Digging laneway aerating and dust removing system arrangement method

A technology of dust removal system and layout method, which is applied to ventilation, dustproof and safety devices in mines/tunnels, can solve problems such as poor dust removal effect and difficulty in capturing dust, and achieve low water consumption, reasonable ventilation layout, and dust removal effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

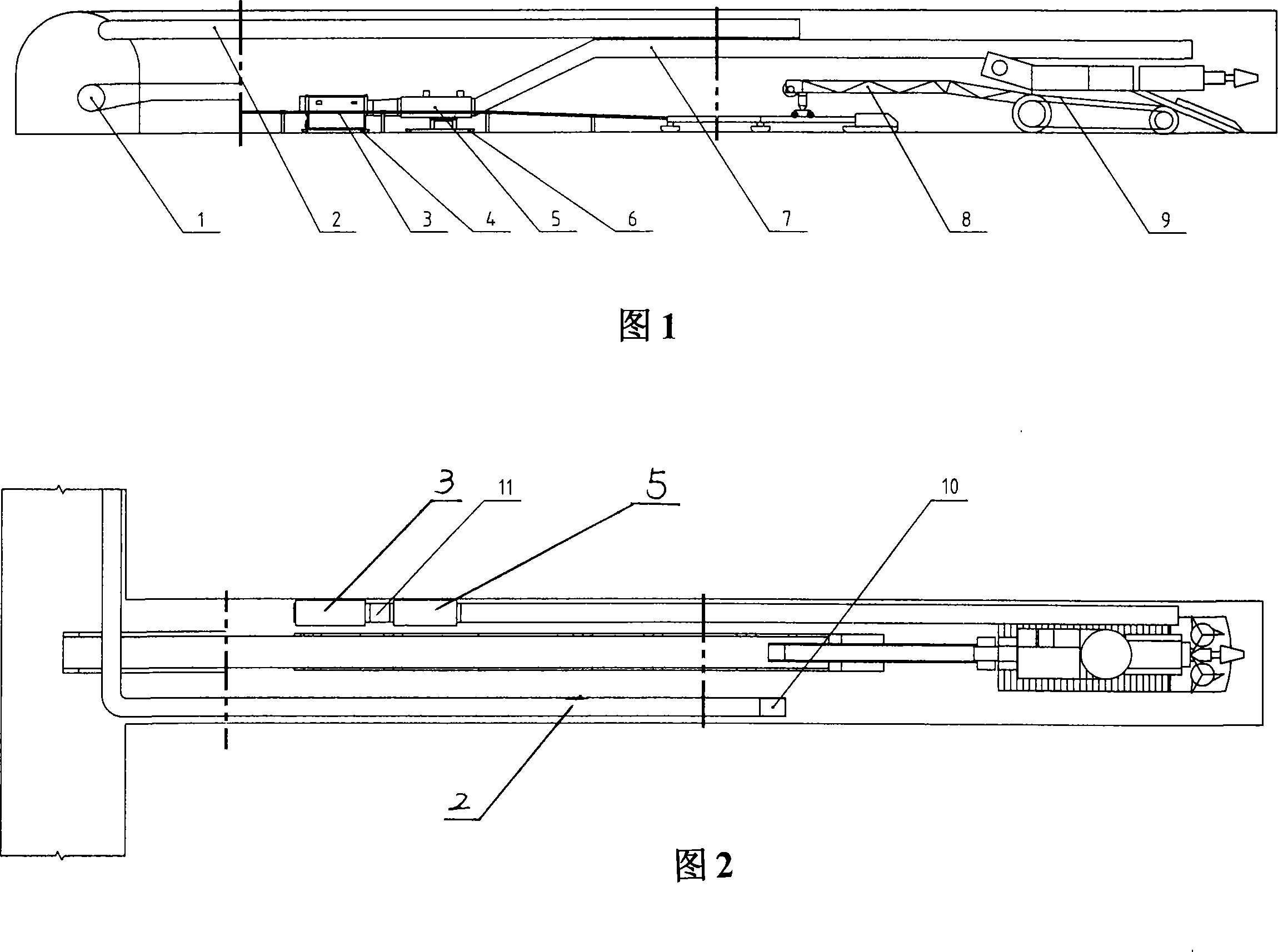

Embodiment 1

[0019] Embodiment 1, the basic machine excavation ventilation and dust removal system, it mainly consists of a belt conveyor 1, two positive pressure air cylinders 2, 11, a dust collector 3, a dust collector skid 4, a fan 5, a fan skid 6, and a negative pressure air cylinder. Tube 7, belt transfer machine 8, roadheader 9, cyclone 10 and other components. The connection relationship and installation position of each component are shown in the structural diagram 1 and attached drawing 2. The roadheader 9 and the belt transfer device 8 are connected in the form of docking; the transfer device 8 is erected on the belt conveyor 1 . The negative pressure air cylinder 7 is connected with the blower fan 5 by a clamp, and the negative pressure air cylinder 7 is hung on the roadway. The dust remover 3 is erected on the dust remover skid 4. The fan 5 is erected on the fan skid 6, and the fan 5 is connected with the positive pressure air cylinder 11 by a clamp. The positive pressure air...

