Novel reinforced-concrete combined pier column and construction method thereof

A technology of reinforced concrete and construction method, applied in bridge parts, bridge materials, bridges, etc., can solve problems such as failure, degradation of bearing capacity of ordinary reinforced concrete columns, and maintenance of bearing capacity of components, so as to improve concrete strength and enhance earthquake resistance. Performance and repairability, the effect of enhanced seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

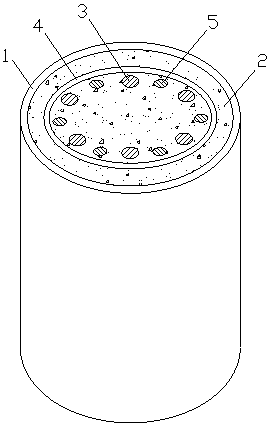

[0023] In Example 1: as figure 1 As shown, six ordinary steel bars 3 and six fiber bars 5 are arranged at equal intervals, and the cross-section of the fiber-reinforced composite material tube 1 is circular.

Embodiment 2

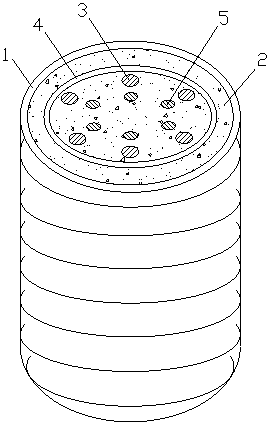

[0024] In Example 2: such as figure 2 As shown, six ordinary steel bars 3 and six fiber bars 5 are arranged in layers, six ordinary steel bars 3 are equally spaced to form an outer ring, and six fiber bars 5 are equally spaced to form an inner ring; the fiber reinforced composite material pipe 1 is composed of Made of unidirectional fiber cloth, the cross-section of the fiber reinforced composite material pipe 1 is circular, and the outer ring and the inner ring are concentric with the fiber reinforced composite material pipe 1 .

Embodiment 3

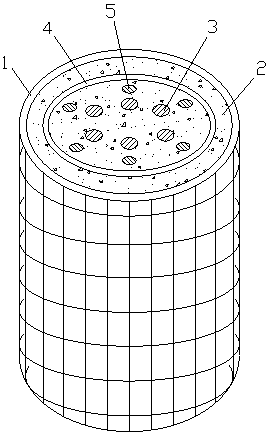

[0025] In Example 3: as image 3 As shown, six ordinary steel bars 3 and six fiber bars 5 are arranged in layers, six ordinary steel bars 3 are equally spaced to form an inner ring, and six fiber bars 5 are equally spaced to form an outer ring; the fiber reinforced composite material pipe 1 is composed of Made of two-way fiber cloth, the cross-section of the fiber reinforced composite material tube 1 is circular, and the outer and inner rings are concentric with the fiber reinforced composite material tube 1 .

[0026] In Example 3: as Figure 4 As shown, four common steel bars 3 and four fiber bars 5 are arranged at equal intervals, the cross-section of the fiber-reinforced composite material tube 1 is rectangular, and the four common steel bars 3 are respectively located at four right angles of the rectangular stirrup 4. The root fiber bars 5 are respectively located at the midpoints of the four sides of the rectangular stirrup 4 .

[0027] In the above embodiment, the fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com