Patents

Literature

32results about How to "Reduce assembly error rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

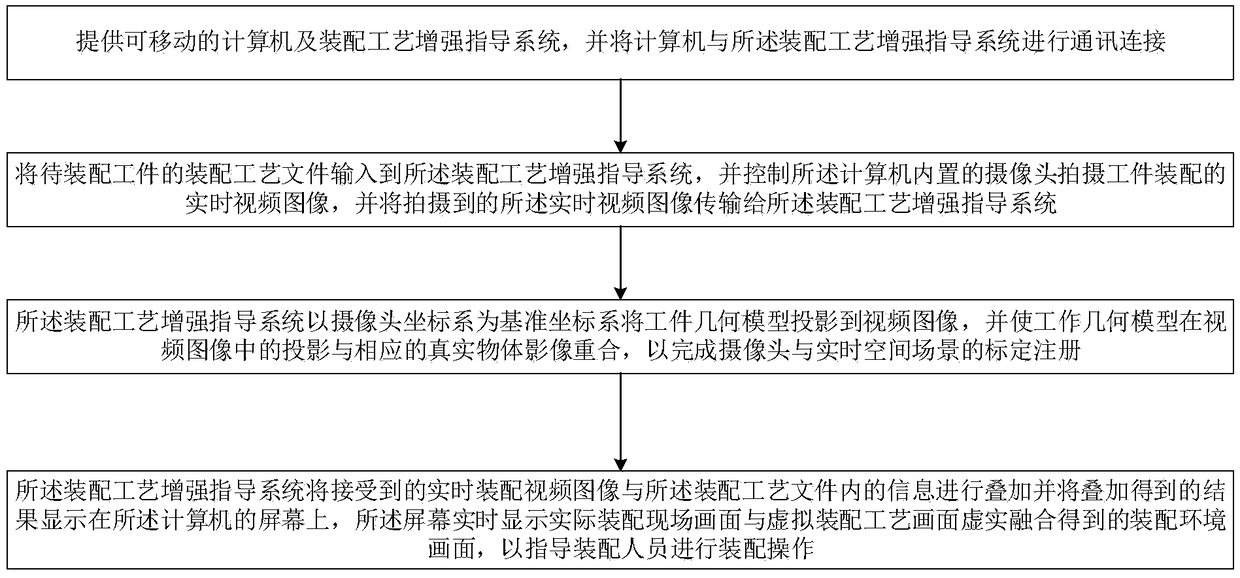

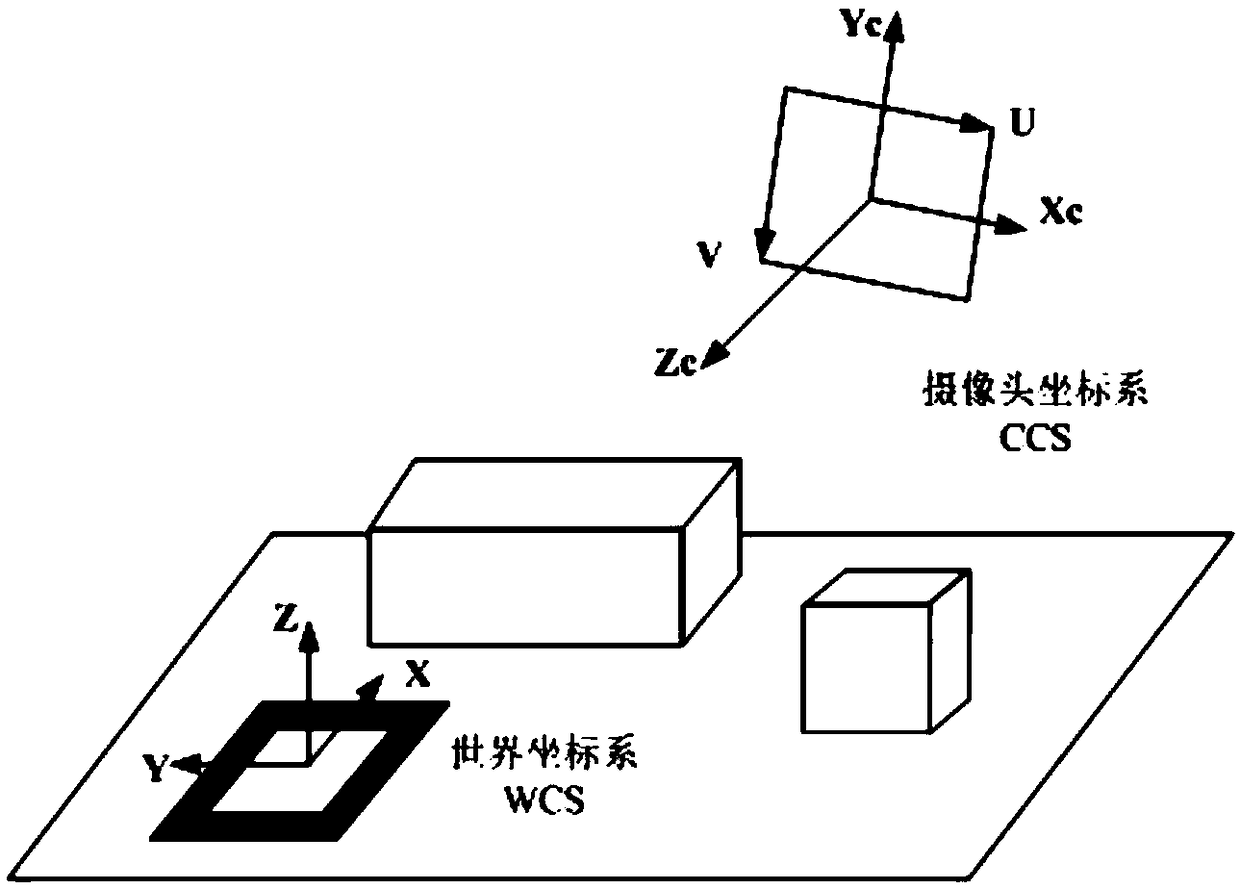

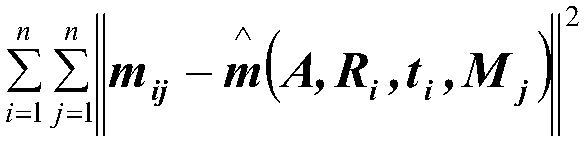

An augmented reality guidance method for a product assembly process based on mobile computer

InactiveCN109189213AMeet mobileMeet Assembly Enhancement Guidance RequirementsInput/output for user-computer interactionCosmonautic condition simulationsGuidance systemComputer graphics (images)

The invention belongs to the technical field related to product assembly, and discloses an augmented reality guidance method for a product assembly process based on mobile computer. The method comprises the following steps: (1) providing a mobile computer and an assembly process augmented guidance system, and communicatively connecting the mobile computer and the assembly process augmented guidance system; (2) inputting the assembly process file of the workpiece to be assembled into the assembly process augmented guidance system, controlling the camera built in the computer to photograph the real-time video image of the workpiece assembly, and transmitting the photographed real-time video image to the assembly process augmented guidance system; (3) projecting the geometric model of the workpiece onto the video image based on the camera coordinate system, and making the projection of the geometric model of workpiece in the video image coincide with the corresponding real object image, so as to complete the calibration and registration of the camera and the real-time spatial scene. The method is easy to implement, has good flexibility and shortens time and error rate.

