Swirling-flow noise-reduction joint used in construction drainage

A technology for building drainage and swirling flow, applied in the direction of pipes/pipe joints/pipe fittings, fluid flow, mechanical equipment, etc. Noise effect and other issues, to achieve the effect of increasing drainage capacity, reducing the impact of water hammer, and improving drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

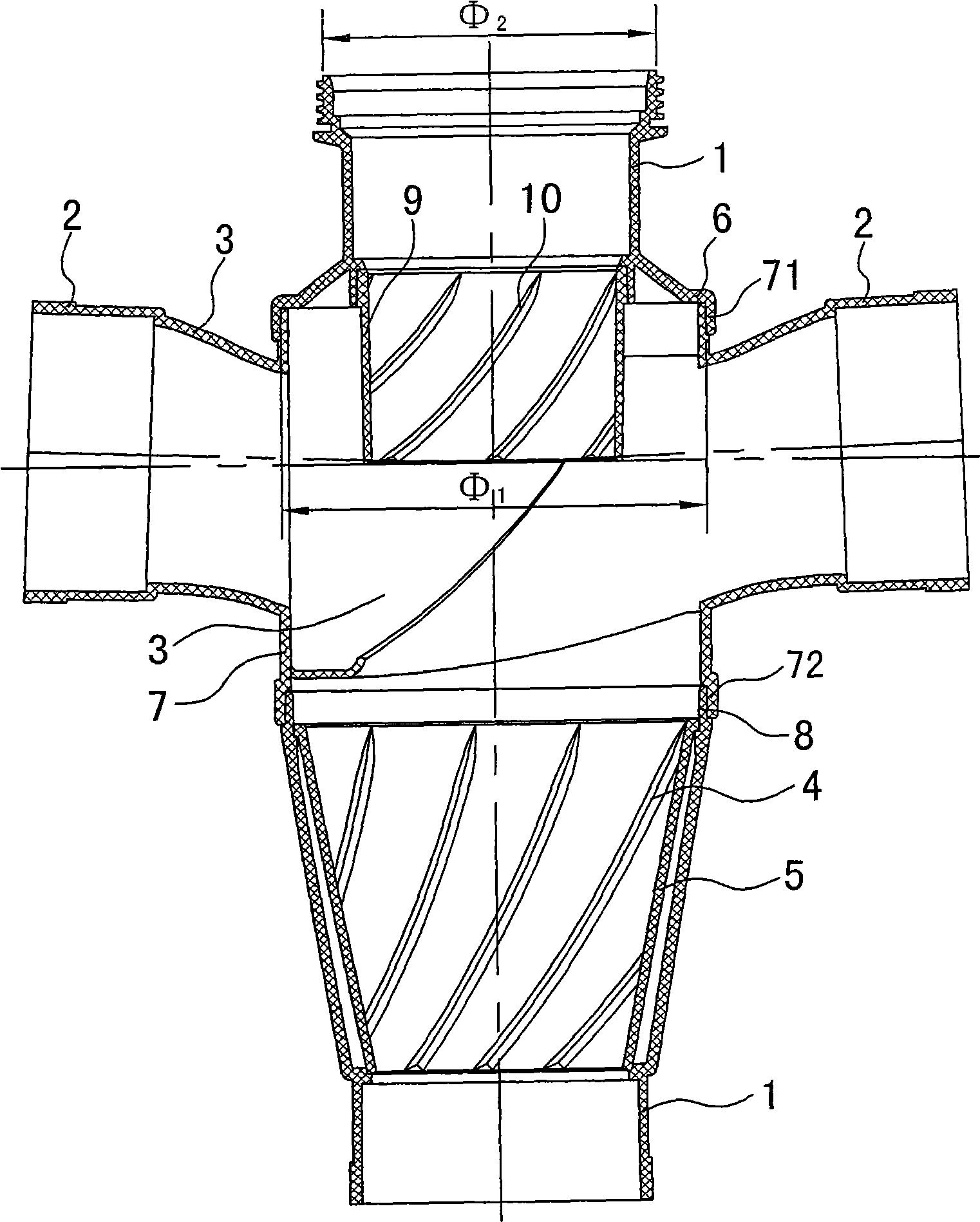

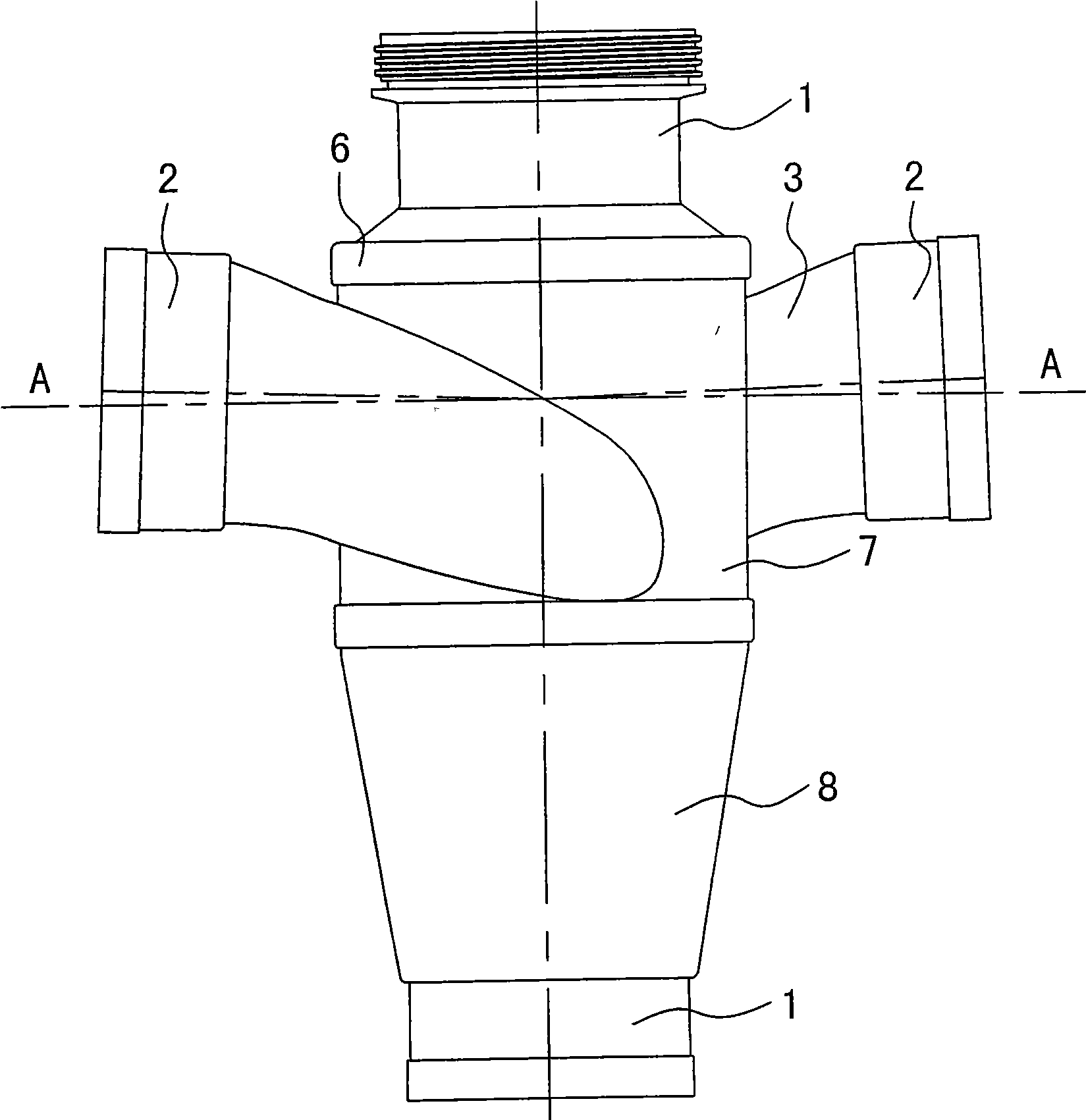

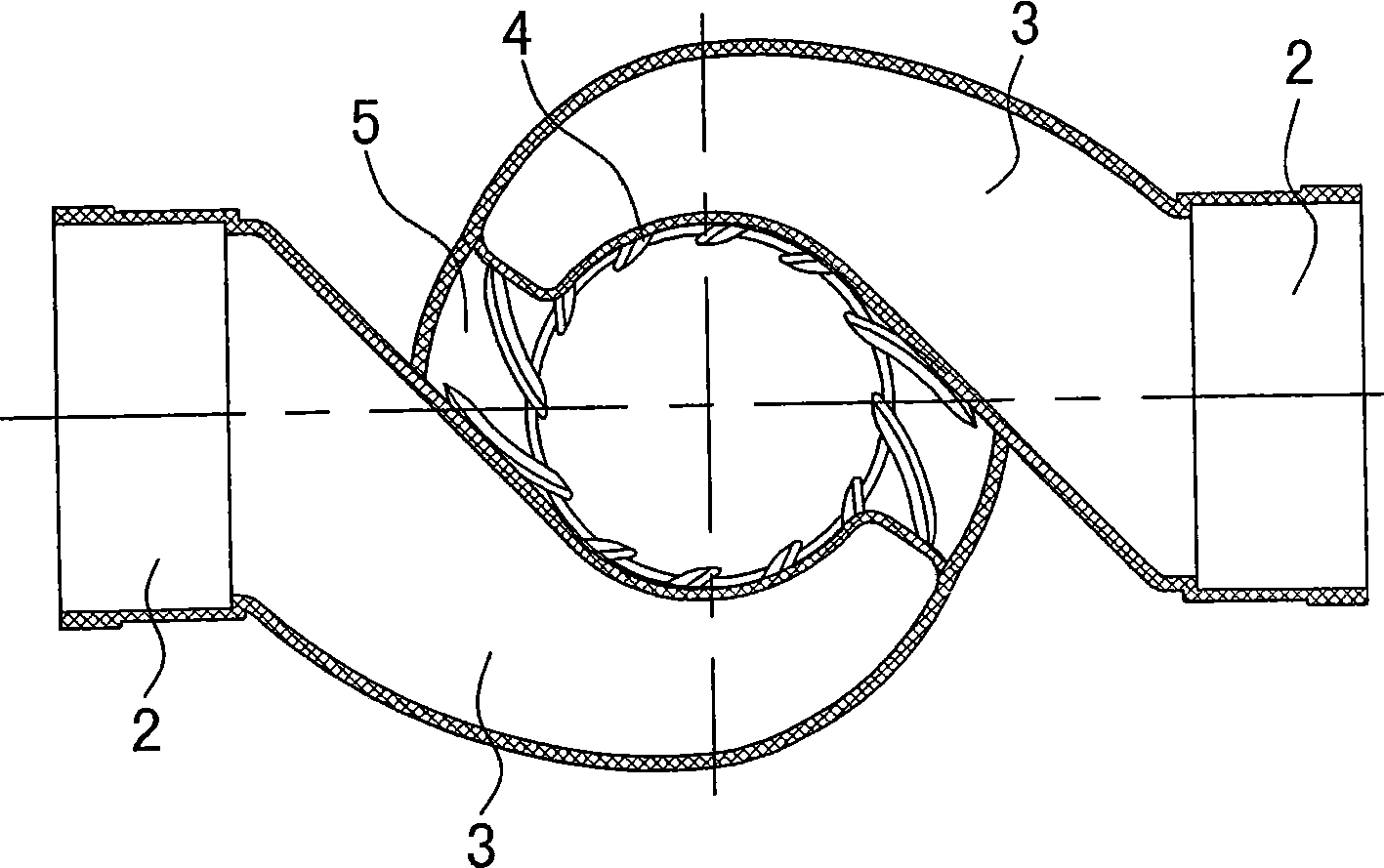

[0010] The invention relates to a swirl flow noise reduction joint for building drainage, such as figure 1 — image 3 As shown, it includes the main body of the joint. There are main riser joints 1 on the upper and lower sides of the main body and lateral branch joints 2 on the side. The main riser connector 8, the lower main riser connector 8 is in the shape of a circular platform funnel, and there is a lower diversion sleeve 5 in the funnel shape, and the inner wall of the lower diversion sleeve 5 is formed with spiral ribs B4, and the transverse branch pipe connector 7 outer diameter Φ 1 Greater than the outer diameter Φ of the upper and lower main riser joints 1 2 , the transverse branch pipe interface 2 is connected to the transverse branch pipe connecting body 7 through the spiral diversion channel 3 . Compared with the prior art, this program has the following advantages: 1. The lower main riser connector 8 is funnel-shaped in shape, has a larger space inside, and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com