Tensioner with increased damping and arm on base cup configuration

一种张紧器、杯状件的技术,应用在车辆部件、摩擦减振器、机器/发动机等方向,能够解决带张力丧失、臂不能充分地跟随带、昂贵张紧器等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

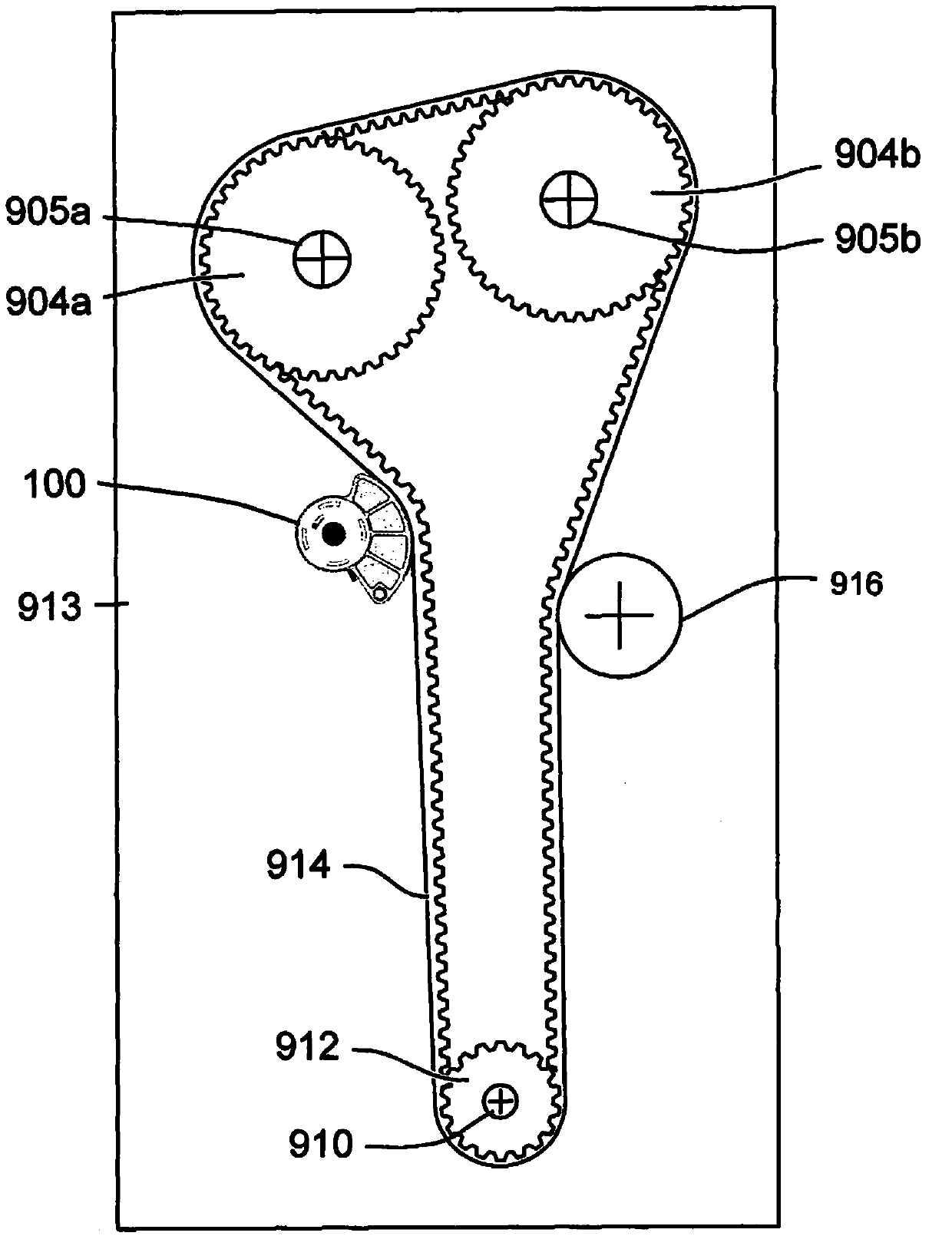

[0023] refer to figure 1 , which shows a crankshaft 910 of an engine 913 of a vehicle (not shown). It should be noted that the engine 913 is shown as a simple rectangle for illustrative purposes. It should be understood that the motor 913 may have any suitable shape. The vehicle may be any suitable vehicle, such as an automobile, truck, van, minivan, bus, sport utility vehicle, military vehicle, boat, or any other suitable vehicle. Timing belt 914 is shown extending between pulley 912 on crankshaft 910 of engine 913 and a pair of pulleys 904a and 904b on camshaft 905a and camshaft 905b to transfer rotational power from crankshaft 910 to the camshafts Shafts 905a and 905b.

[0024] For the implementation in which the timing belt is submerged in an oil sump (referred to as a belt in oil arrangement), the tensioner 100 is shown mounted to the engine 913 between the crankshaft 910 and the camshaft 905a. Tensioner 100 is used to maintain tension in timing belt 914 . An idler g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com