Multifunctional steel plate polishing machine

A polishing machine and multi-functional technology, applied in the field of polishing machines, can solve the problems of time-consuming and laborious clamping of workpieces, low work efficiency, low positioning accuracy, etc., and achieve the effects of high qualification rate, simple structure and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

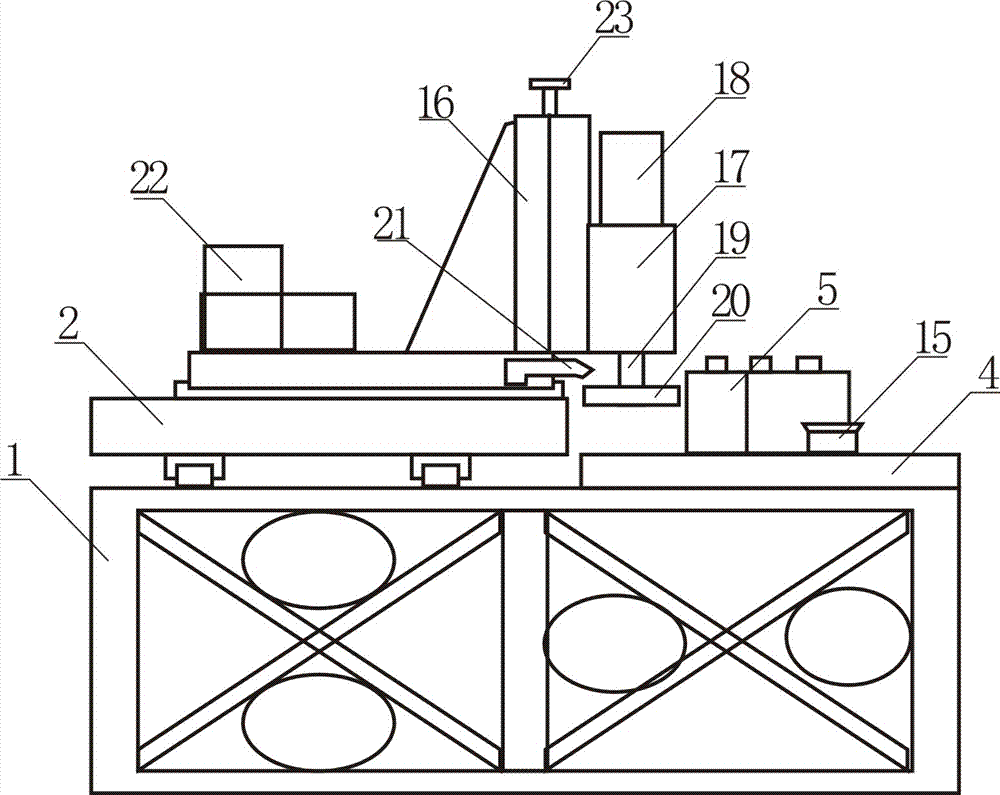

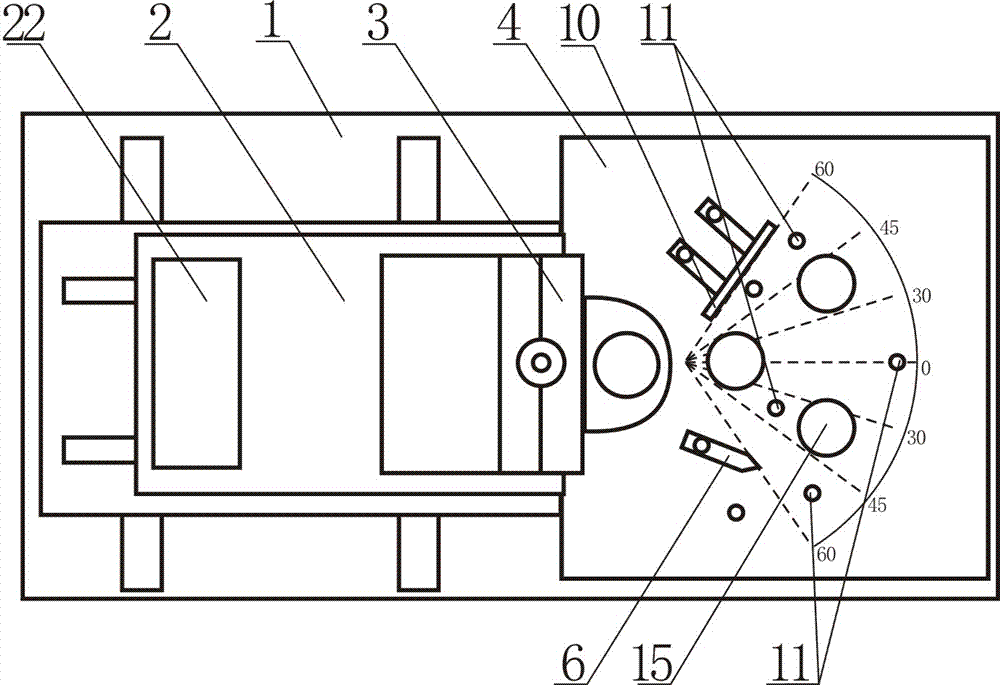

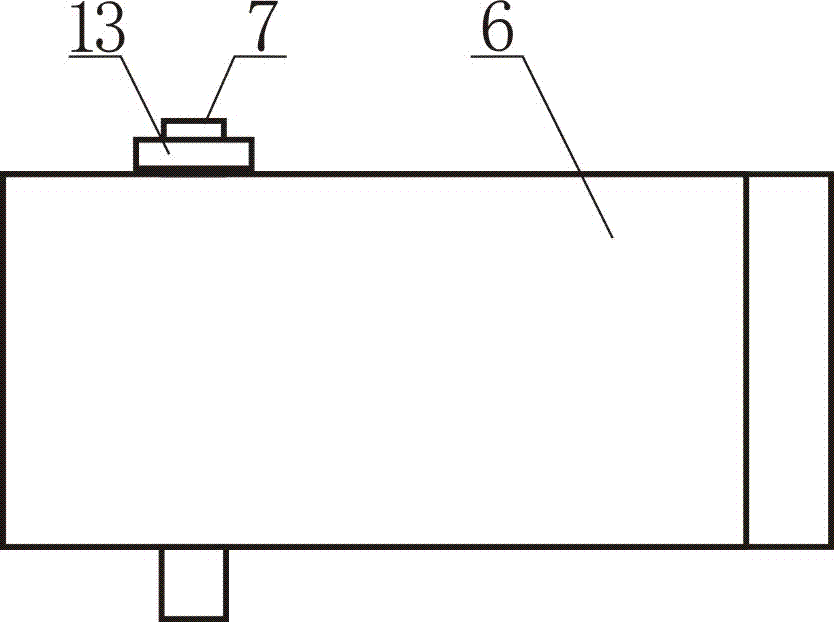

[0015] Such as figure 1 , 2 , 3, 4, 5, and 6, the multifunctional steel plate polishing machine includes an organic base 1, a translational polishing table 2 and a polishing mechanism 3, the translational polishing table 2 is arranged on the machine base 1, and the polishing mechanism 3 is arranged on the translational polishing table On the base 1 and on one side of the translational polishing table 2, an angle scale plate 4 and a polishing positioning fixture 5 are provided. The angle scale plate 4 is provided with a plurality of installation holes 11, and the plurality of installation holes 11 are distributed On the plate surface of the angle scale plate 4. The polishing positioning fixture 5 is mainly composed of a limit rod 6, a fixed seat 7, a connecting rod 8, two clamping rods 9 and a limit plate 10, and the fixed seat 7 is inserted into the mounting hole on the surface of the angle scale plate 4 In 11, the arm surface of the limit rod 6 is provided with an elongated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com