Owner:HUAZHONG UNIV OF SCI & TECH

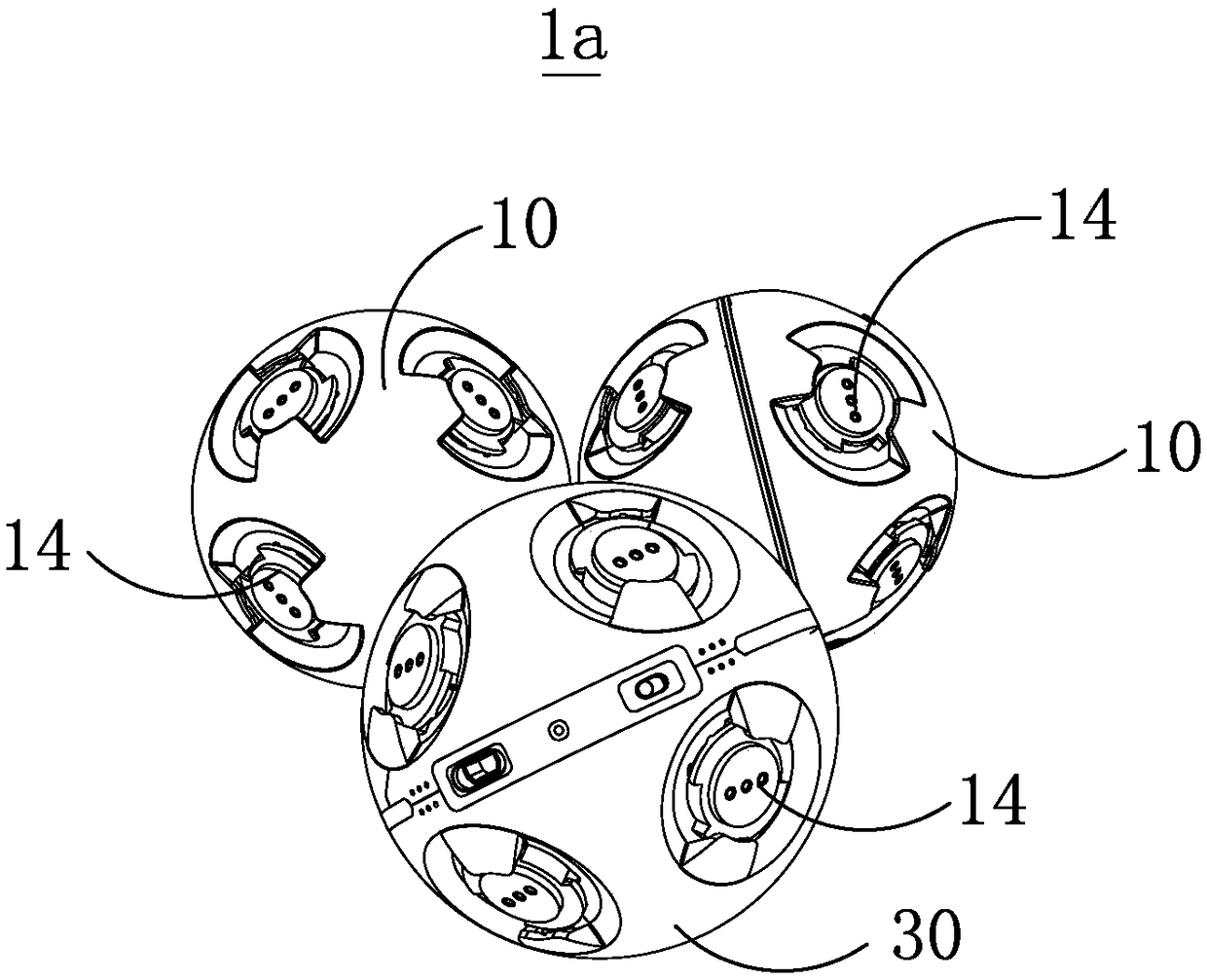

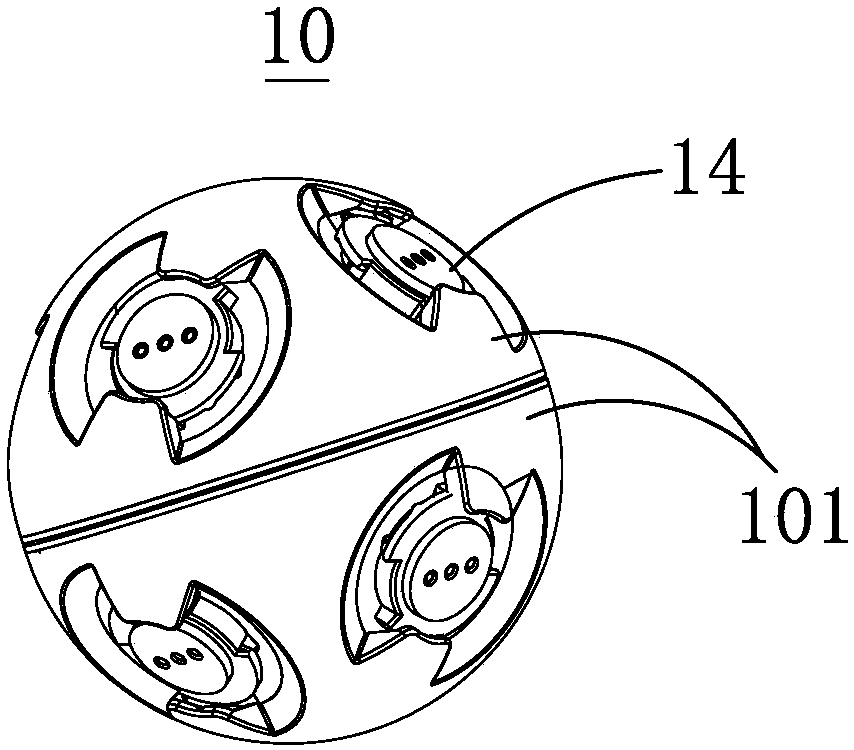

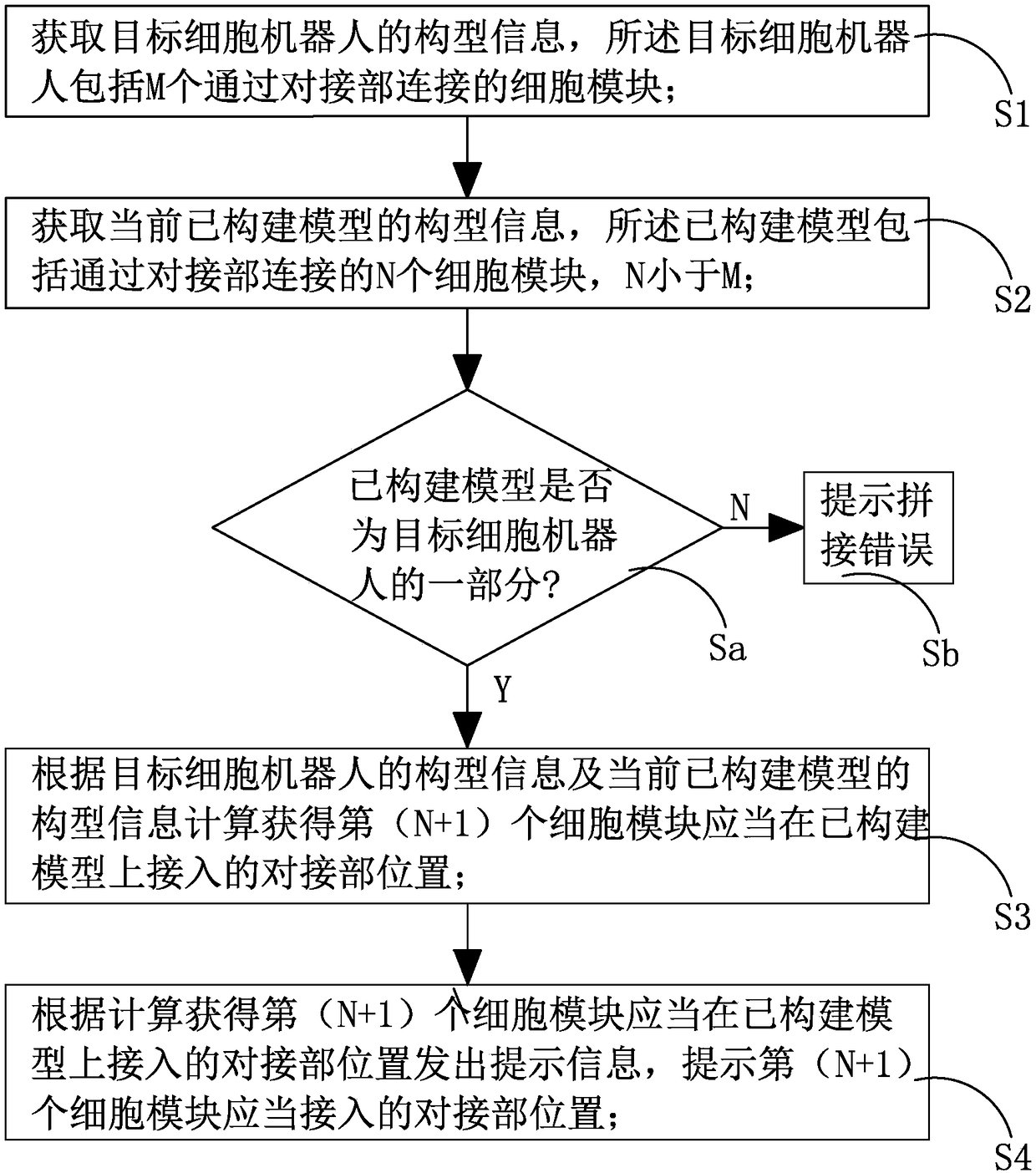

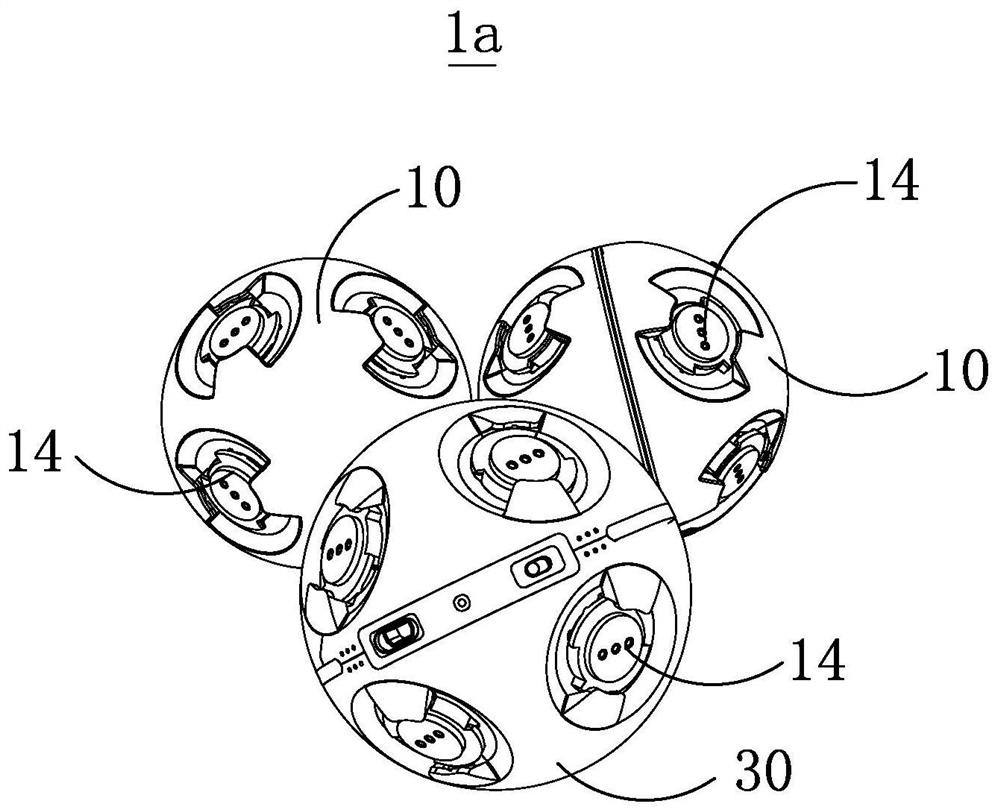

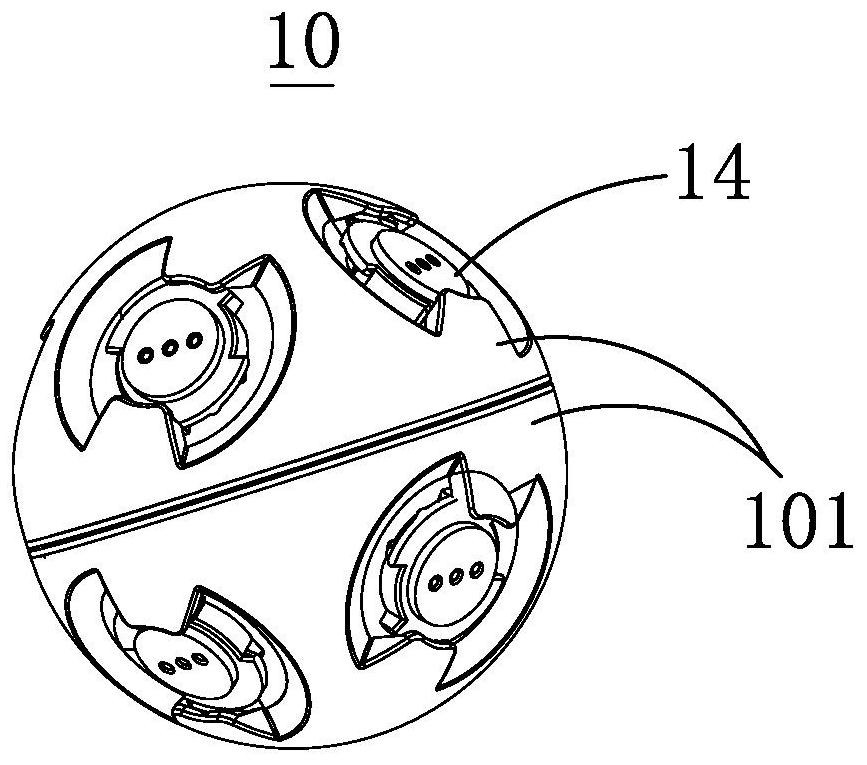

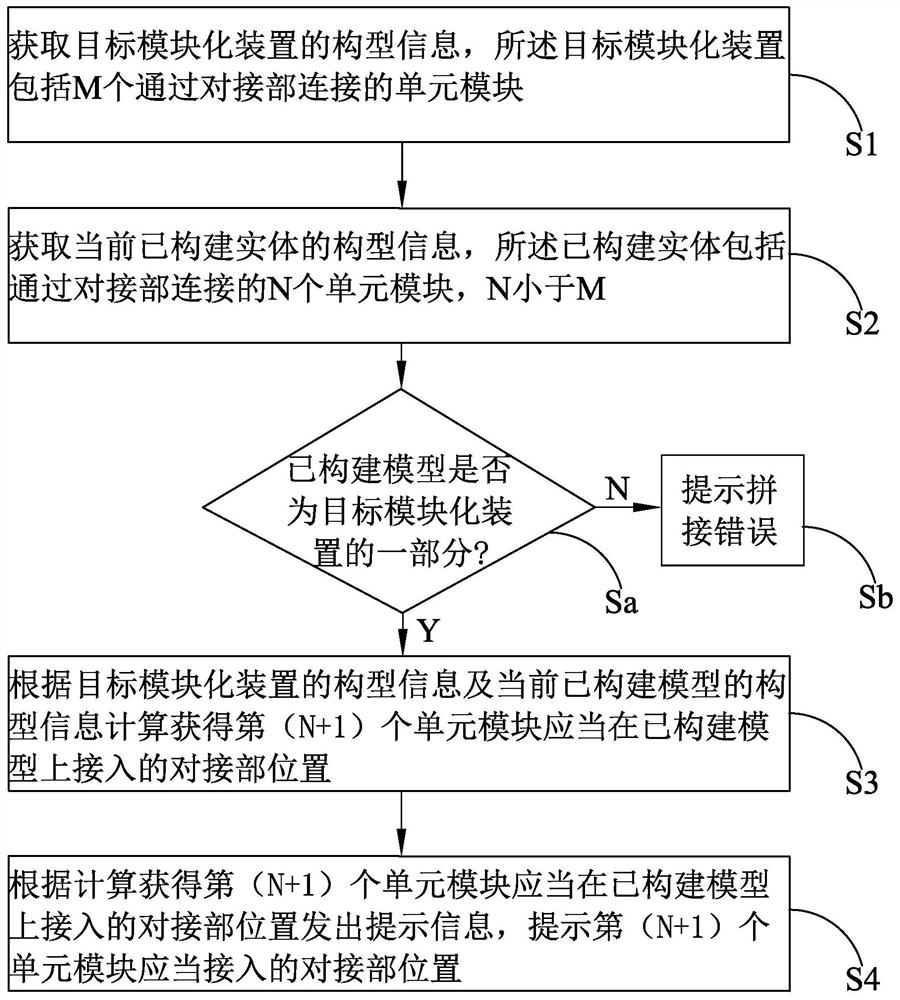

Construction prompting method and system of modular device

ActiveCN108115686AReduce assembly error rateEasy refactoringProgramme controlProgramme-controlled manipulatorModularityConfiguration interaction

The invention provides a construction prompting method and system of a modular device. The method includes steps: S1, acquiring configuration information of a target modular device which comprises M unit modules connected through a docking portion; S2, acquiring configuration information of a currently built entity which comprises N unit modules connected through a docking portion, wherein N is smaller than M; S3, calculating according to the configuration information of the target modular device and the configuration information of the currently built entity to acquire a position, at which the (N+1)th unit module should be connected in the currently built entity, of the docking portion at least; S4, sending prompting information according to the position acquired in the S3 to prompt the position. By adopting the construction prompting method and system, reconstruction splicing errors of the modular device can be reduced.

