Method of splicing laminated floor slab and beam

A technology of superimposing floor slabs and slab thicknesses, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of unsatisfactory structural requirements and unreasonable force at joints, and achieve reasonable force and simple construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

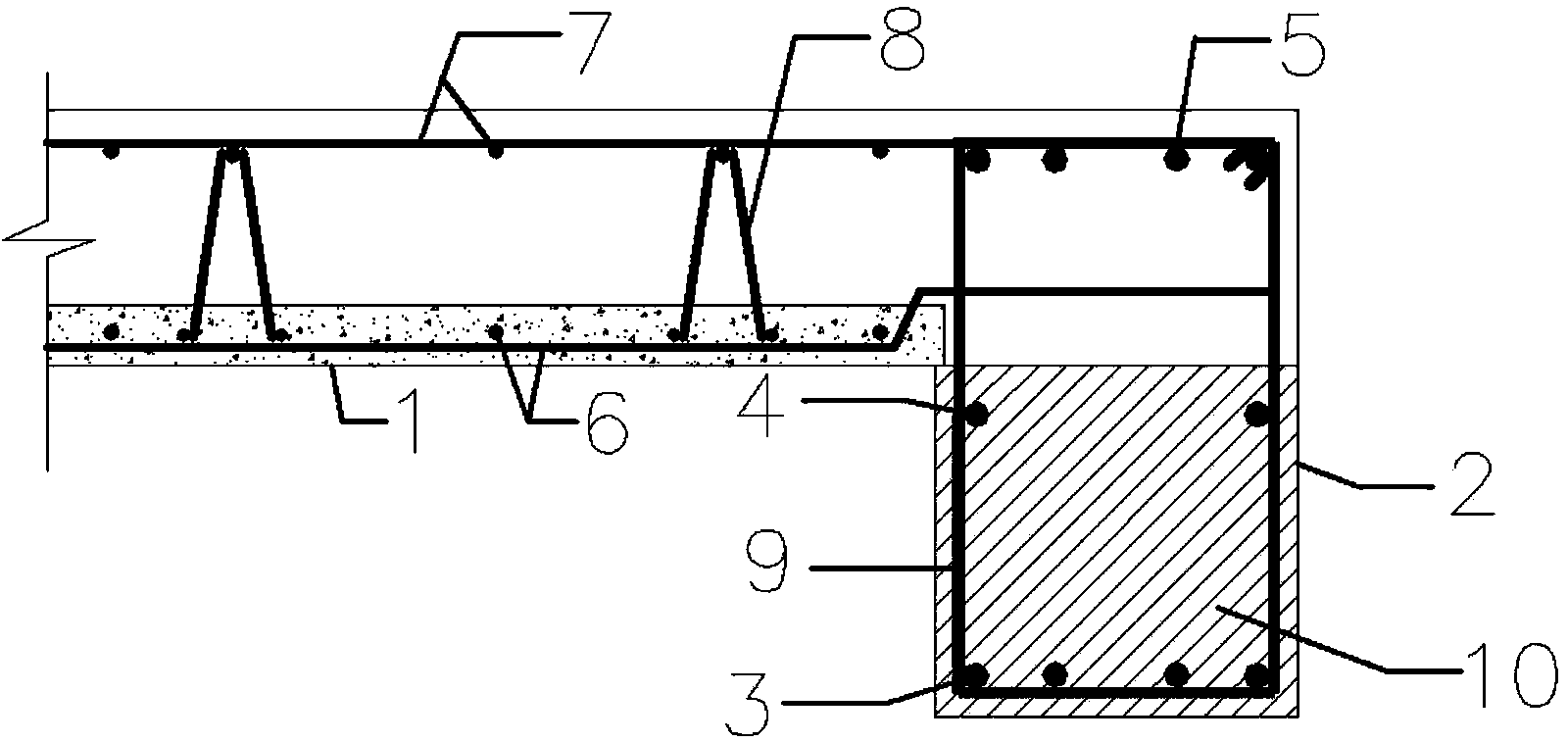

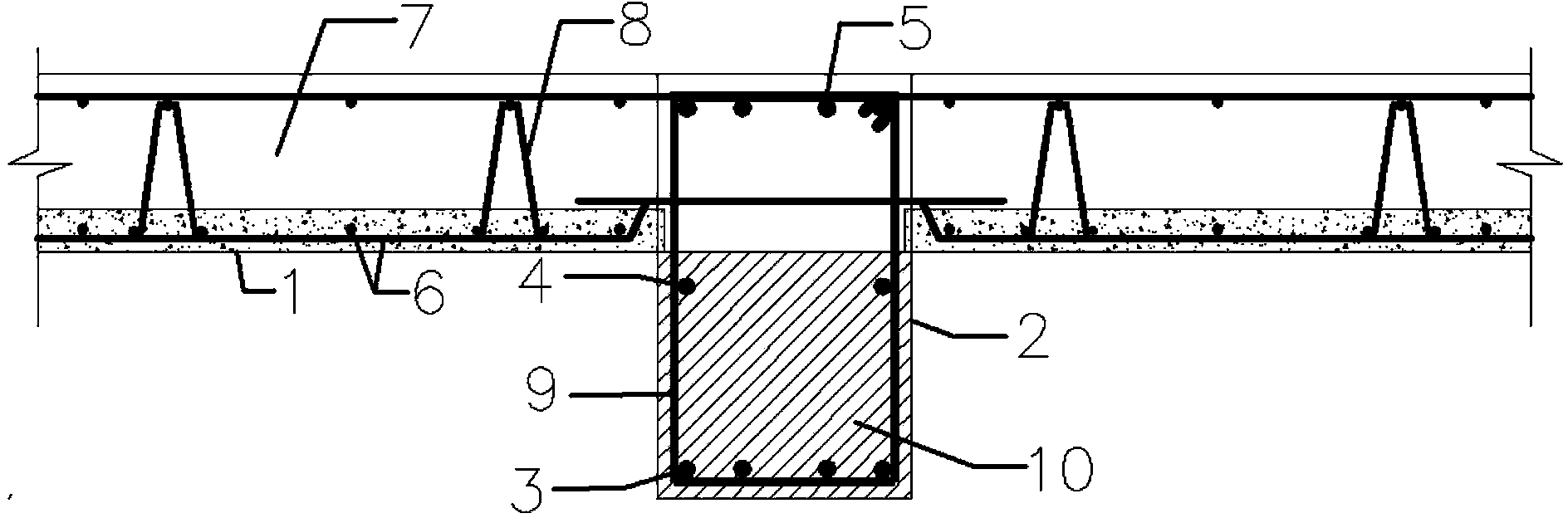

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] like figure 1 and figure 2 As shown, the prefabricated slab is prefabricated in the factory and is composed of slab bottom steel bar 6, truss steel bar 8 and concrete, among which the truss steel bar 8 can control the thickness of the floor slab. The prefabricated panels can act as templates on site, eliminating the need for formwork.

[0014] During on-site construction, first bind the steel bars inside the beam 2, and pay attention to only binding the longitudinal bars 3 at the lower part of the beam, the longitudinal bars 4 at the middle of the beam and the stirrup bars 9 during the first pouring. The height of the formwork should not be higher than the difference between the beam height and the plate thickness when the beam formwork is supported. After the formwork is completed, the concrete is poured, and the first pouring part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com