Steel frame precast prestressed beam column joint with post-earthquake recovering function

A technology of beam-column joints and recovery functions, applied in the field of steel structure joints, can solve the problems of prolonging the construction time of steel frames, hindering the application of steel frame structure systems with recoverable functions, and increasing the difficulty of steel frame construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

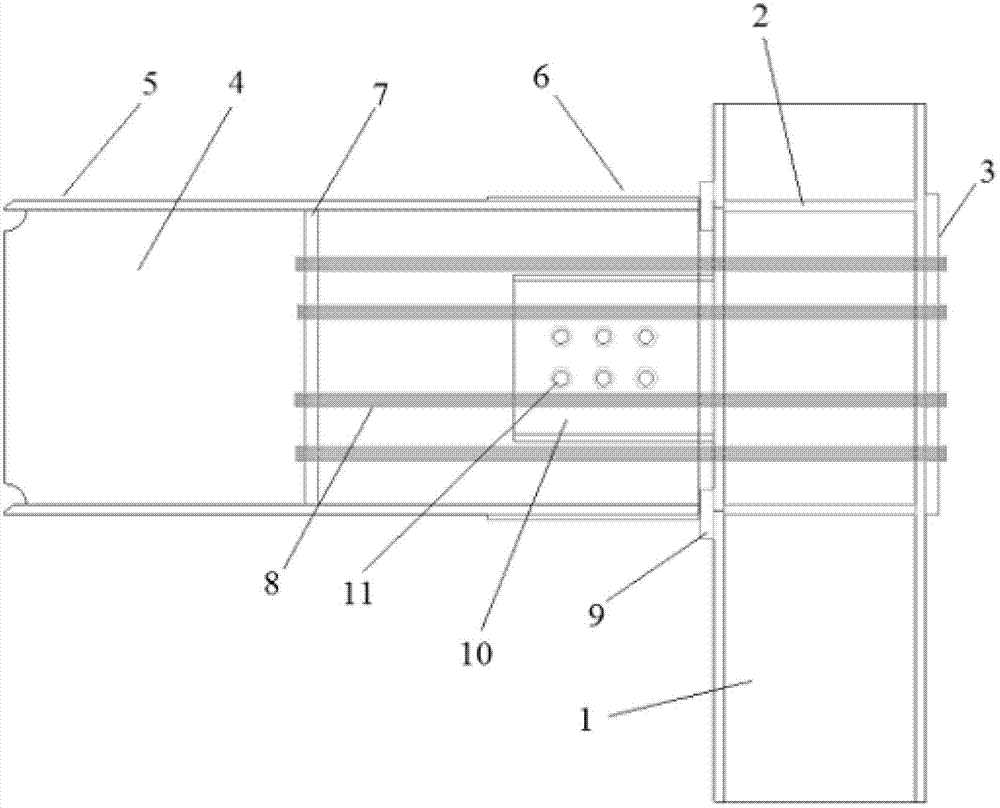

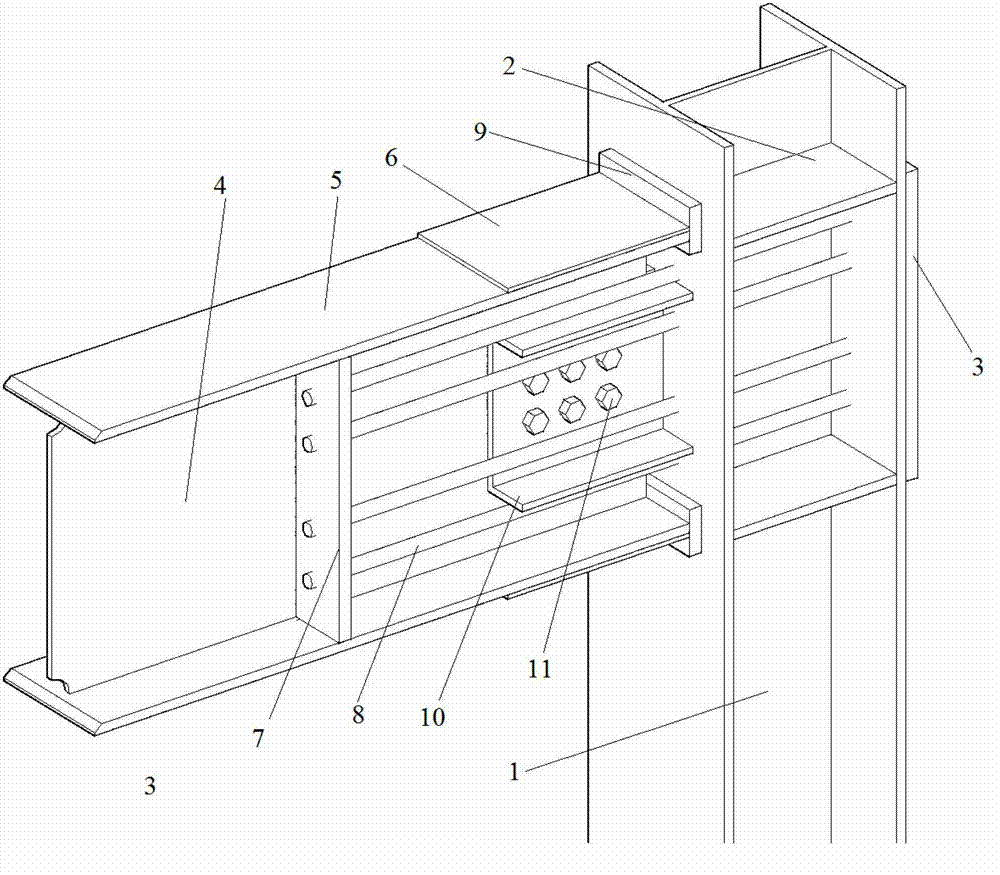

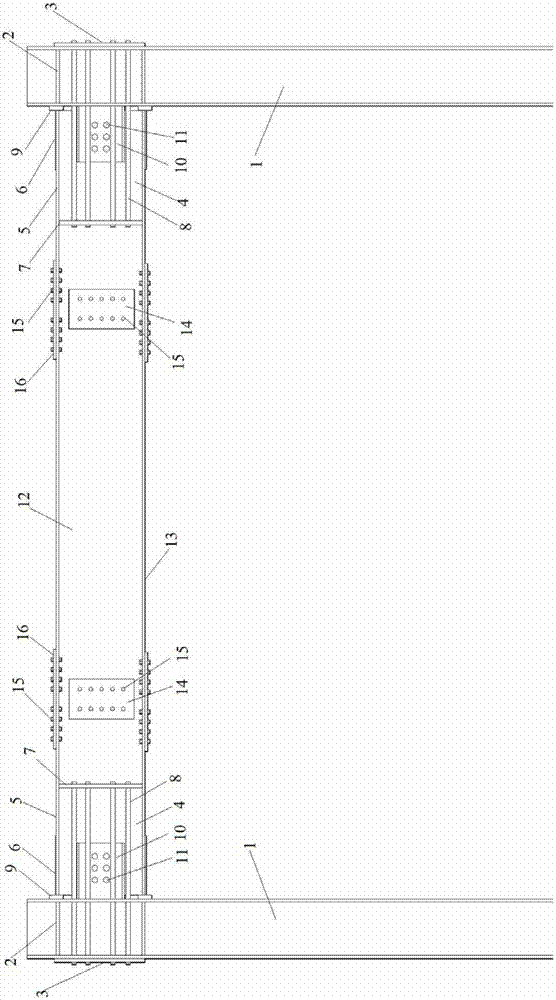

[0037] Such as Figure 1-12 As shown, a post-earthquake recoverable prefabricated prestressed steel frame beam-column joint, including steel frame columns and short beam sections, beam-column connection devices and energy dissipation devices; it is characterized in that: the steel frame columns include steel columns 1. The column stiffener 2 welded at the position flush with the flange of the steel column 1 and the column stiffener 3 welded at the outer side of the flange of the steel column 1 corresponding to the beam; the short beam section includes the short beam section web 4 and welded The short beam section flange 5 at the edge of the short beam section web and the short beam section flange reinforcement plate 6 connected to the upper and lower flange positions at the end of the short beam section; The web stiffener 7 of the short beam section, the prestressed cables 8 and the beam end top plate 9 at the contact position between the flange of the steel column and the sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com