Bridge jacking counter-force device suitable for narrow and small space between beam bottom and cover beam

A technology of small space and counter force device, which is applied in the direction of bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as poor economy, damage to cover beams, large construction scale, etc., to save manpower and material resources, and the device has a small weight and is good. The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings of the description.

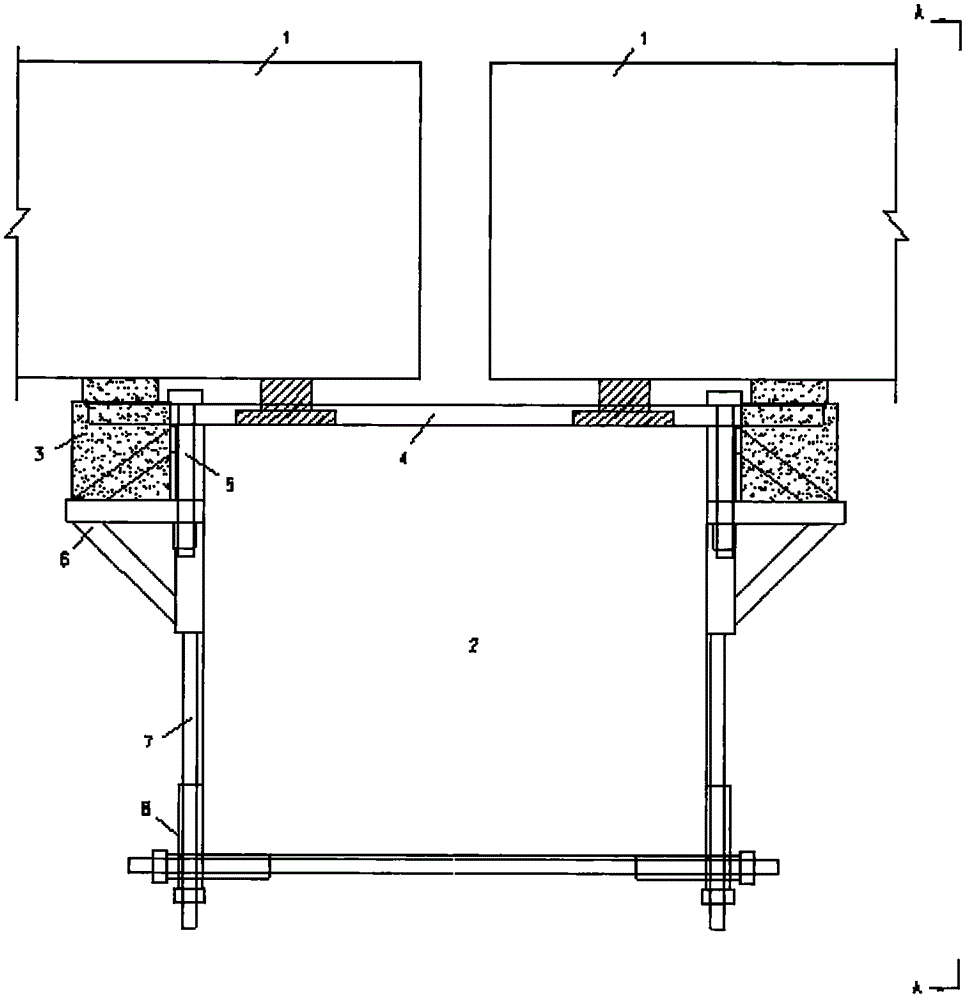

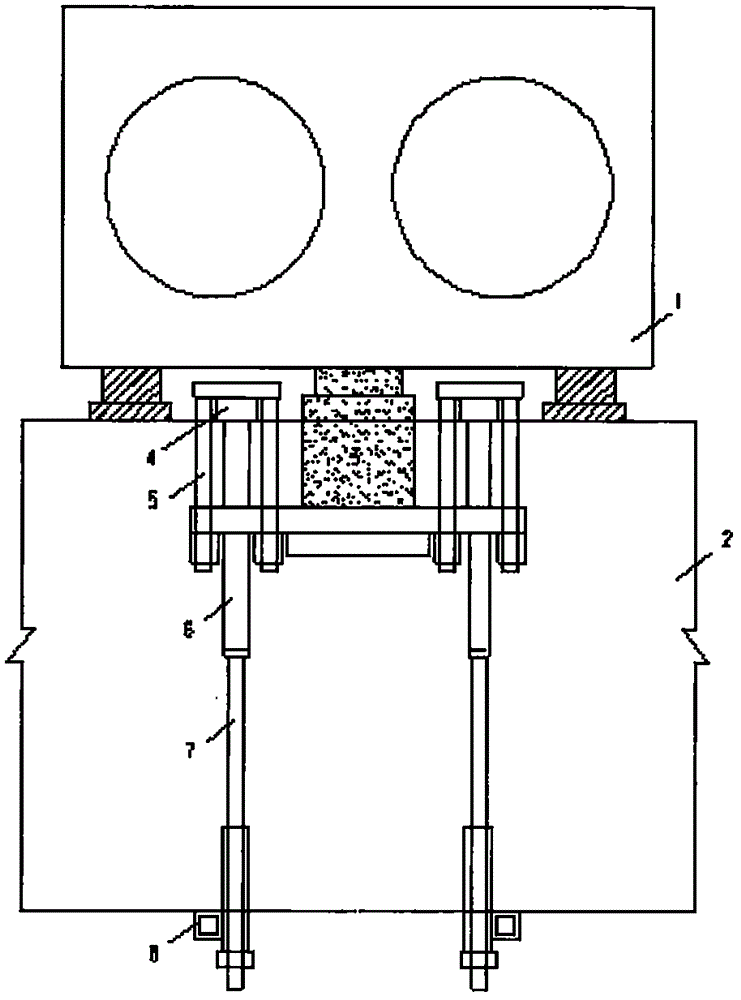

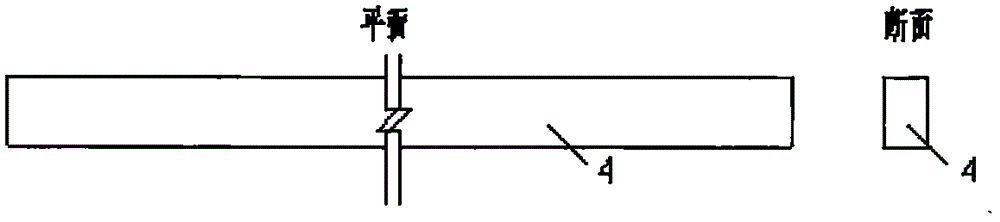

[0029] A sort of Figure 1 to Figure 9 The bridge jacking reaction force device of the present invention applicable to the narrow space between the bottom of the beam and the cover beam is shown. The beam 4 is equipped with a platform structure 6 on both sides of the cover beam. The two are reliably connected by a special high-strength bolt collar 5. The vertical screw 7 of the holding device is connected to the bottom of the platform structure through a threaded hole. The vertical screw 7 of the holding device The other end is reliably connected with the clamping device transverse screw 9 through the clamping device 8 . The whole device can be used after being reliably connected with the cover beam through the above method. When in use, the jack 3 is placed on the platform structure 6. In order to ensure that the device is safer and more reliable, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com