Press fitting tool for assembling elastic cylindrical pin

A technology of elastic cylindrical pins and press-fitting tools, which is applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low pass rate, low work efficiency, low work efficiency, etc., so as to improve the assembly pass rate and reduce labor. Strength, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

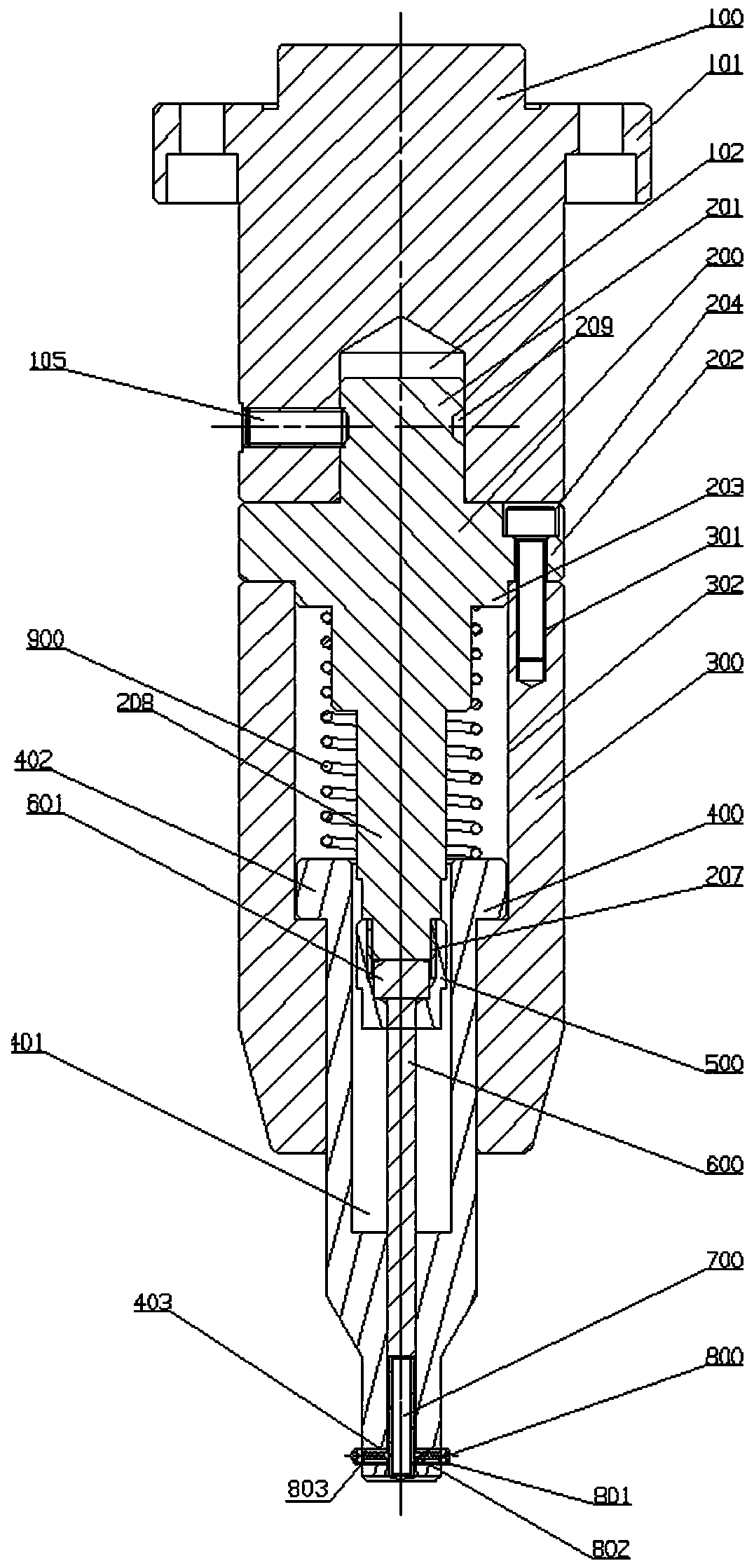

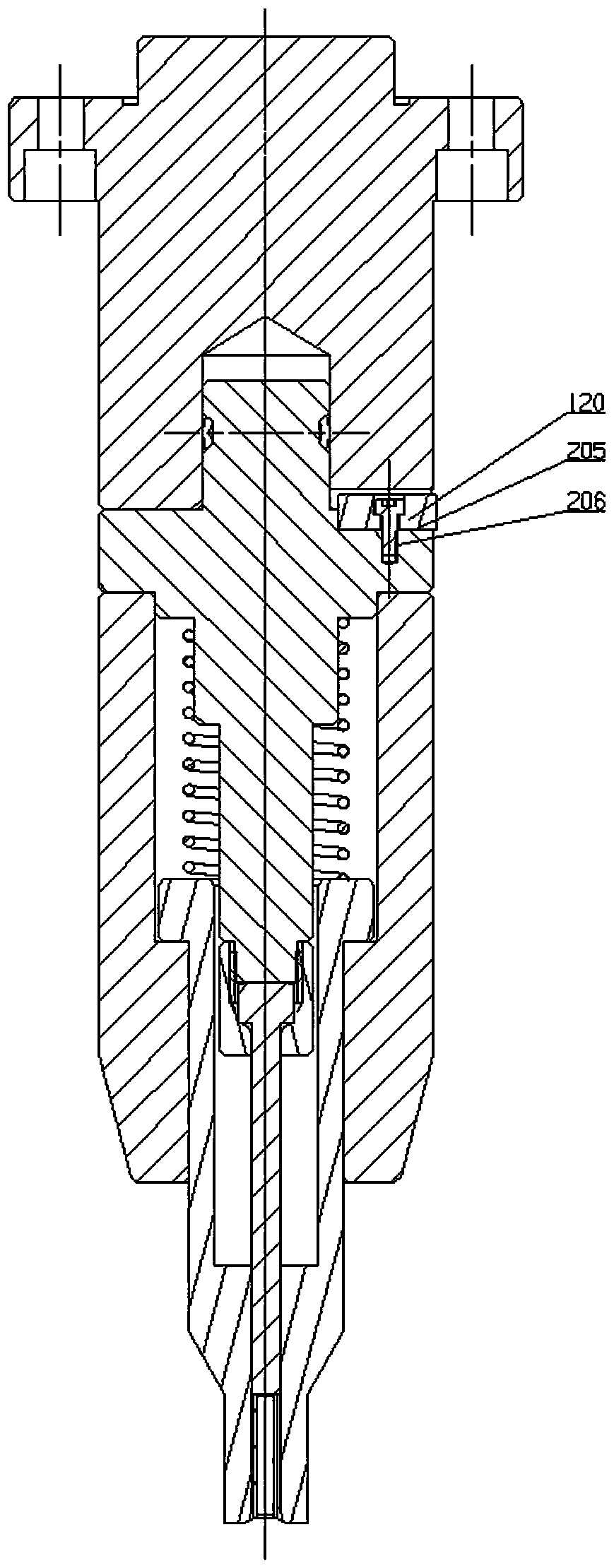