Owner:BEIJING KEYI TECH

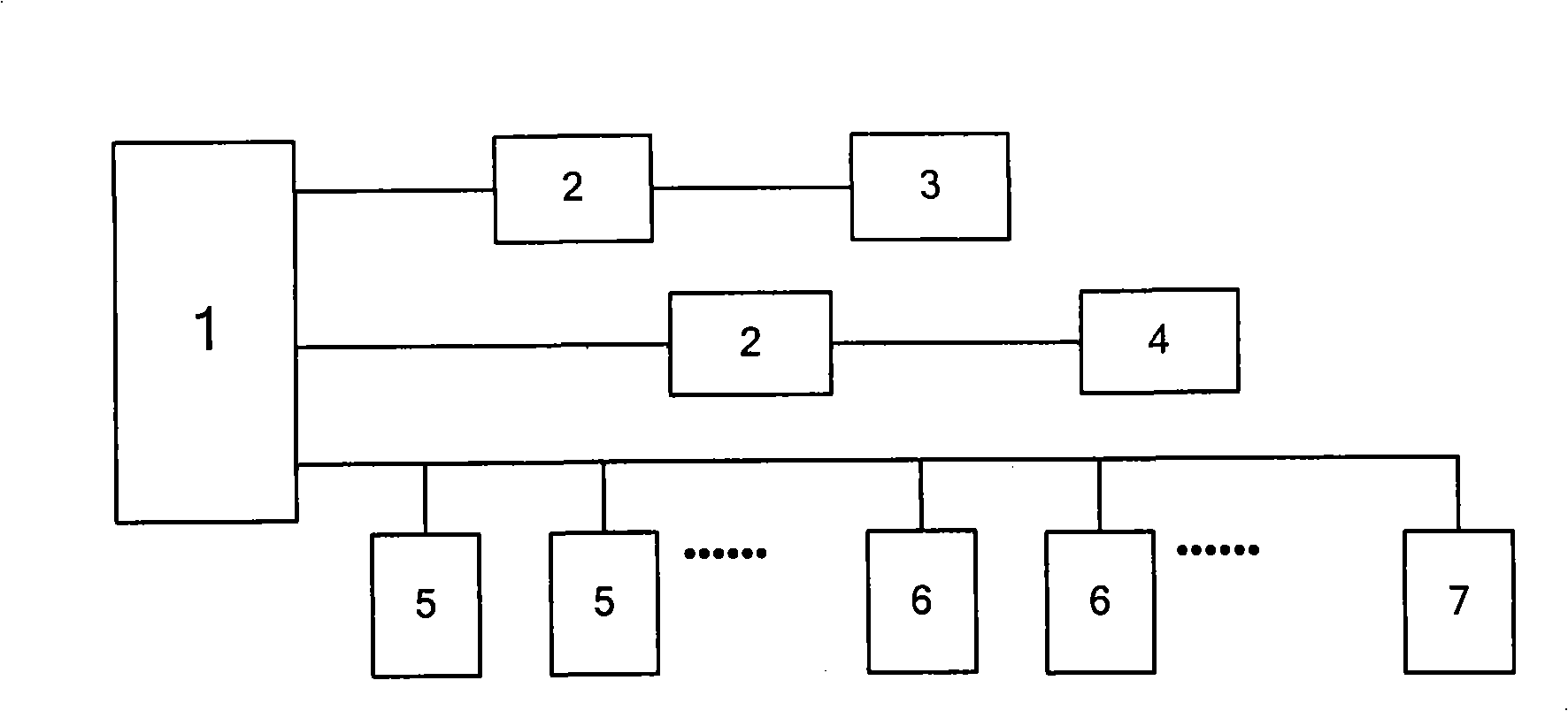

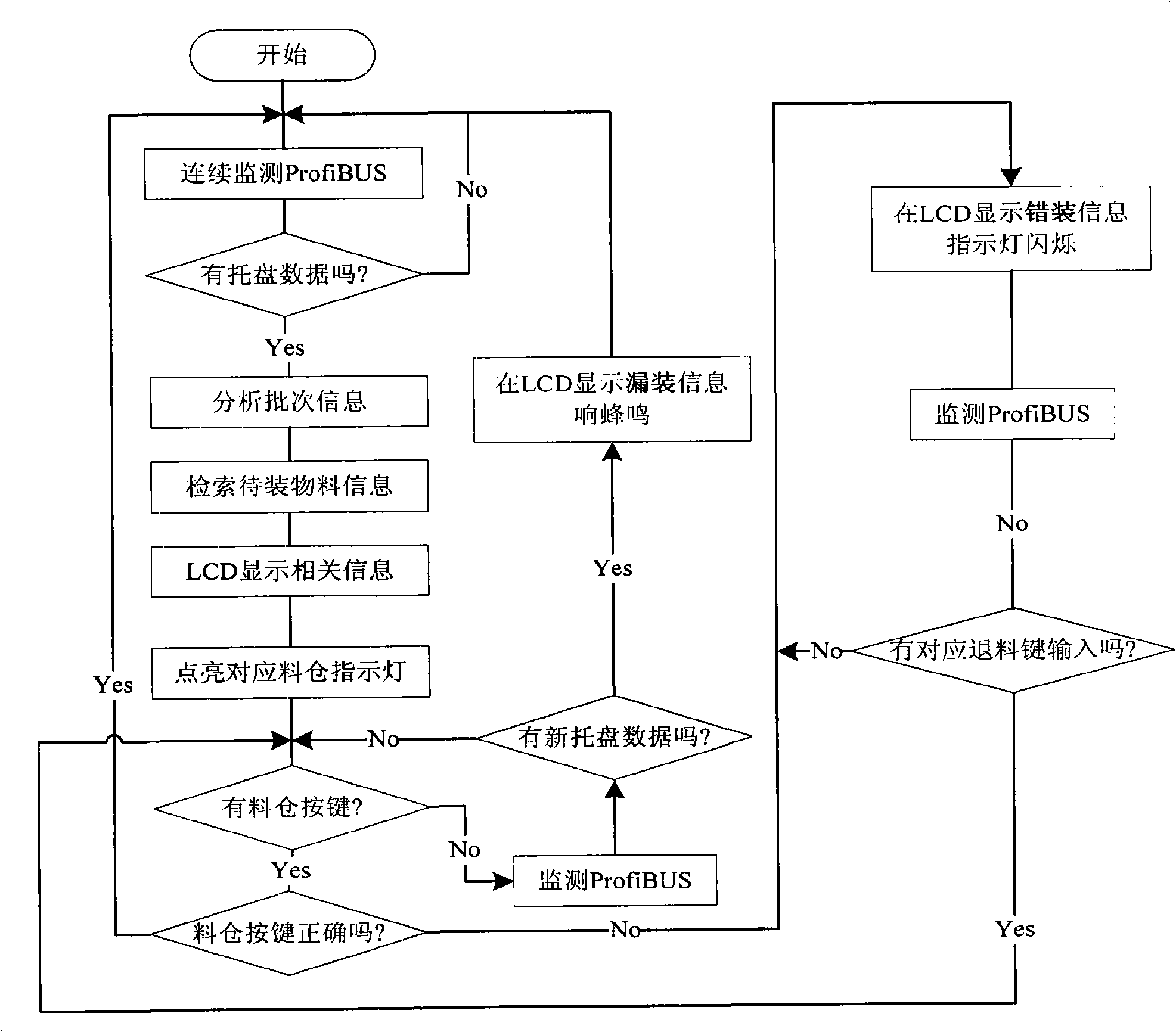

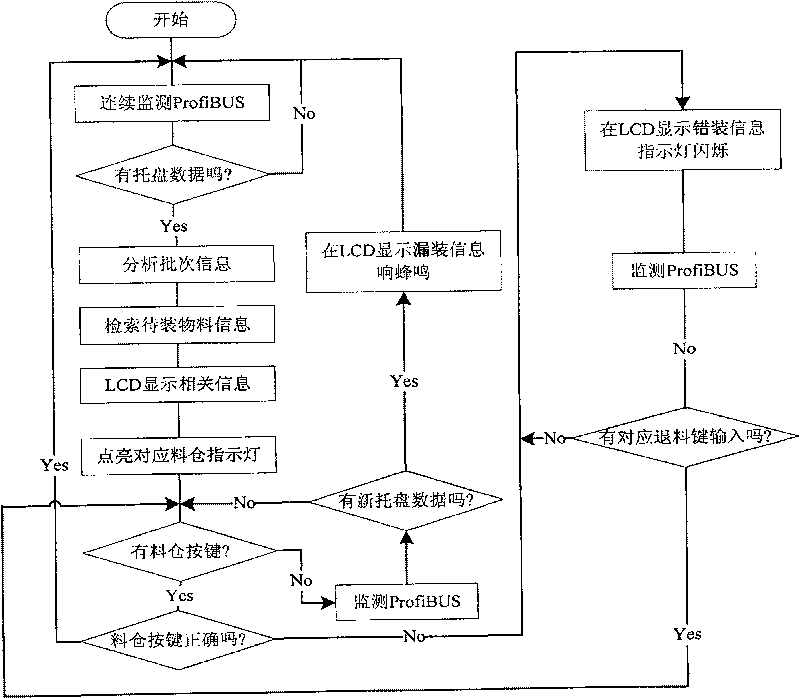

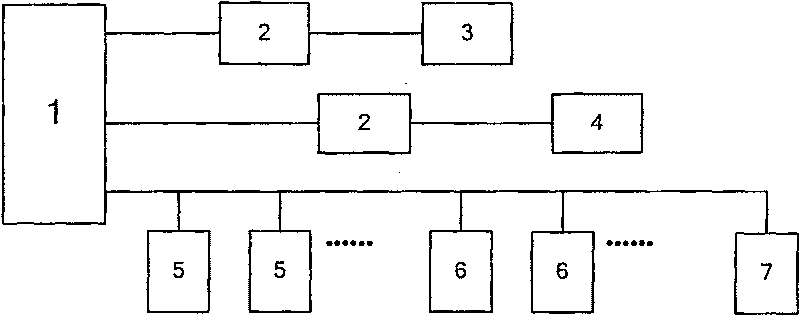

Mixed flow assembly line intelligent material gallow device possessing visualized monitoring function

InactiveCN101308367AInstructions are accurateReduce assembly error rateProgramme controlComputer controlManufacturing cost reductionVisual technology

The invention belongs to the mixed-model assembly line material management and assembly monitoring technology, relating to a mixed-model assembly line smart rack device with visual monitoring function. The device is composed of a single chip, a bus interface, a RFID reader, an assembly display screen, indicator lights, assembly buttons and buzzers; wherein, the single chip is connected with a plurality of indicator lights, assembly buttons and a buzzer. The RFID reader and the assembly display screen are respectively connected with the single chip through the bus interface to form a serial communication mode with the single chip. The invention uses the data acquisition real-time and visual technology to manage and monitor the mixed-model assembly process and can reduce the error rate in engine assembly, improve product quality and work efficiency, as well as reduce manufacturing costs.

