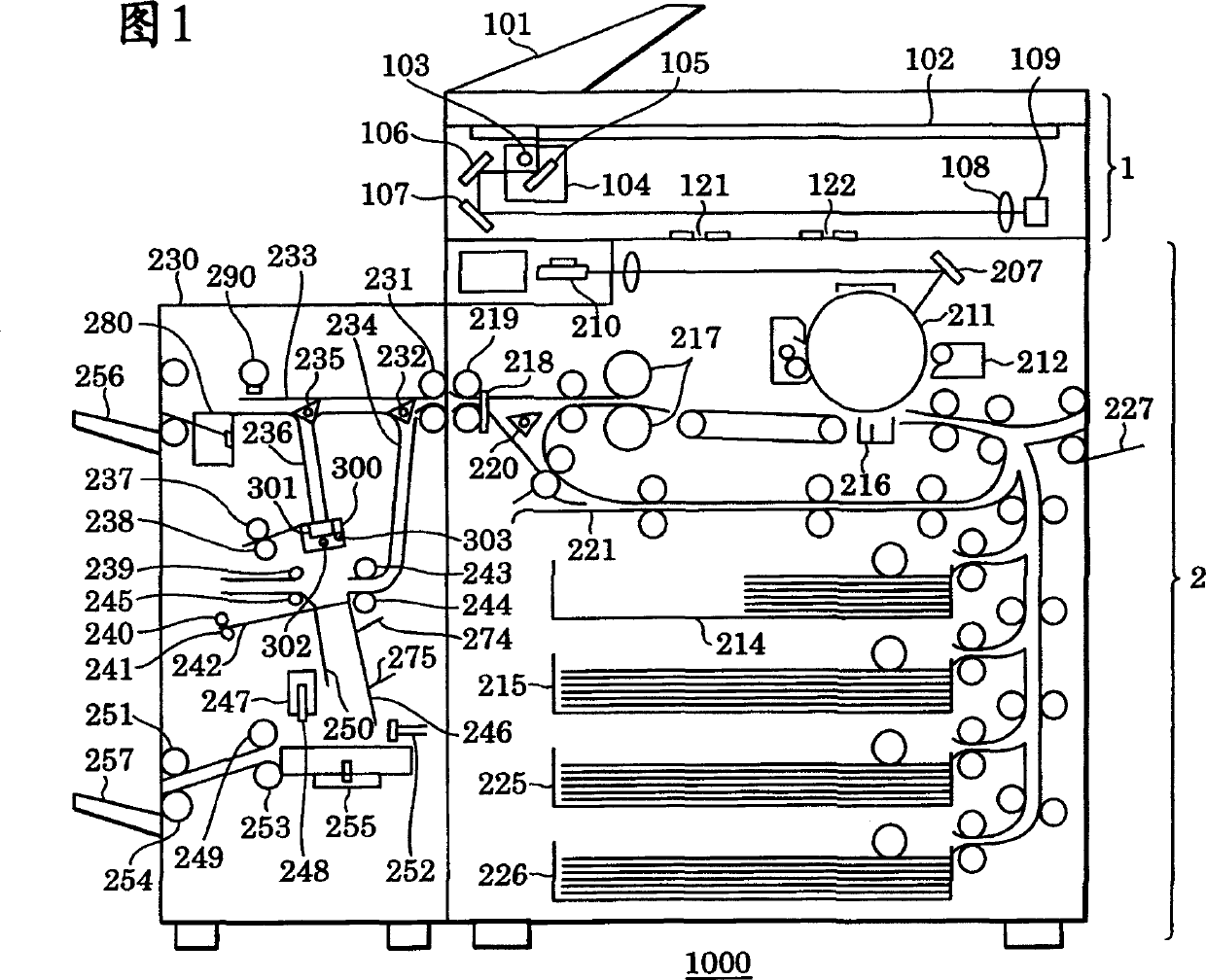

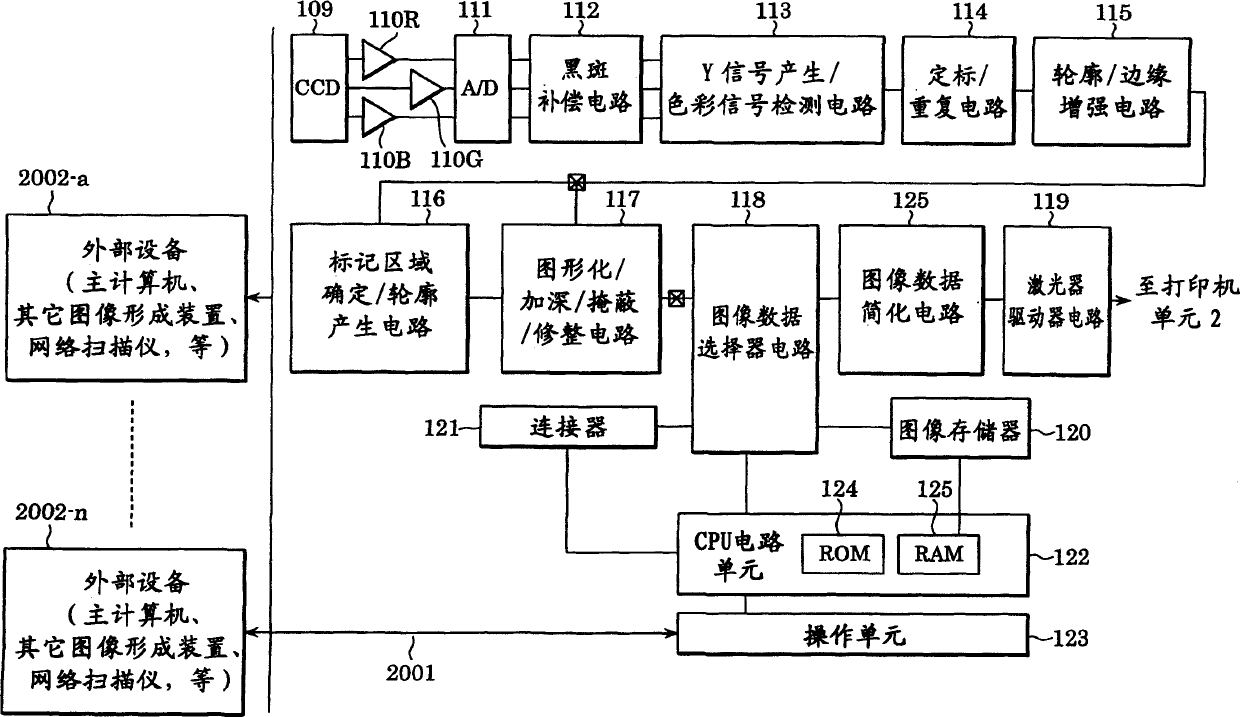

[0067] 1 is a sectional view showing the structure of a photocopier (digital multifunction device) that can be applied to an image forming apparatus (image forming system) according to a first embodiment of the present invention.