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

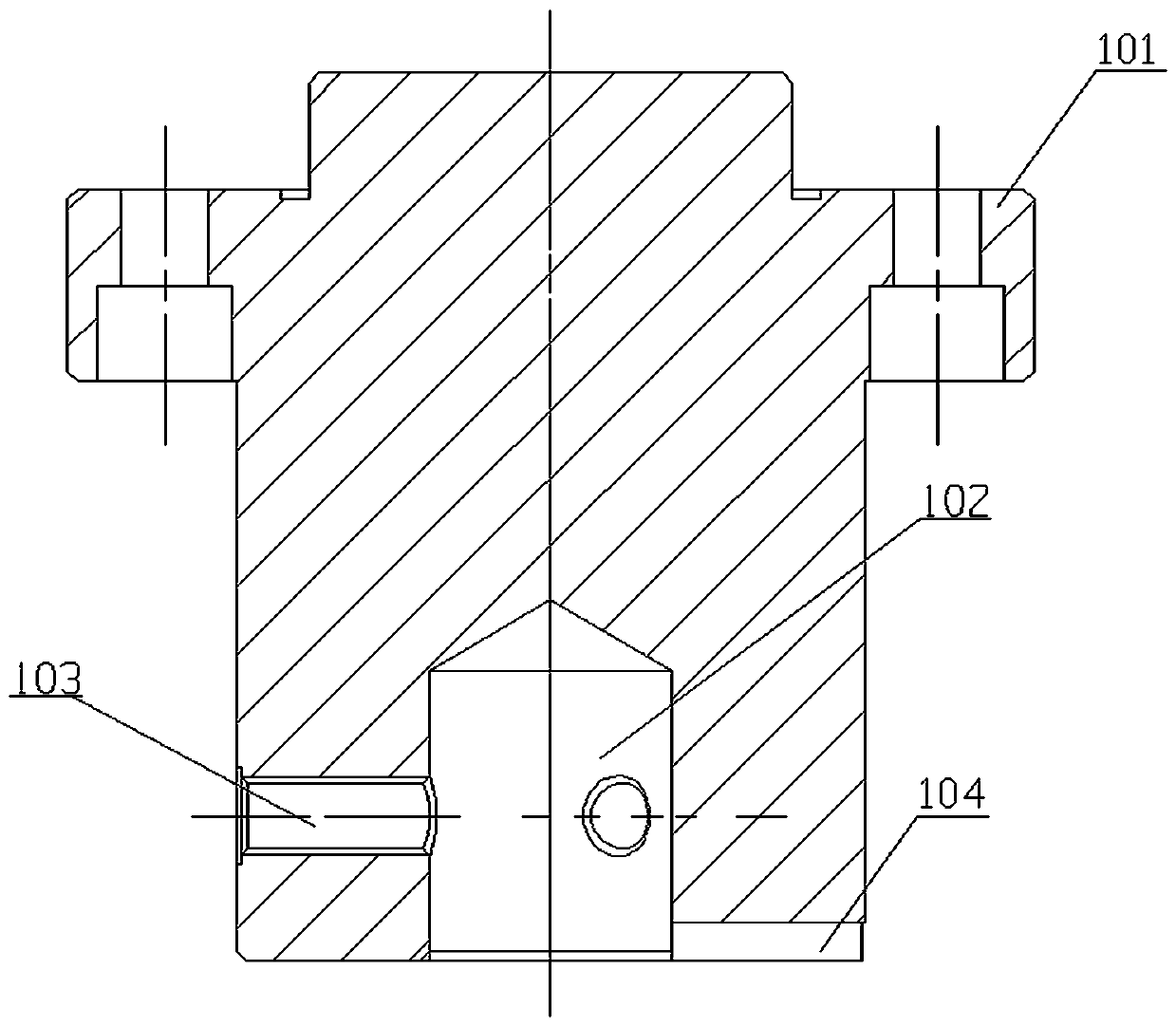

[0024] see Figure 1 to Figure 8, a pressing tool for assembling elastic cylindrical pins, comprising an indenter seat 100, a push head 200, a guide outer cover 300, a guide inner sleeve 400, and a push rod 600, the indenter seat 100, a push head 200, a guide outer cover 300, The guide inner sleeve 400, the nut 500, the push rod 600, and the first compression spring 900 have the same central axis. The axis of the indenter seat 100 is provided with an assembly blind hole 102 with an opening downward, and the side wall of the assembly blind hole 102 is provided with a radial threaded through hole 103, and the radial threaded through hole 103 can be set in multiples. In this embodiment, it is better to set three, and the three radial threaded through holes 103 are evenly distributed on the circumference of the indenter seat 100 . The upper sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com