Mechanical assembly drum with attaching and compacting functions

A technology of forming drums and machinery, which can be applied to home appliances, other home appliances, tires, etc., can solve problems such as low work efficiency, poor tire quality, and large space occupation, and achieve high production efficiency and high tire quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

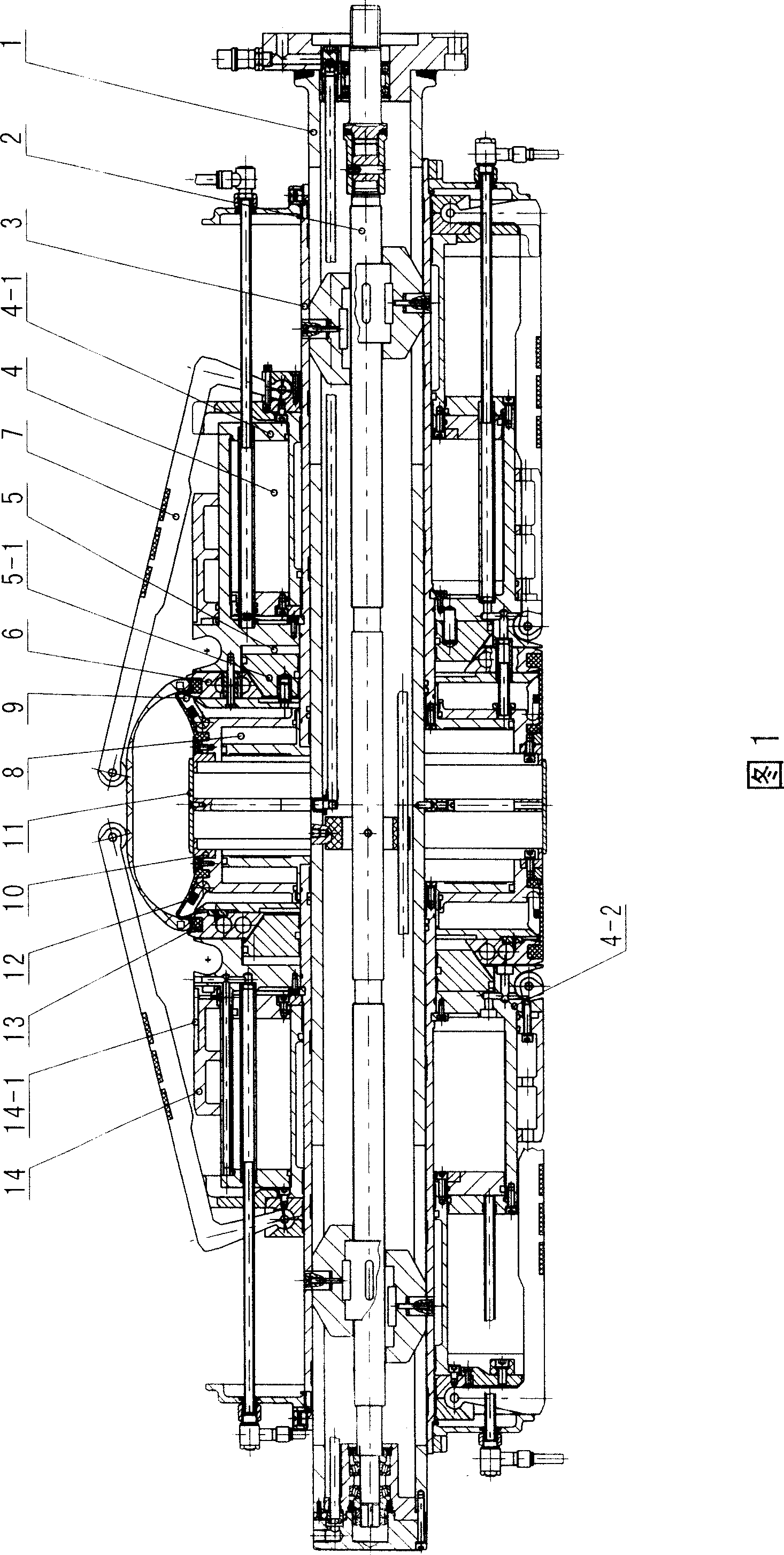

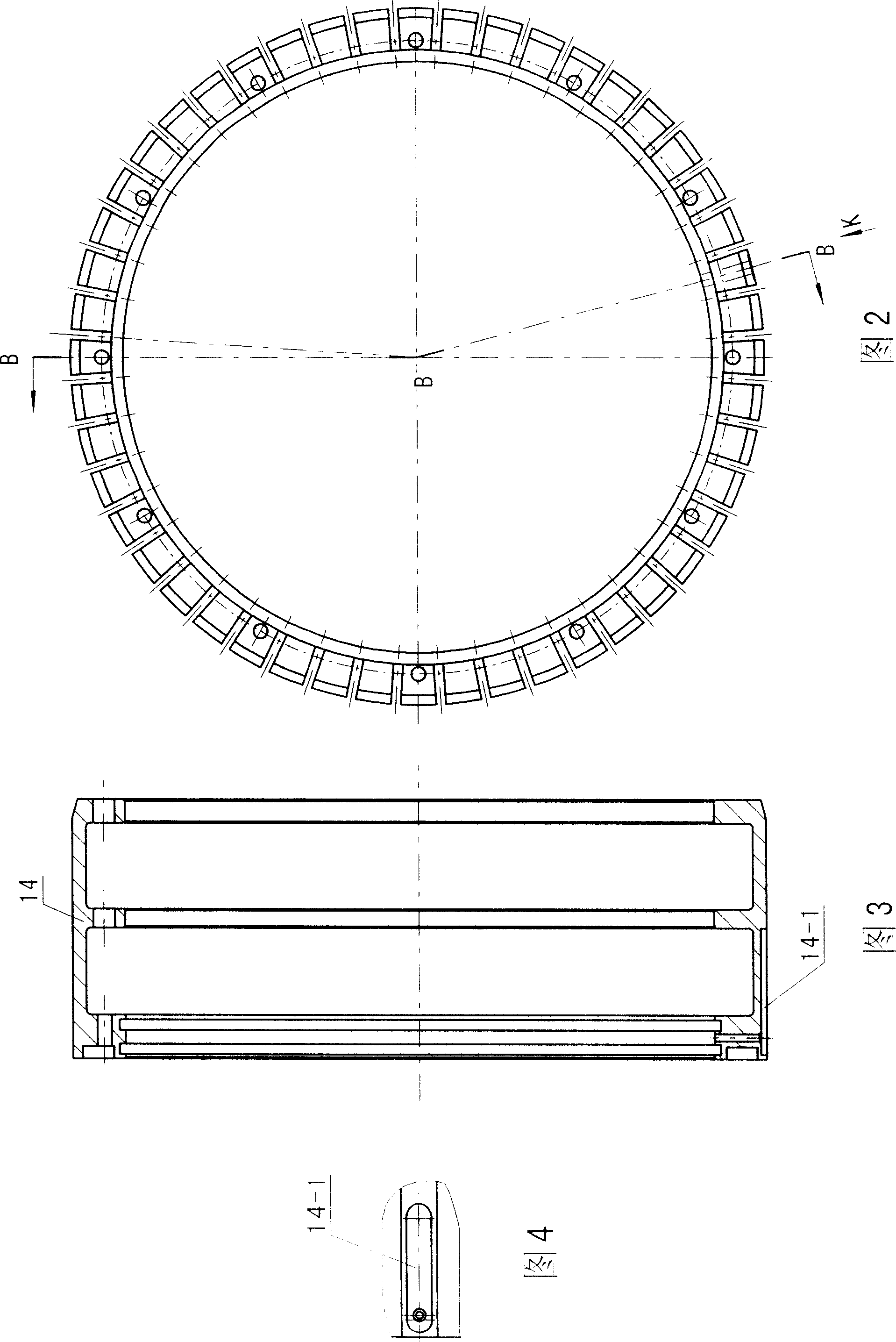

[0015] Please refer to Fig. 1, a mechanical forming drum with the function of bonding and compacting according to the present invention is a radial tire one-time forming drum that adopts mechanical turn-up, and can be found in the invention patent of an automatic turn-up and rolling mechanical forming drum, patent No. ZL03102556.0, which is the same as the invention patent, the invention includes a gas circuit system, a hollow main shaft 1 connected to the main box, and a screw 2 with left and right helical threads. The screw 2 is located in the hollow main shaft 1, and the left and right structures are symmetrical The mechanical turn-up side drum is set outside the hollow main shaft 1, wherein each side drum includes a main shaft sleeve 3 set on the hollow main shaft 1, and a turn-up cylinder 4 and a fan-shaped block cylinder 5 are adjacently set on the main shaft sleeve 3. Group fan-shaped block 6 is installed on the piston 5-1 of fan-shaped block cylinder, seal ring 13 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com