Automatic C-shaped-arm bearing laminating device

A technology for bonding devices and bearings, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of laborious sliding, unsmooth sliding, high precision of bearing seat processing and installation, and increase the sliding area , Easy assembly, smooth installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

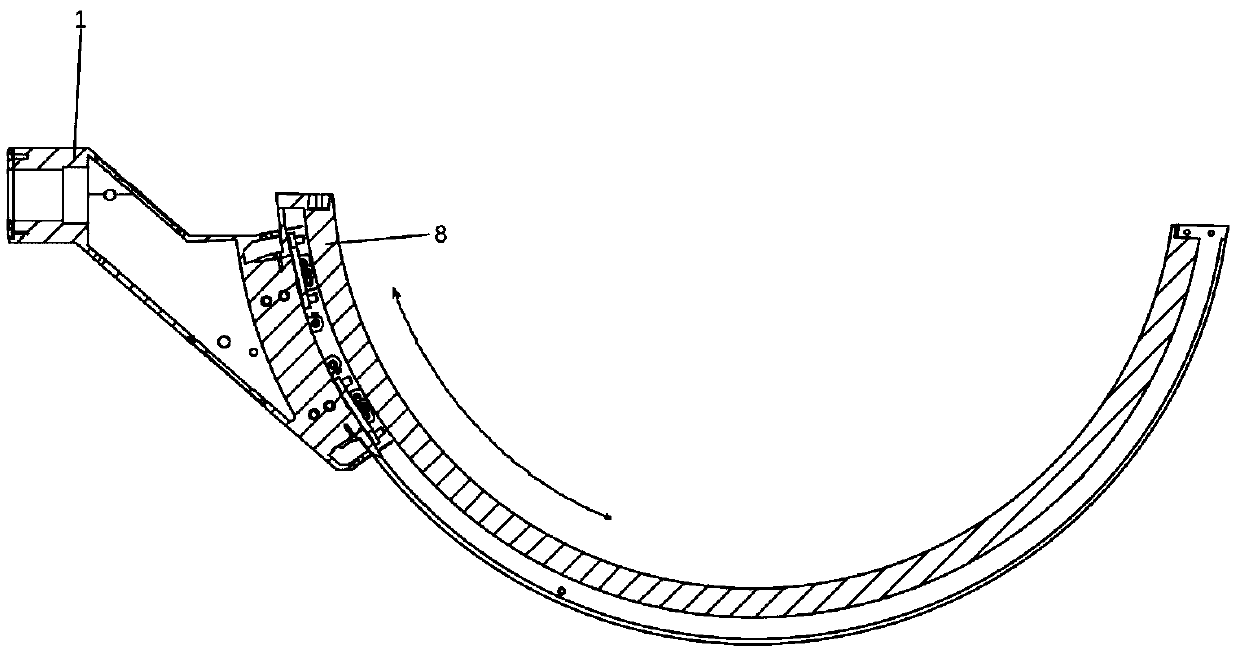

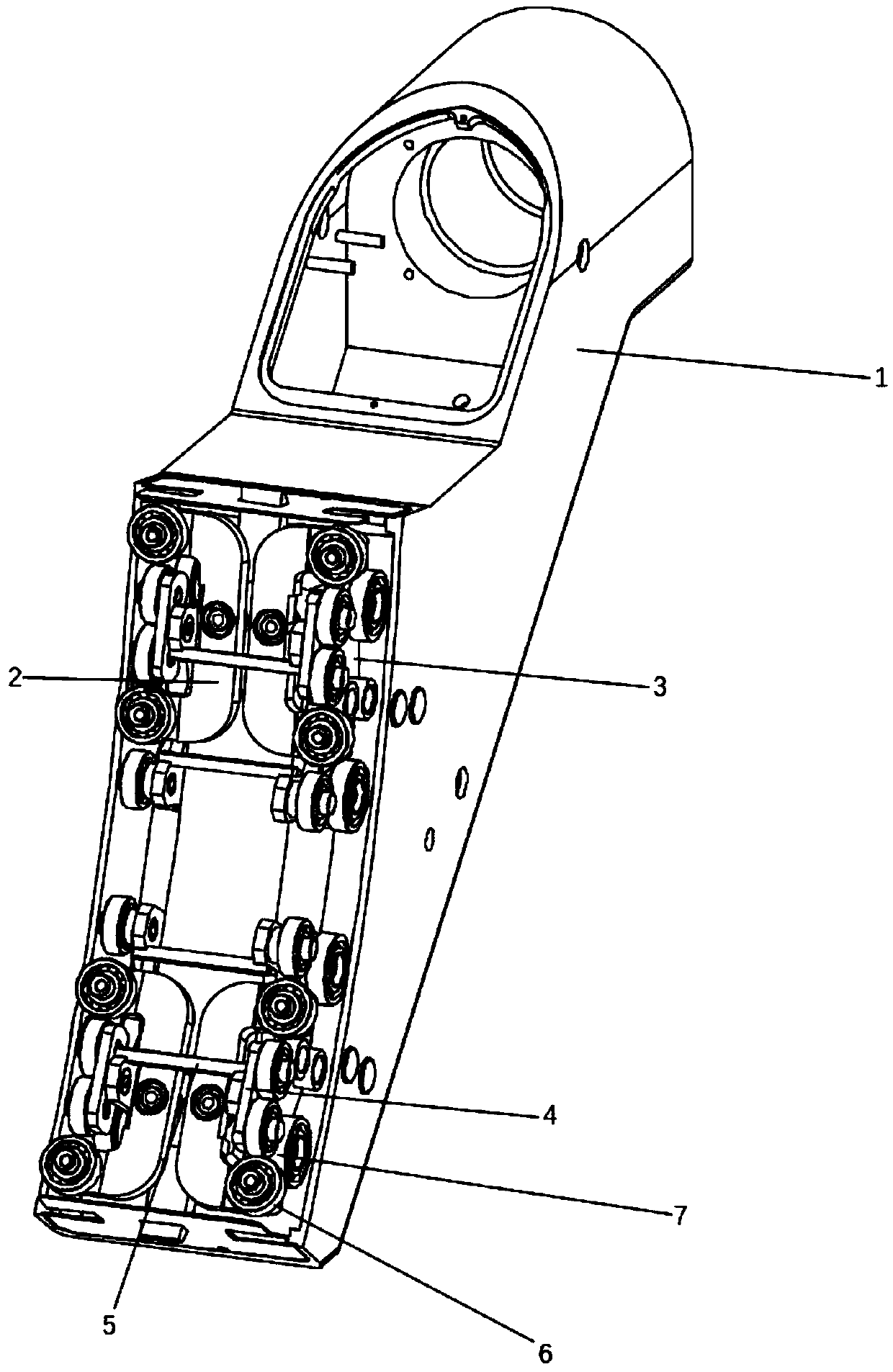

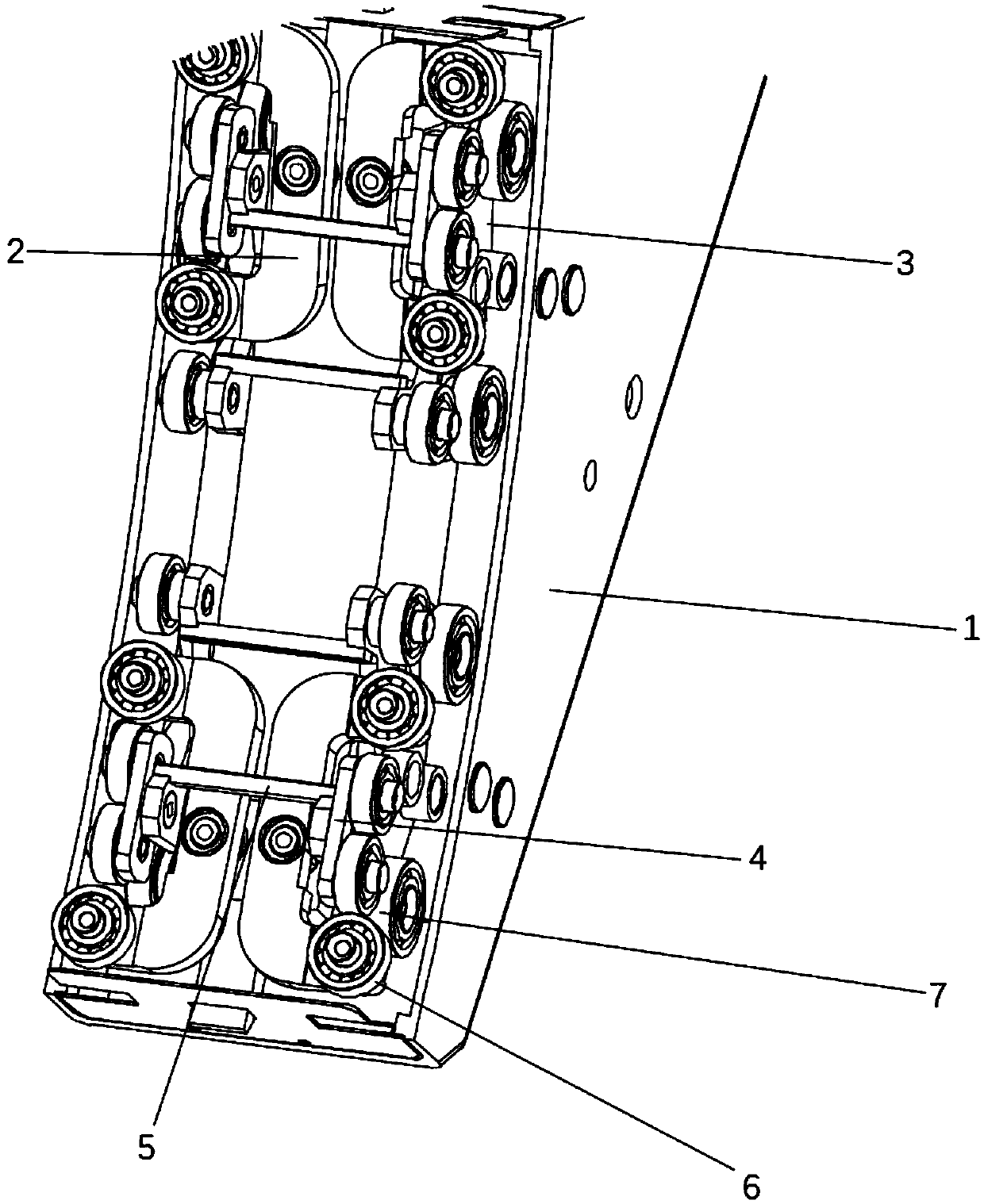

[0023] Such as Figure 1-3 As shown, the present invention provides a C-arm bearing automatic fitting device, including a straight arm 1 and a C arm 8, wherein the straight arm 1 is connected to the C arm 8; the straight arm 1 is connected to the C arm 8 in a non- Fixed connection; several sets of straight arm upper roller rods 2 are installed on the bottom of the straight arm 1, wherein the outer sides of the straight arm upper roller rods 2 are equipped with straight arm lower roller rods 3; the inner sides of the straight arm lower roller rods 3 are all installed There is a roller bar 4 in the straight arm; the first deep groove ball bearing 6 is installed on the outer side of the roller bar 4 in the straight arm. Further, a second deep groove ball bearing 7 is installed on one side of the first deep groove ball bearing 6, wherein the relative angle between the first deep groove ball bearing 6 and the second deep groove ball bearing 7 is 90 degrees.

[0024] Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com