Assembly process of electromagnetic switch of automobile starter

An electromagnetic switch and assembly process technology, which is applied in the direction of circuits, relays, electrical components, etc., can solve the problems of unsatisfactory precision and size, deviation of the first riveting point, and low efficiency, so as to improve the assembly qualification rate and reduce the Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

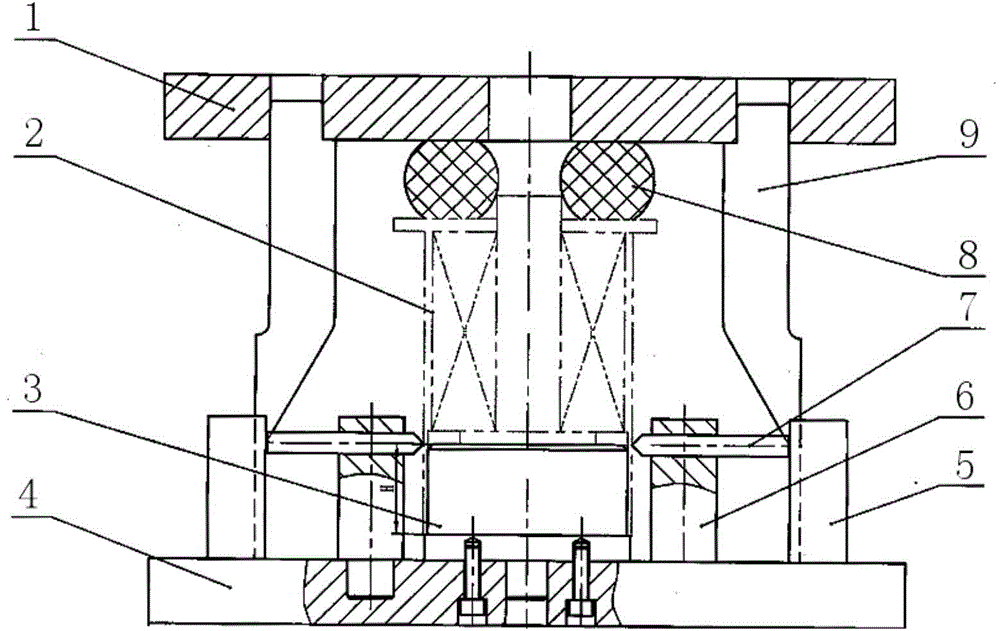

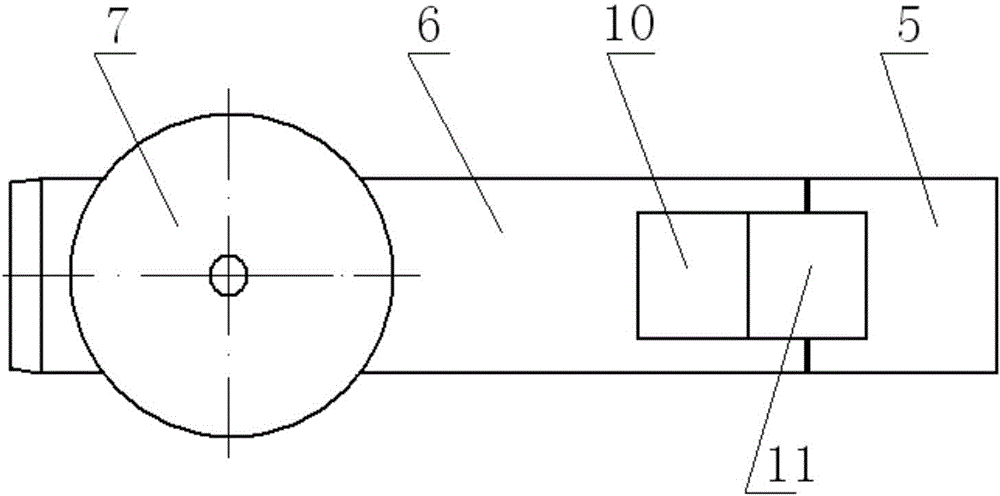

[0017] The assembly process of the electromagnetic switch of the automobile starter is as follows: 1. Riveting the coil assembly and the switch housing as one; 2. Installing the moving core machine assembly and the static core machine assembly; The end of the layer and the end of the outer layer pass through the bakelite end cap together, and the beginning of the inner layer and the beginning of the outer layer pass through the end of the bakelite together; 4. Weld the beginning of the inner layer and the beginning of the outer layer firmly, and weld the end of the inner layer firmly. In step 1, riveting the coil assembly and the switch housing as a whole is carried out on the designed riveting device, such as figure 1 , figure 2 As shown, the riveting device is composed of an upper mold and a lower mold. The upper mold includes an upper mold 1, a rubber fixing ring 8 and four wedge knives 9, and the four wedge knives 9 are vertically and evenly distributed on the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com