Owner:HUAZHONG UNIV OF SCI & TECH

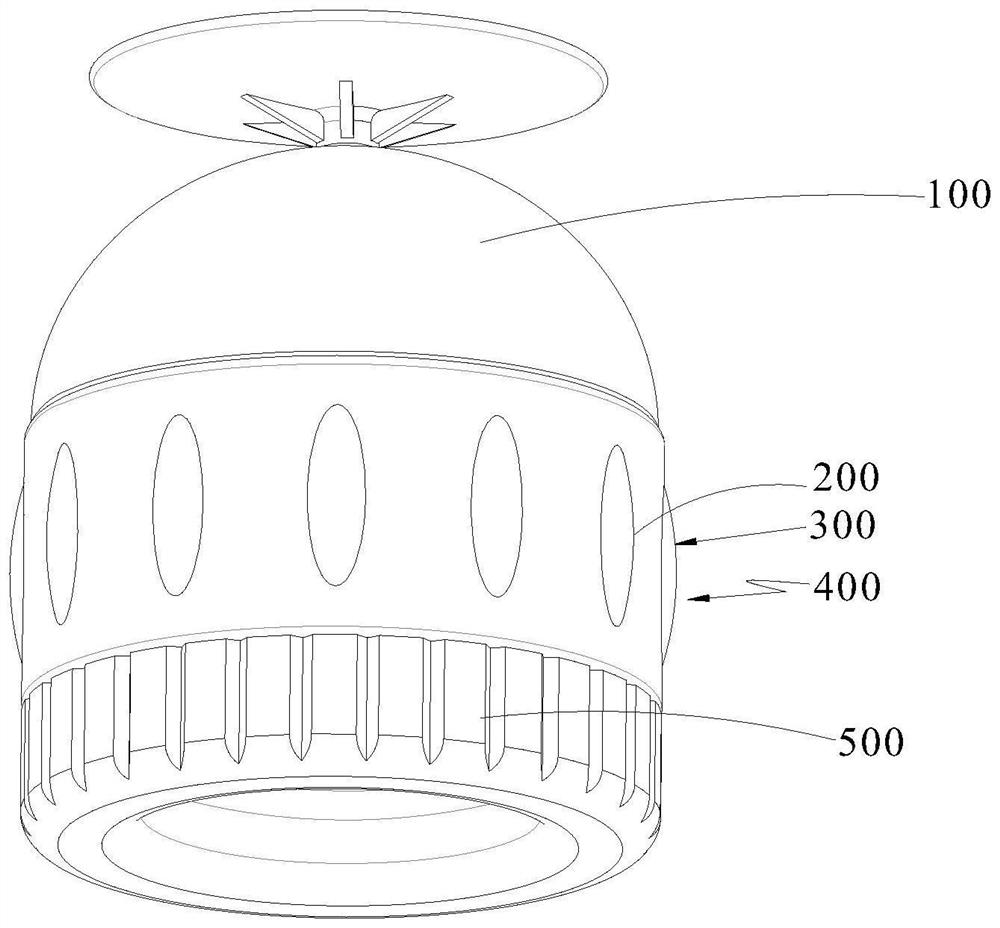

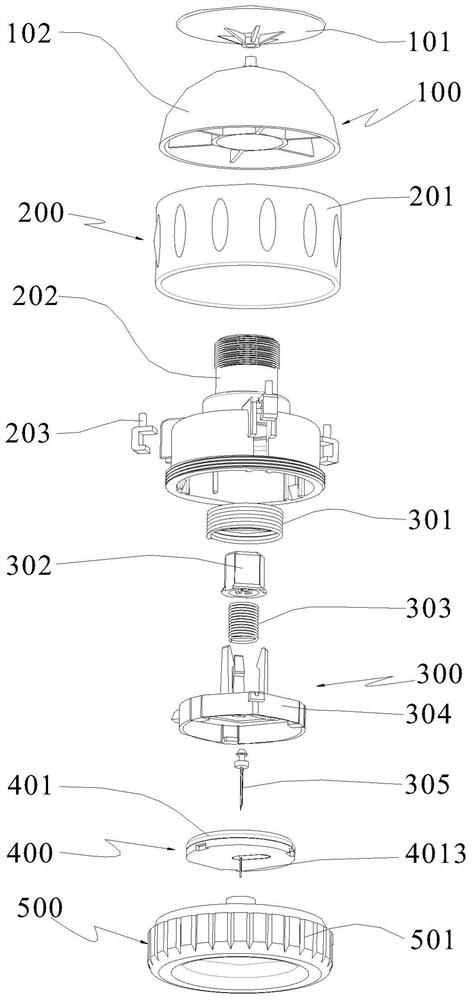

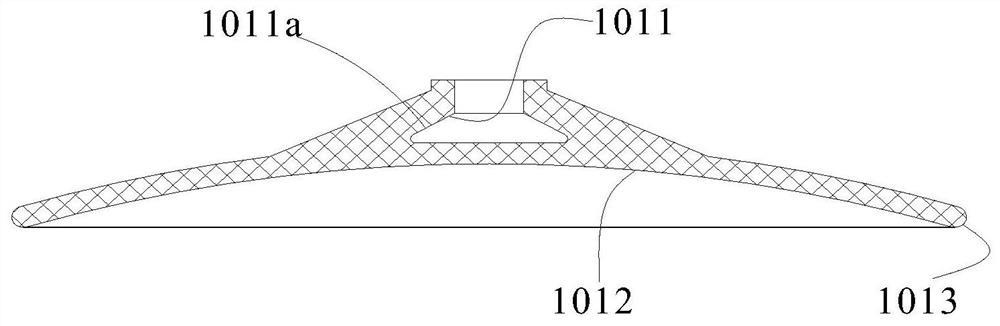

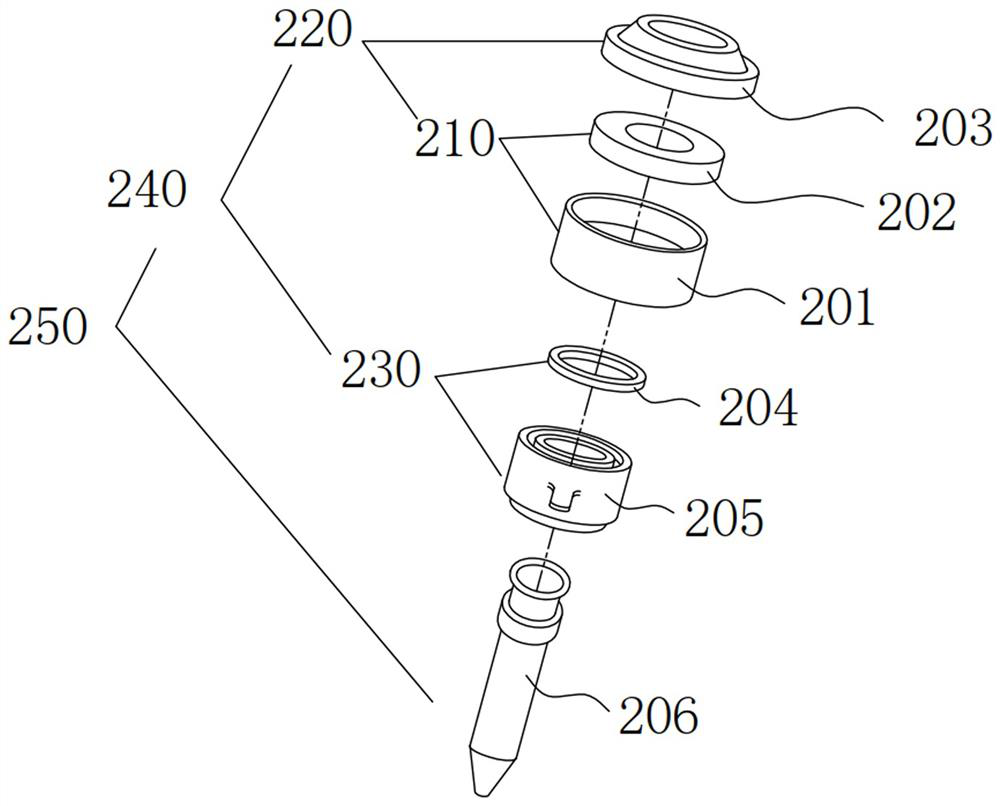

Adsorption knob needle assisting device

The invention discloses an adsorption knob needle assisting device. The adsorption knob needle assisting device comprises an emitter module, a percussion module and a trigger module, wherein the emitter module comprises a sensor capable of remaining in a human body; the percussion module is associated with the emitter module and is used for pushing the sensor to be inserted into the human body; and the trigger module is associated with the percussion module to start the percussion module. According to the integrated continuous blood glucose detection instrument, the sensor implanting operation can be completed only by rotating an outer shell, the sensor implanting step is simplified, and the assembly error rate is reduced; and meanwhile, the sensor can be implanted by using a higher pair connection structure and rotating a percussion knob with a single hand, so that the triggering sensitivity and stability and the operation comfort of a user are improved.

Owner:VIVACHEK BIOTECH HANGZHOU

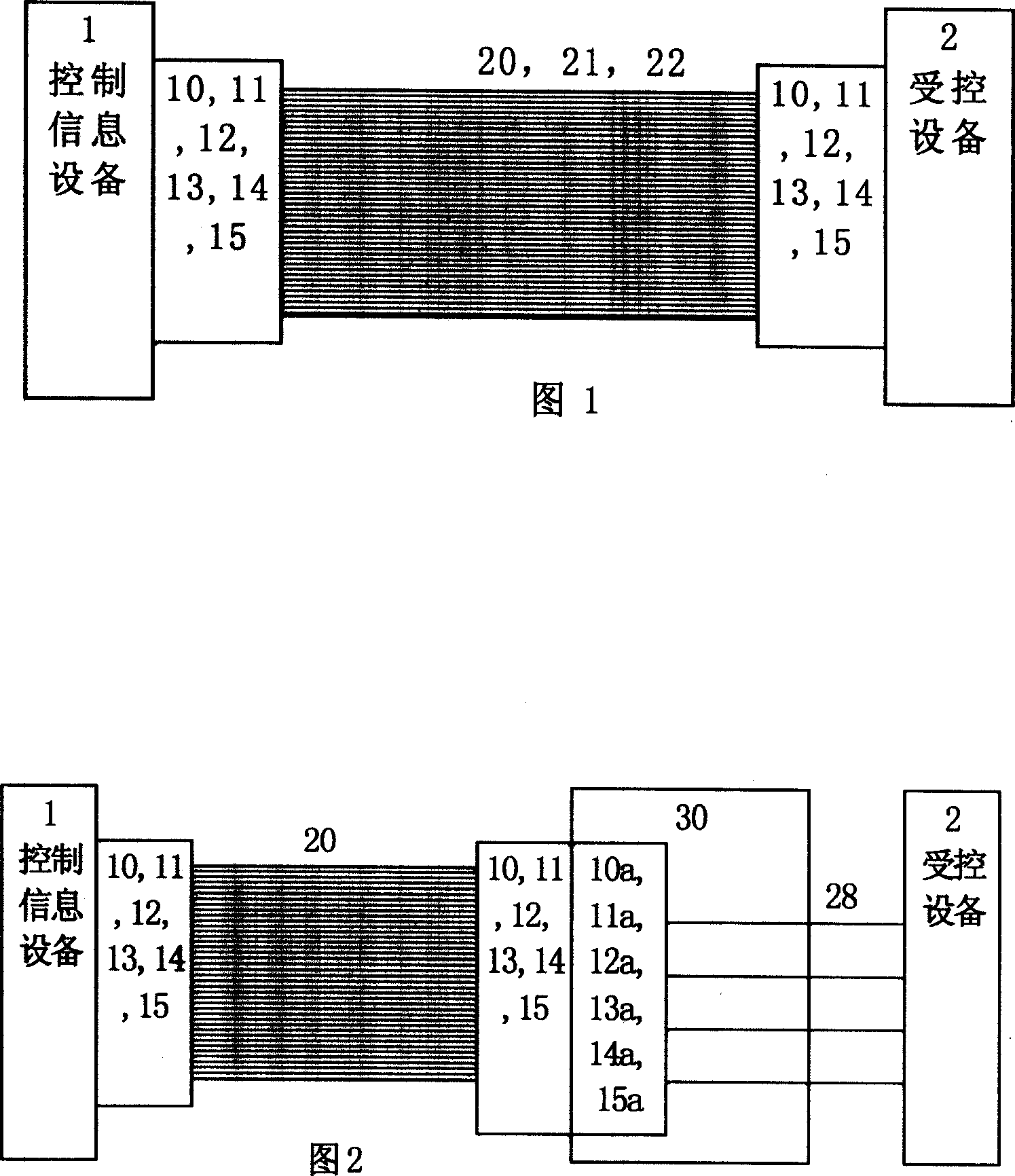

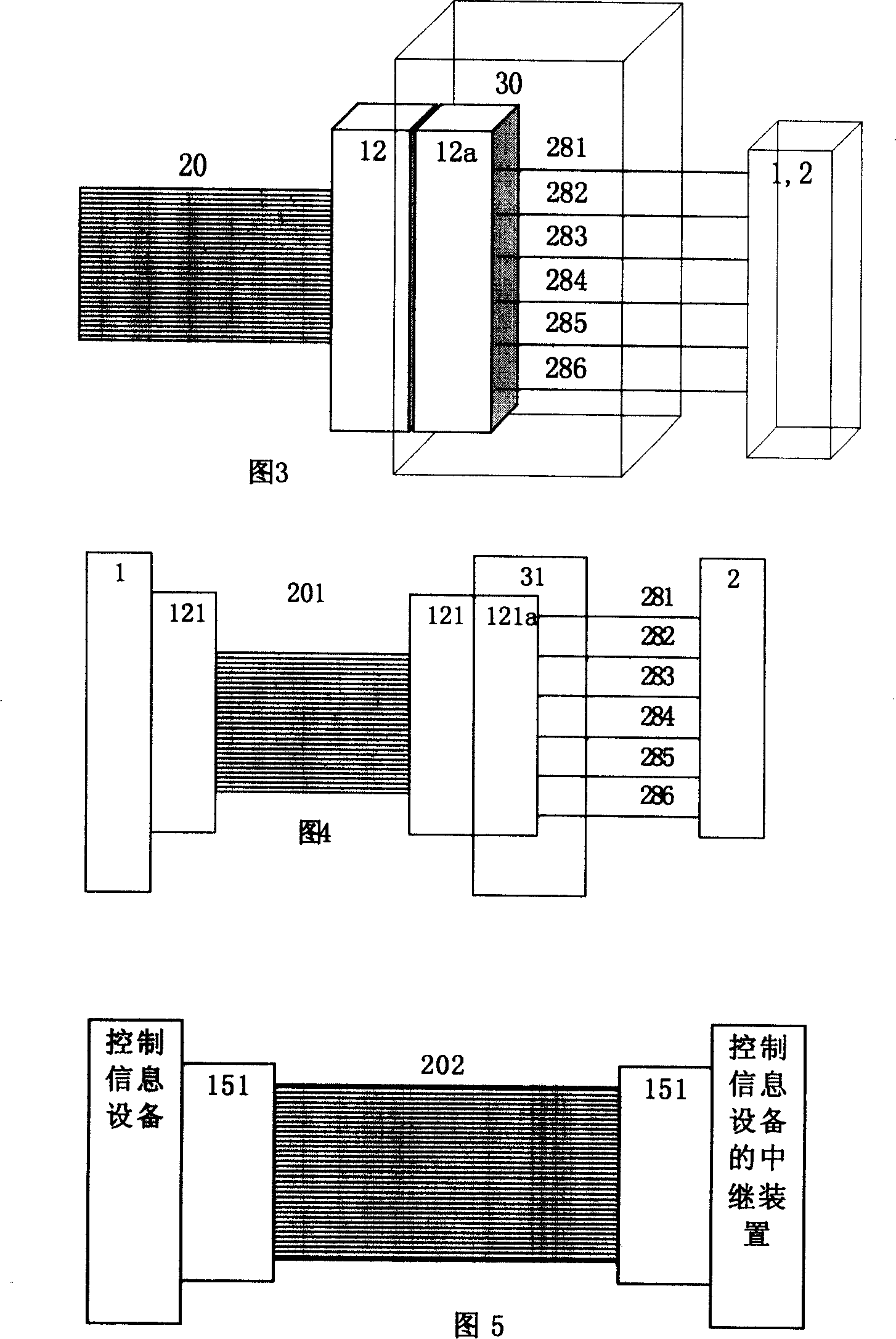

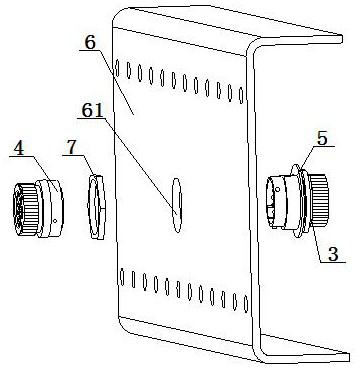

Connecting method for equipment in building energy-saving control system and adapter

InactiveCN101090187AReliable crimping designIncrease production capacityCoupling device connectionsMulticore cableControl system

This invention provides a connecting method among devices in a building energy-save control system characterizing in applying standard plugs and sockets and multi-core cables between any two devices in the system. In order to implement this invention, standardized connection can be realized to the existent product devices without standard sockets by connection conversion boxes provided by this invention, and the output of the box includes a standard multi-core socket corresponding to standard plugs and the input includes connection end of leading out wire corresponding to the non-standard connection to be connected with the standard cable by the conversion box.