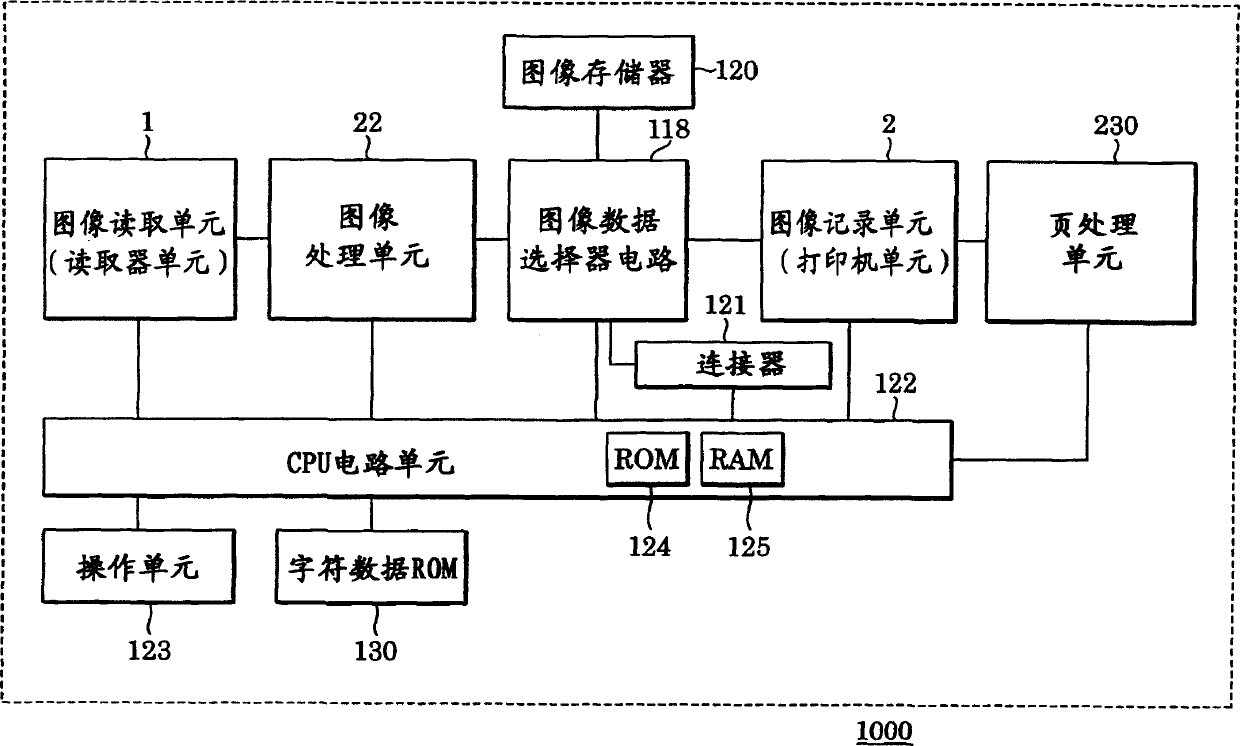

[0068] As shown in FIG. 1 , an image forming apparatus (also referred to as “image forming system”) 1000 according to the present invention has a reader unit 1 and a printer unit 2 . As a tool for performing various types of page processing (for example, binder processing, pad binding processing, finishing processing, staple processing, punch processing, sheet shifting processing, etc.) ), the system 1000 also has a binding unit 230 . The following is a description of the structure and action of the reader unit 1 . The structures and actions of the printer unit 2 and the binding unit (also referred to as "sheet processing device") 230 will be described later.

[0069] Note that, with image forming system 1000 , each of units such as reader unit 1 ...

example 1

[0648] Assume that the user sets 50 sheets of an A4-size double-sided original document on the original document feeding device 101, sets A-4 size printed sheets on the cassette 214, and sets a desired size printed sheet on the manual feed tray 227 ( In this case, 297 mm x 424 mm, which corresponds to a printed page of A4 size and a spine width of 4 mm). Then, once the user sets the case binding according to the operation flow shown in FIGS. Image data is read from both sides of the 50-page original document (S9-2). That is, a total of 100 faces of original document data are read out.

[0649] Next, the flow goes to step S9-2, where, based on the fact that the 100-sided original document data has been read out, it is determined that 50 printed pages are required for double-sided printing. That is, the system determines that the number of printed pages is "50". Note that the number of printed pages is determined based on print settings such as single-sided printing, 2-in-1 p...

example 2

[0652] Next, Example 2 will be described. In Example 2, it is assumed that the user sets five A4-size double-sided original documents on the original document feeding device 101, A4-size printed pages on the cassette 214, and a desired size on the manual feed tray 227. Printed pages (in this case, 297 mm x 424 mm, which correspond to a pair of A4 size printed pages and have a spine width of 4 mm).

[0653] Once the user sets the case binding according to the operation flow shown in FIGS. 6A to 7D and presses the start key 4-241, the flow goes to step S9-1, where the processing starts so that the original document is fed from the original document feeding device 101. , and read image data from both sides of the 5-page original document. That is, the original document data of 10 sides in total are read out. The flow goes to step S9-2, and since the original document data is 10 sides, it is determined that there are 5 pages in double-sided printing, so the number of printed pag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com