PCB plug-in feeding system for guiding installation through utilizing laser

A feeding system and laser-guided technology, applied in the direction of electrical components, electrical components, conveyor objects, etc., can solve problems such as low production efficiency and error-prone plug-in assembly, so as to reduce production and assembly costs, improve assembly pass rate, and improve The effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

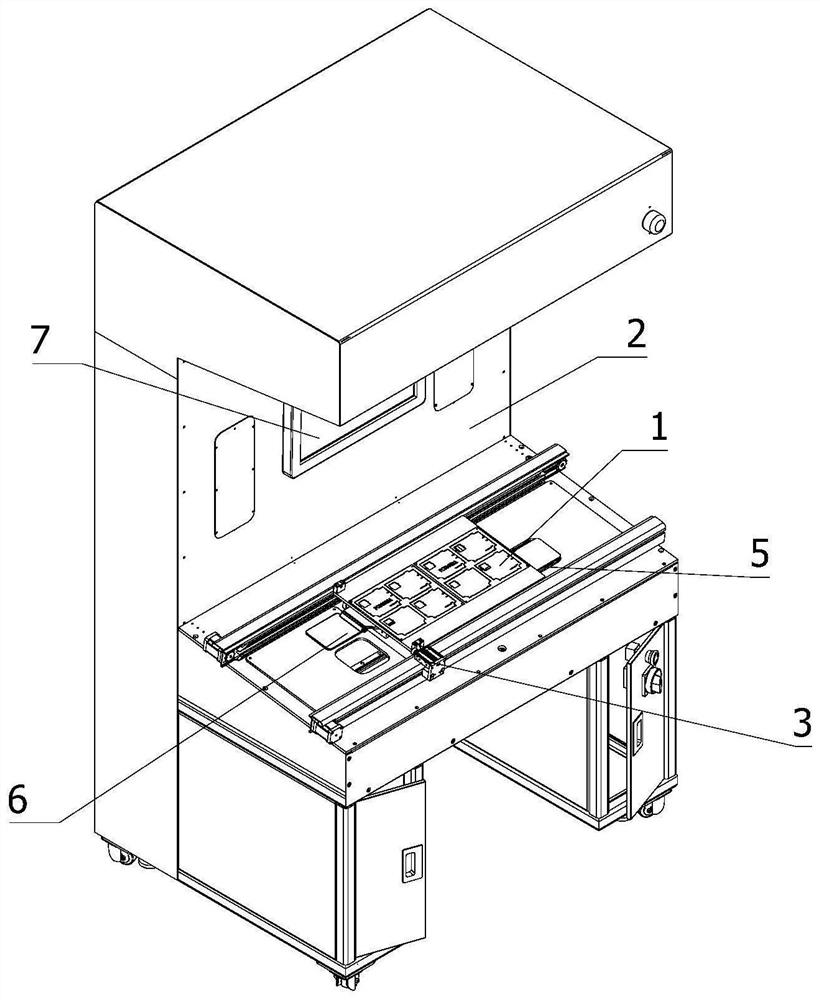

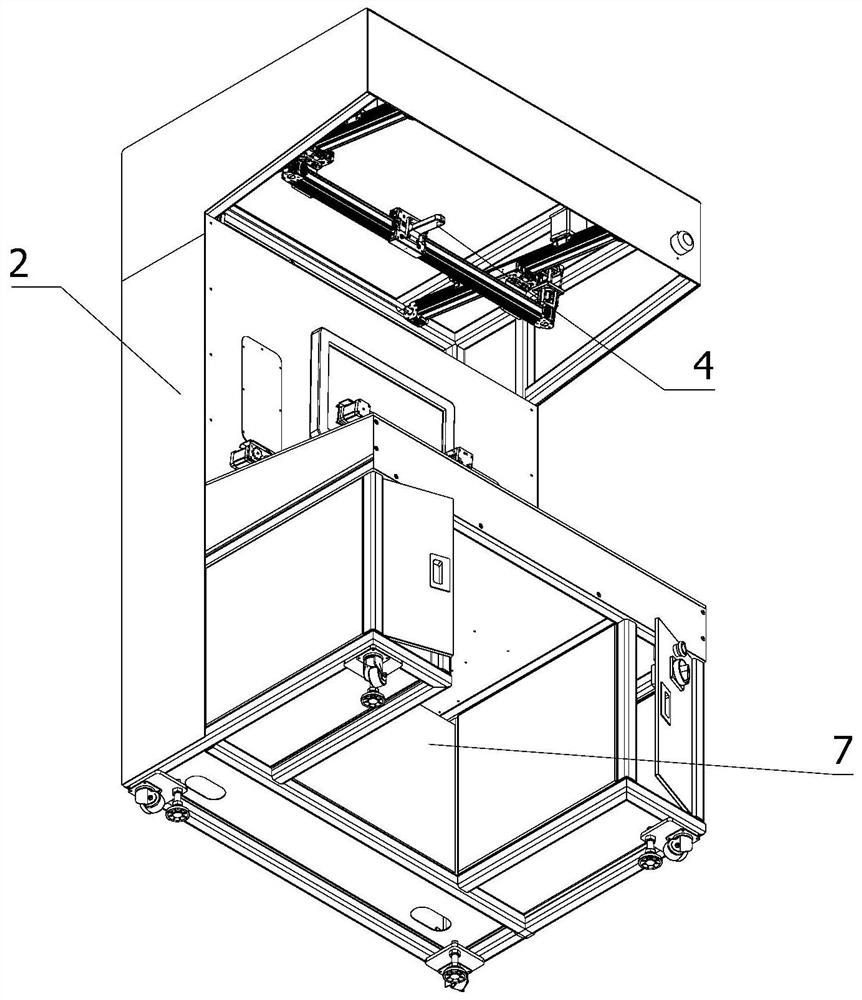

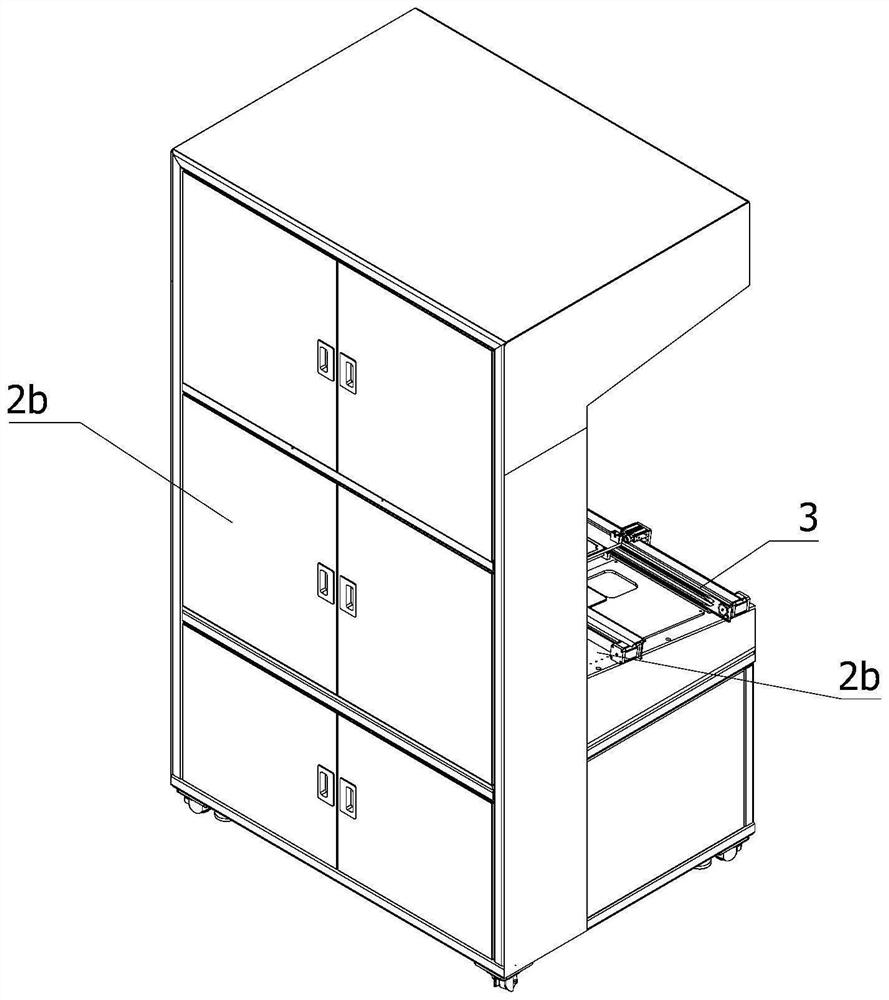

[0041] Such as Figure 1-13 Shown:

[0042] A PCB plug-in feeding system guided and installed by laser, including a PCB board 1, a frame 2, a positioning installation mechanism 3, a laser guiding mechanism 4, a feeding mechanism 5, a retrieving mechanism 6 and an electric control system 7 , the middle part of the frame 2 is provided with an inclined operating platform 2a, and the positioning installation mechanism 3 is arranged on the inclined operating platform 2a. At the top of the frame 2, the length direction of the tilting operation platform 2a is set as the X-axis direction, and the tilting direction of the tilting operation platform 2a is set as the Y-axis direction. 4a, the output end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com