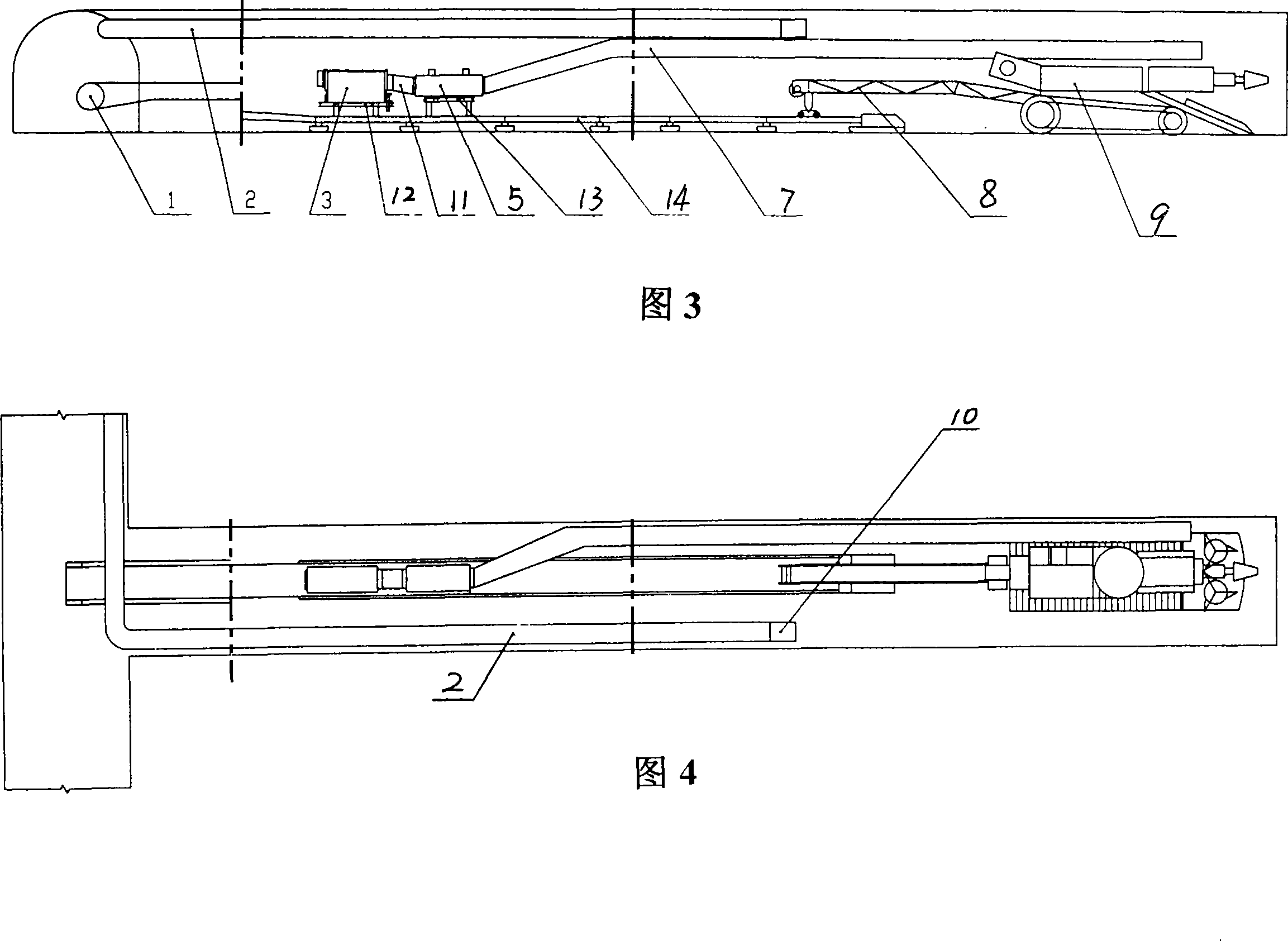

Embodiment 2

[0021] Embodiment 2, fixed frame belt conveyor tail machine excavation ventilation and dust removal system, it mainly consists of belt conveyor 1, positive pressure air cylinder 2, 11, dust collector 3, blower fan 5, negative pressure air cylinder 7, belt transfer machine 8, tunneling Machine 9, cyclone 10, dust collector support 12, fan support 13, belt conveyor tail 14 and so on. The connection relationship and installation position between the various components are shown in the structural diagram 3 and Figure 4. The roadheader 9 is connected with the belt transfer device 8 in a docking form; the transfer device 8 is erected on the tail 14 of the belt conveyor; 5 is connected by a clamp; the negative pressure air cylinder 7 is hung on the roadway; the dust collector 3 is erected on the dust collector support 12; the fan 5 is erected on the fan support 13; the fan 5 and the positive pressure air cylinder 11 are connected by a clamp; The positive pressure air cylinder 11 and ...

