An intelligent conveying software and hardware integrated assembly system and process

A technology of intelligent transportation, software and hardware, applied in the direction of general control system, control/regulation system, program control, etc., can solve the problems of low efficiency of manual reading of drawings, high labor intensity of operators, and long complete cycle, etc., to achieve automation hardware Assembly and software integration, intelligent delivery and distribution, and reduced development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be clearly and completely described below.

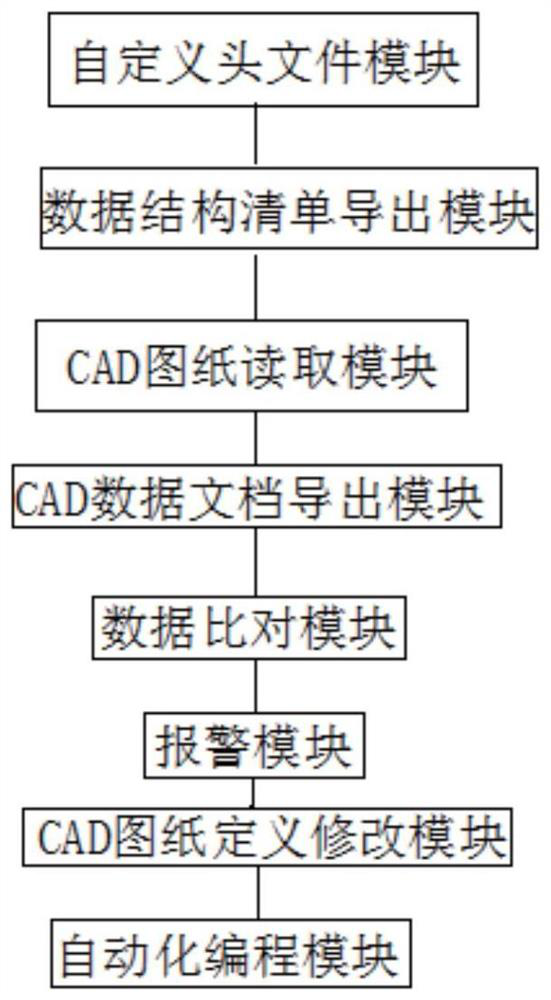

[0051] Such as figure 2 As shown, an intelligent conveying software and hardware integrated assembly system includes:

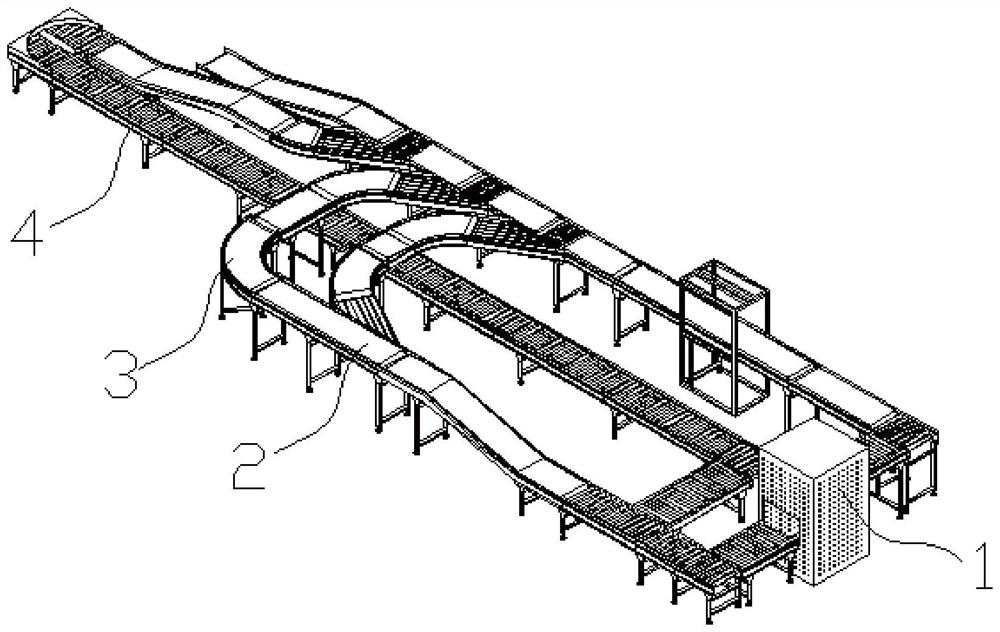

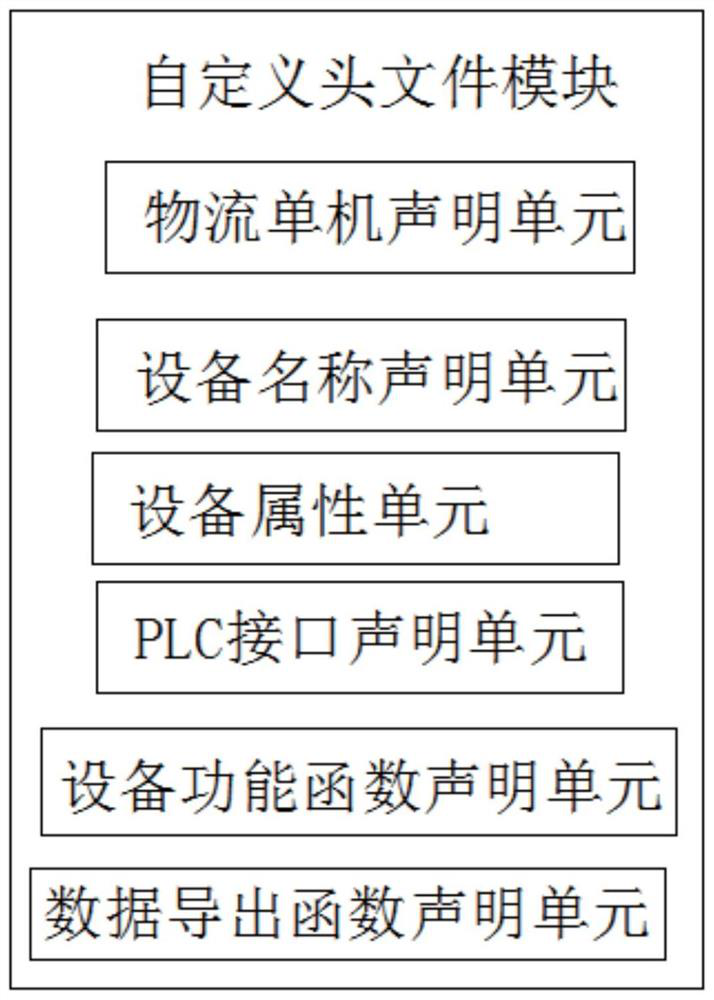

[0052] Custom header file modules such as image 3 As shown, it includes a logistics stand-alone declaration unit, a device name declaration unit, a PLC interface declaration unit, and a device function declaration unit. , PLC interface, and equipment function functions are defined and declared; it should be noted that the logistics machine is composed of a hoist 1, a belt conveyor 2, a turning machine 3, a roller conveyor 4 and other logistics stand-alone machines. For block design and naming, each logistics stand-alone machine is composed of basic equipment such as sensors, pneumatic motors, and motors, and is controlled by PLC. This is a conventional technical means in the field, and will not be repeated here.

[0053] The intelligent transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com