Miniature pile model used for model tests and manufacturing method thereof

A manufacturing method and technology of micro-pile, which is applied in the preparation of test samples, the test of foundation structure, construction, etc., can solve the difficulty of realizing monitoring components, the inability to monitor the stress of micro-pile, and the inability to obtain the internal force distribution law of micro-pile and damage modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

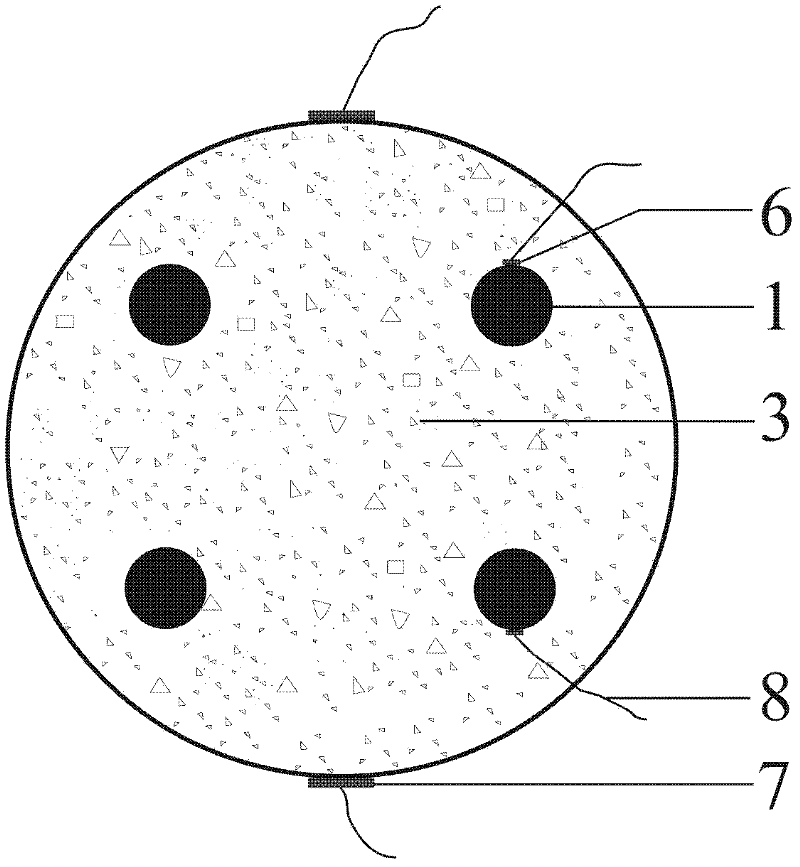

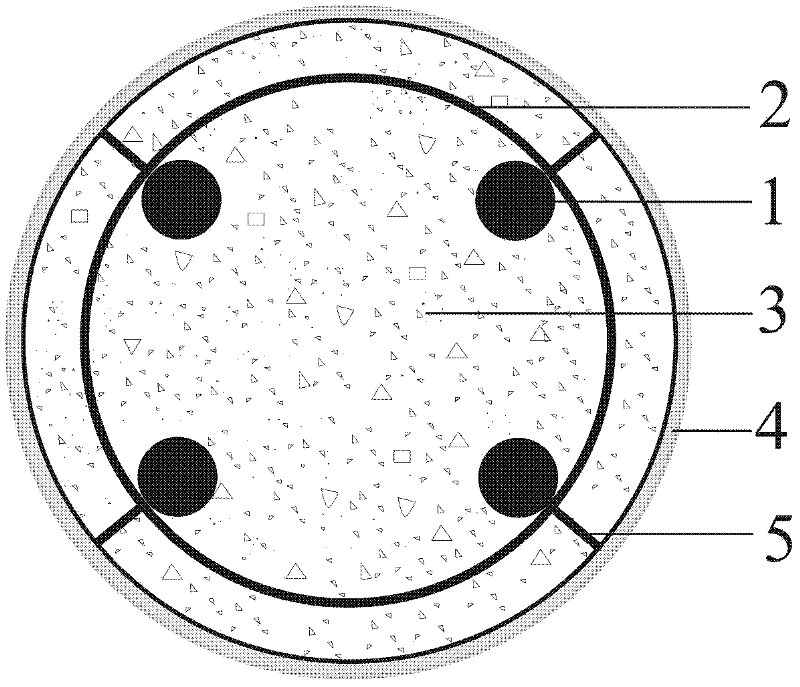

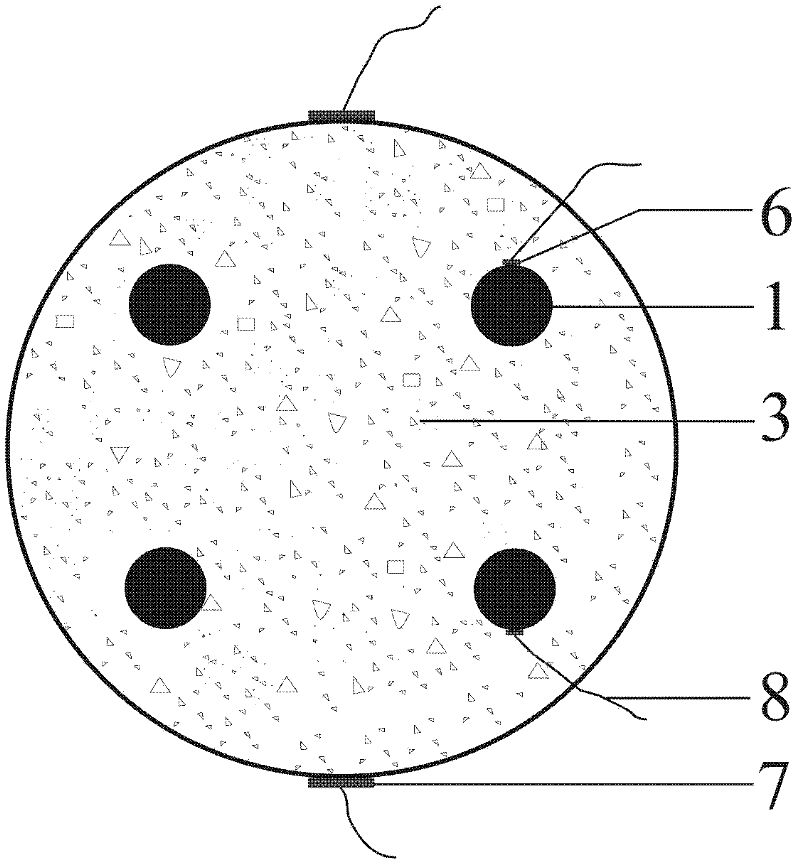

[0019] For further elaborating the technical means and effect that the present invention takes to reach the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the miniature pile model that proposes according to the present invention and its manufacturing method for model test and its specific implementation Mode, structure, feature and effect thereof are as follows in detail.

[0020] The concrete steps of this method include:

[0021] (1) Determination of the parameters of the micropile model.

[0022] The parameters of the micro-pile prototype to be studied are: pile length L=12m, pile diameter D=300mm; the reinforcement uses 6 steel bars with a diameter of d=28mm in the form of a steel cage; the pile body is poured with cement mortar.

[0023] According to the test conditions, determine the pile length L'=2m of the micro-pile model in the test, then the geometric similarity ratio C L =L / L'=6. Determine the material of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com