Owner:四川百事泰能源科技有限公司

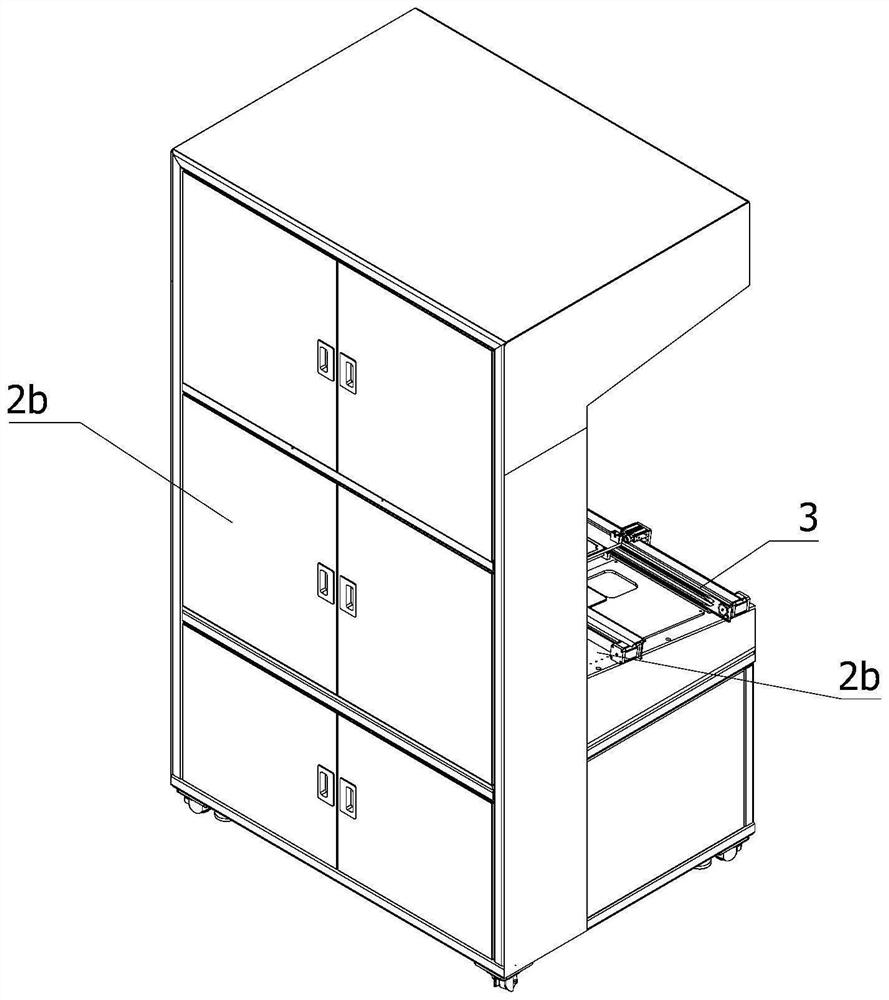

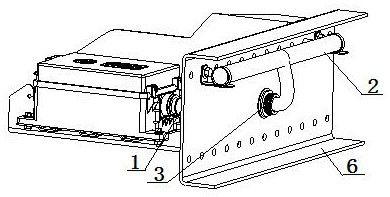

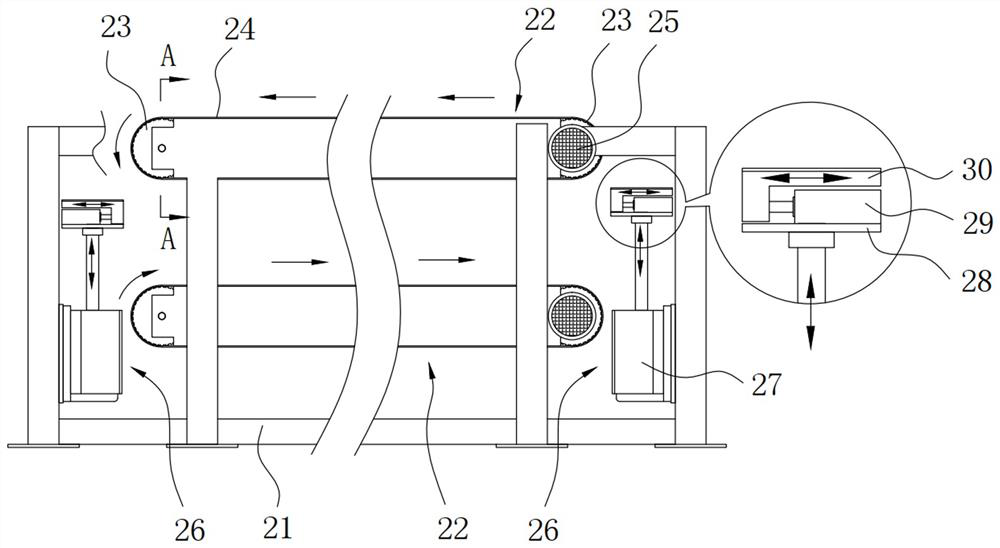

PCB plug-in feeding system for guiding installation through utilizing laser

ActiveCN113939179AReduce assembly error rateLower operating thresholdElectrical componentsConveyor partsLaser transmitterElectric control

The invention relates to the field of PCB plug-in assembly, in particular to a PCB plug-in feeding system for guiding installation through utilizing laser. The PCB plug-in feeding system comprises a PCB, and further comprises a rack, a positioning and installing mechanism, a laser guiding mechanism, a feeding mechanism, a material taking mechanism and an electric control system, wherein an inclined operation platform is arranged in the middle of the rack, the positioning and installing mechanism comprises a PCB carrier platform, the laser guiding mechanism is arranged at the top end of the rack, the laser guide mechanism is provided with a laser emitter capable of freely moving in the X-axis direction and the Y-axis direction, the feeding mechanism comprises a plurality of material supply boxes capable of freely moving in the X-axis direction and the Y-axis direction, and the positioning and installing mechanism, the laser guiding mechanism, the feeding mechanism and the material taking mechanism are all electrically connected with the electric control system. According to the PCB plug-in feeding system, a laser designator, a linkage mechanical conveying device and an intelligent material supplementing system are utilized, materials needed by laser indication are automatically supplied, the probability of wrong insertion is completely eradicated, the production efficiency is improved, the pre-warning material supplementing function is achieved, and lean production is achieved.

Owner:GUANGZHOU PANYU TRIO MICROTRONIC

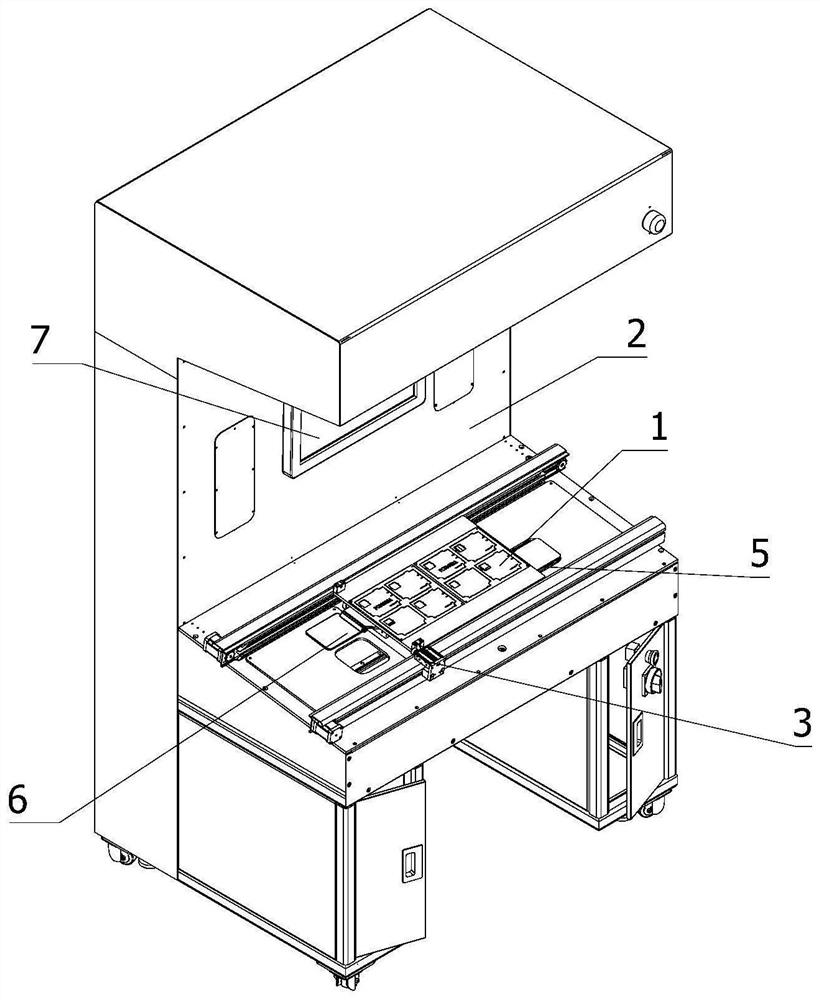

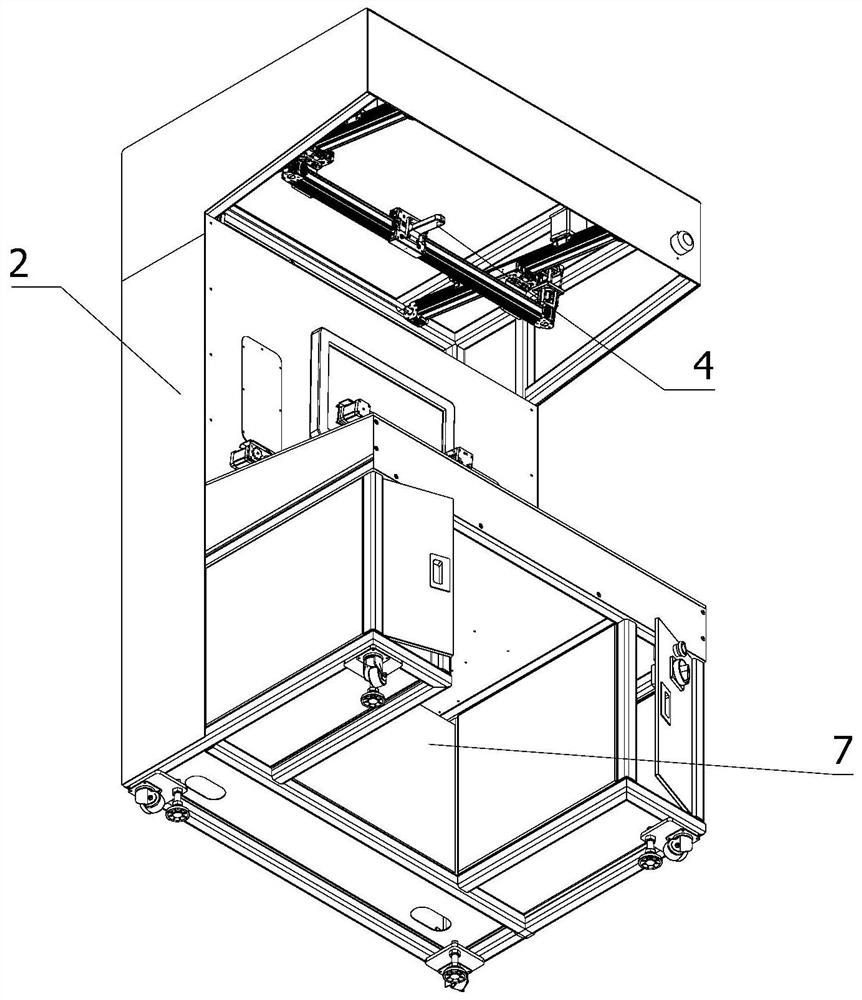

Assembling equipment used for large-diameter projection lens

PendingCN109383035APerfect assembly equipmentLower assembly costsOptical articlesManipulatorEquipment use