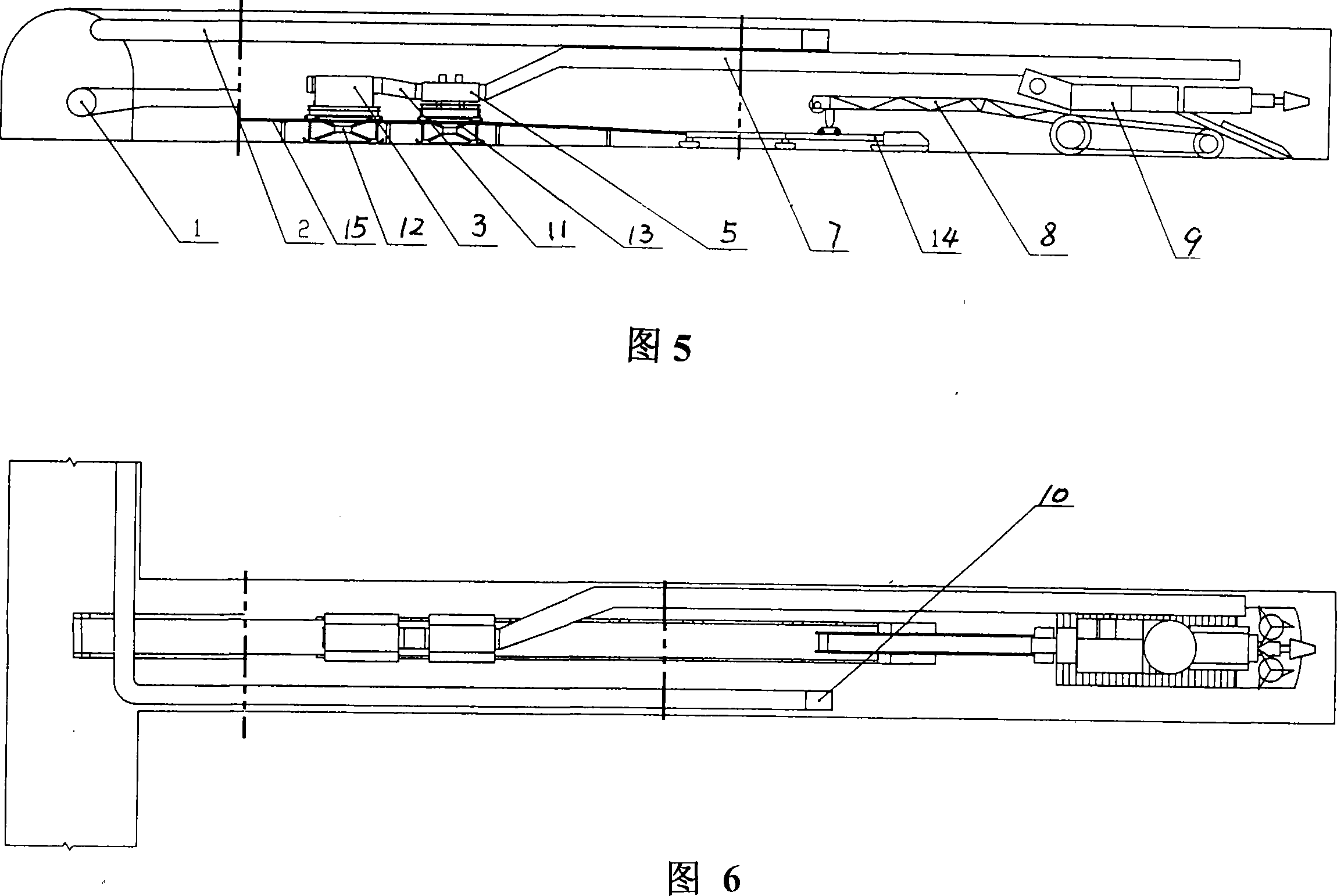

Embodiment 3

[0024] Embodiment 3: Cross-belt longitudinal beam machine digging ventilation and dust removal system, which mainly consists of belt conveyor 1, positive pressure air cylinder 2, belt longitudinal beam 15, dust collector support 12, dust collector 3, positive pressure air cylinder 11, fan support 13. Fan 5, negative pressure air cylinder 7, belt conveyor tail 14, belt transfer machine 8, roadheader 9, cyclone 10, etc. The connection relationship and installation position between the various components are shown in the structural diagrams 5 and 6. The roadheader 9 and the belt loader 8 are connected in a docking form; the belt loader 8 is erected on the tail 14 of the belt conveyor; 5 is connected by clamps; the negative pressure air cylinder 7 is hung on the roadway; the fan 5 and the dust collector 3 are erected on the fan bracket 13 and the dust collector bracket 12; the dust collector bracket 12 and the fan bracket 13 are straddled on the belt longitudinal beam 15 Above; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com