Method and apparatus for producing board and a board product

A product and cardboard technology, applied in paper/cardboard layered products, layered products, chemical instruments and methods, etc., can solve the problems of high investment cost, clumsy, expensive corrugated cardboard production lines, etc., to achieve high production cost-effectiveness ratio, High strength and bending resistance, large volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

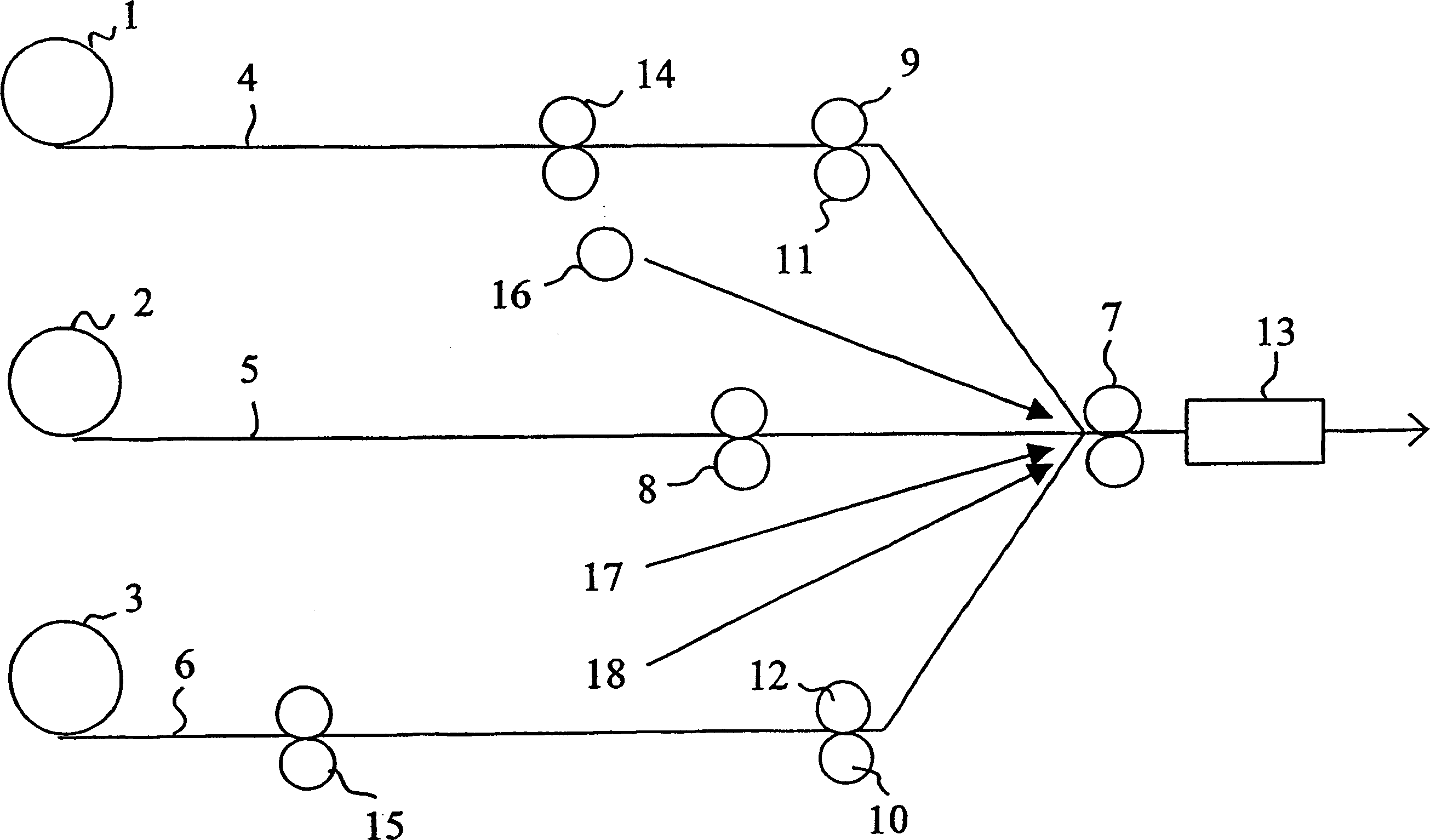

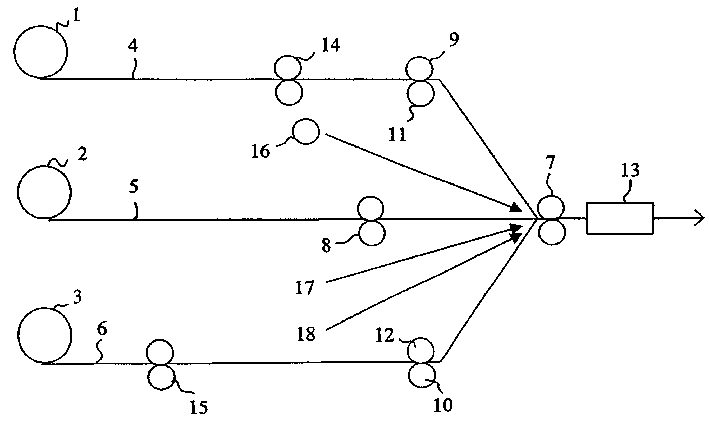

[0018] The example shown in the figure is suitable for the manufacture of three-layer products. To produce such a three-layer product, three coils 4 , 5 , 6 are required, which are fed into the process as coils 1 , 2 , 3 . As this process requires, rolls are paid out from the material rolls 1, 2, 3 and enter a bonding / sizing nip 7 formed between two opposing rolls. The rolls are glued together in the nip 7 . First, the interlayer roll 5 is passed through the nip of an embossing roll 8 which embosses a raised pattern thereon by embossing the web 5 in a dry state, thereby permanently deforming the web surface. In this context dry rolls have to be understood as having the normal moisture content of rolls being paid out from storage rolls or processing rolls 2, ie the moisture content of the delivered coils, generally less than 10% and usually 3%-12%. Additionally, the embossing operation is performed without subjecting the web to heat or steam. Most advantageously, the roll su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com