The invention relates to an assembling equipment used for large-diameter projection lens. The assembling equipment used for large-diameter projection lens comprises a machine installing housing; a dustproof protection cabin, a computer controller, a hot melting mechanism, a centering mechanism, a mechanical arm assembling mechanism, and a material changing mechanism are arranged in the machine installing housing; the computer controller is connected with the hot melting mechanism, the centering mechanism, the mechanical arm assembling mechanism, and the material changing mechanism respectviely; the top end of the machine installing housing is provided with an air purifying filtering device and an alarm light. The advantages are that: the assembling equipment can be used for assembling of large-diameter projection lens, filling the market blank of large-diameter projection lens assembling, improving projection lens assembling equipment, realizing large diameter projection lens assembling mechanical automation process, reducing assembling cost, assembling error rate, and requirement on worker quality, reducing assembling cost, and realizing large batch large diameter projection lensassembling.

Owner:JIANGSU YUDI OPTICAL CO LTD

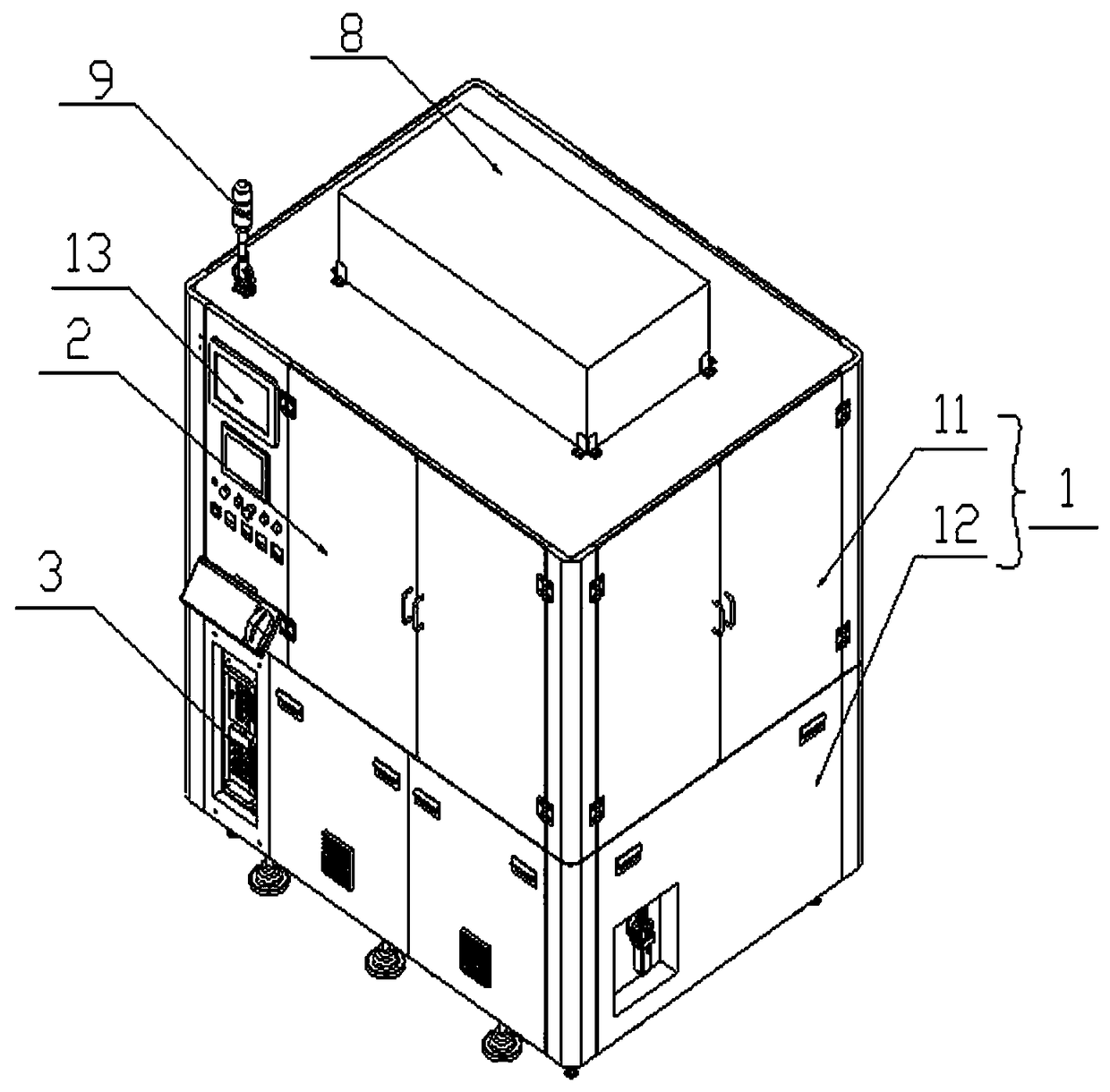

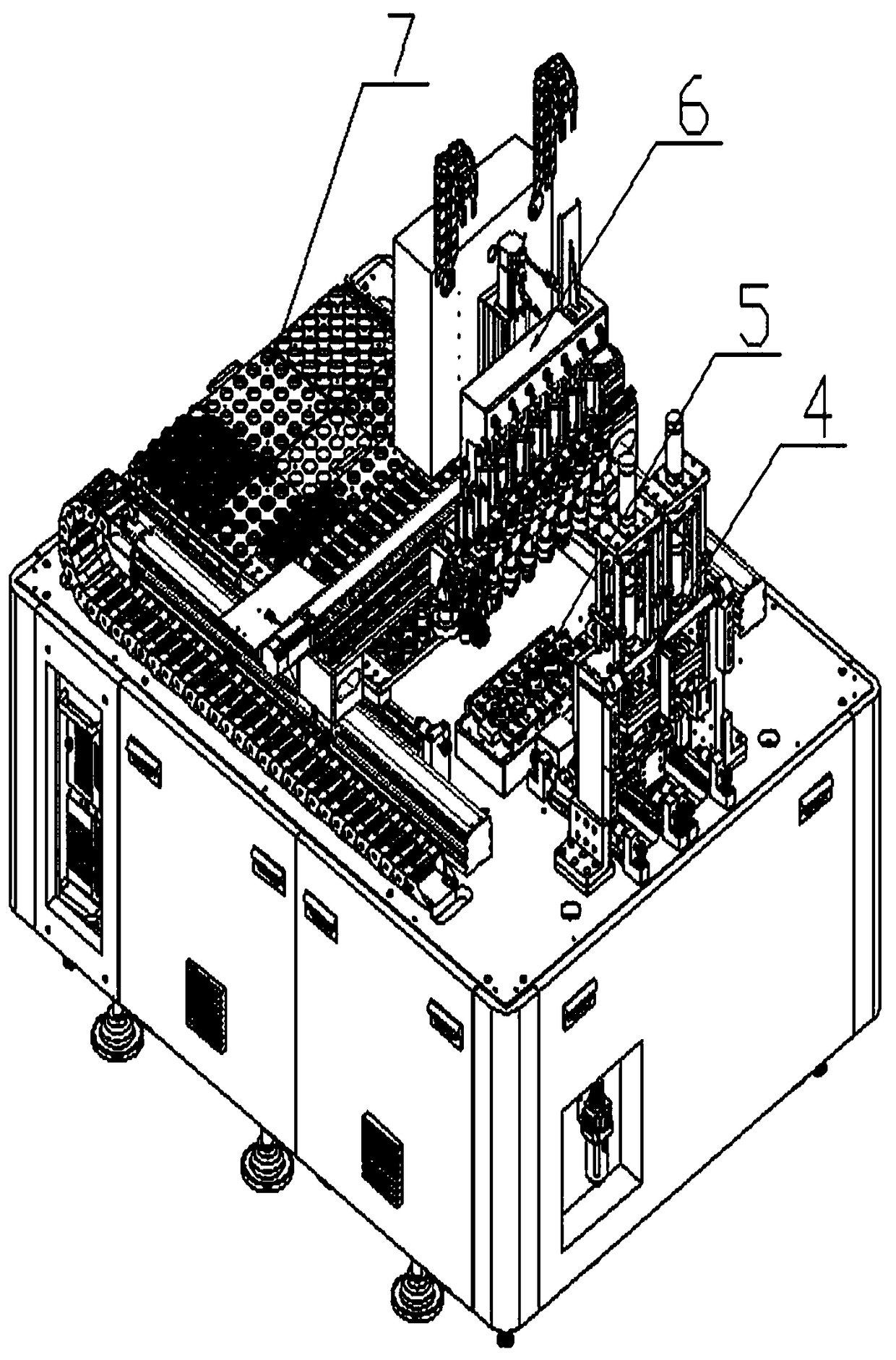

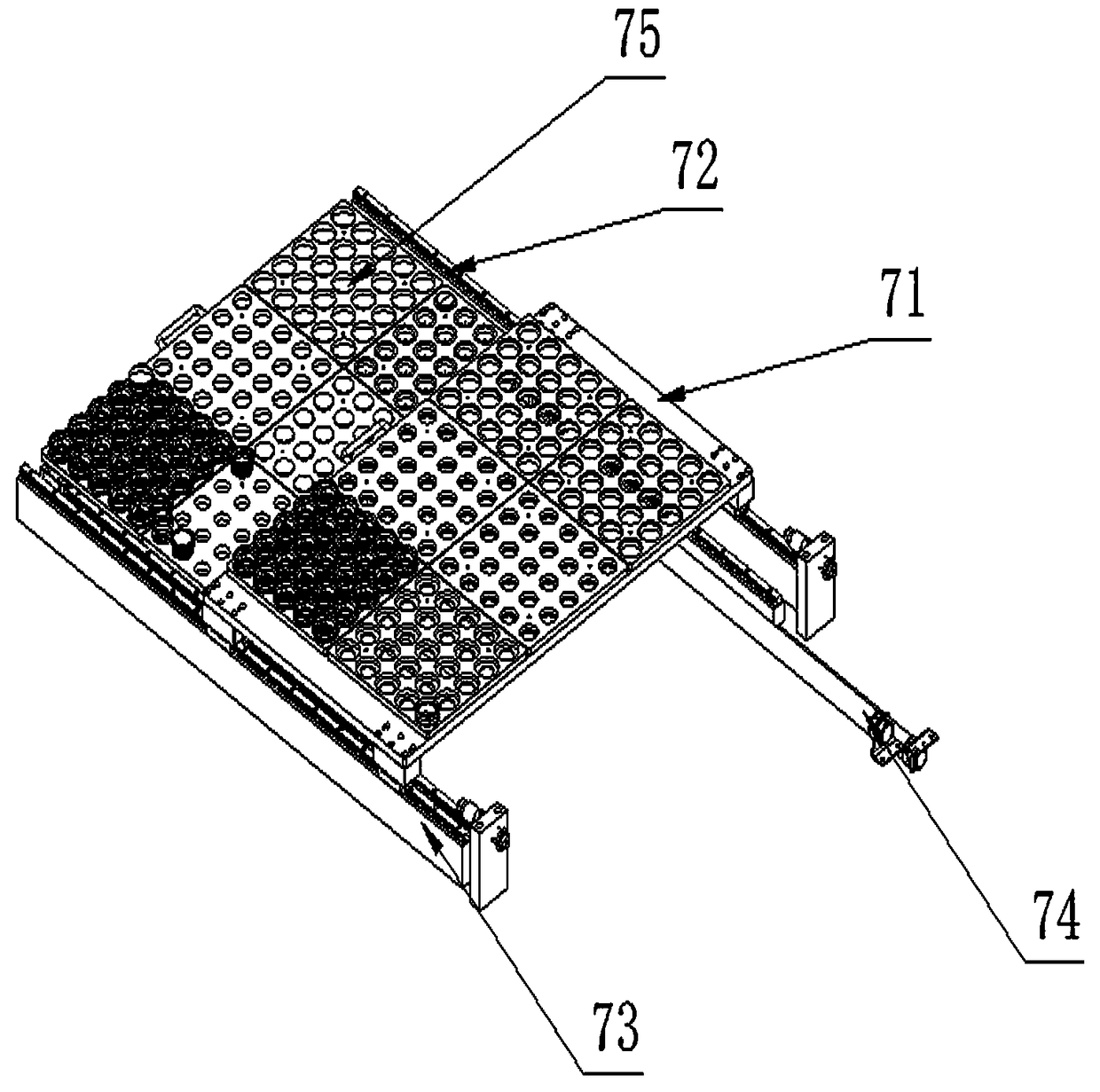

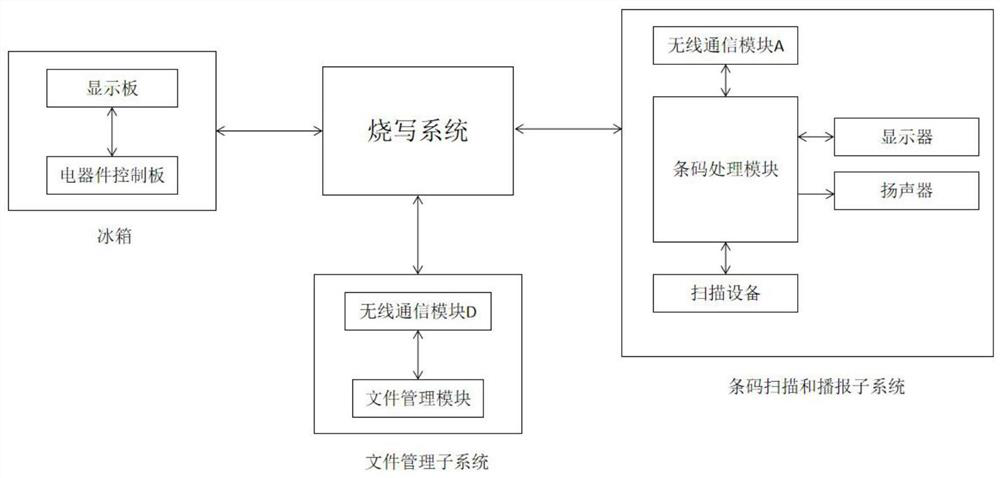

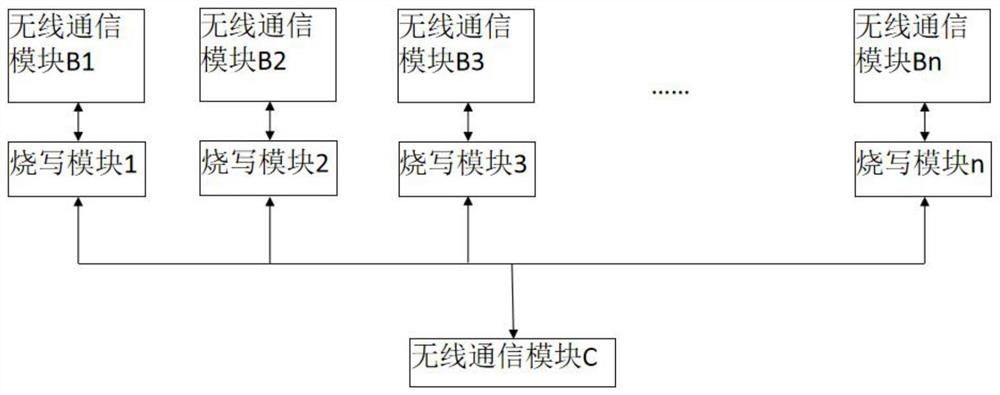

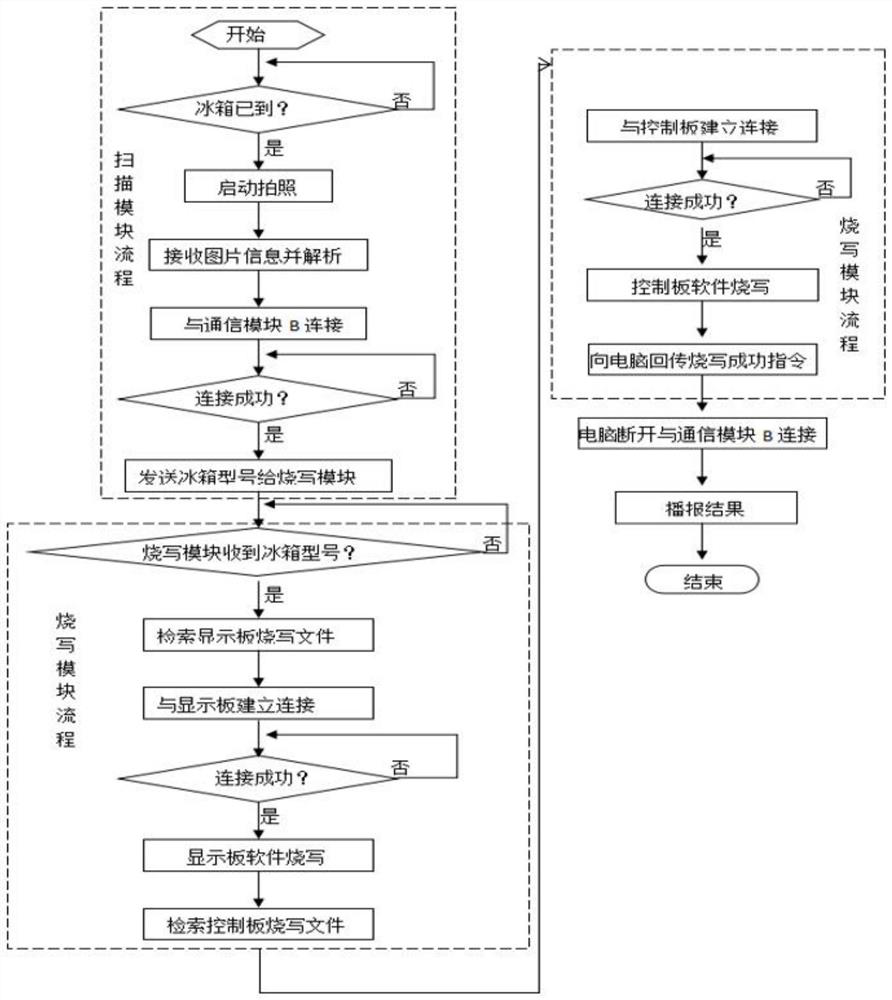

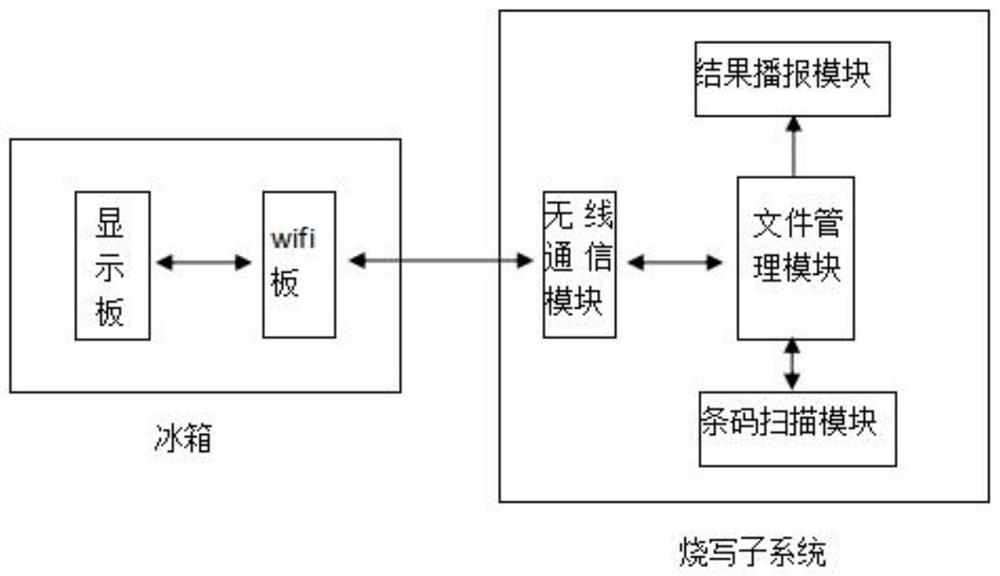

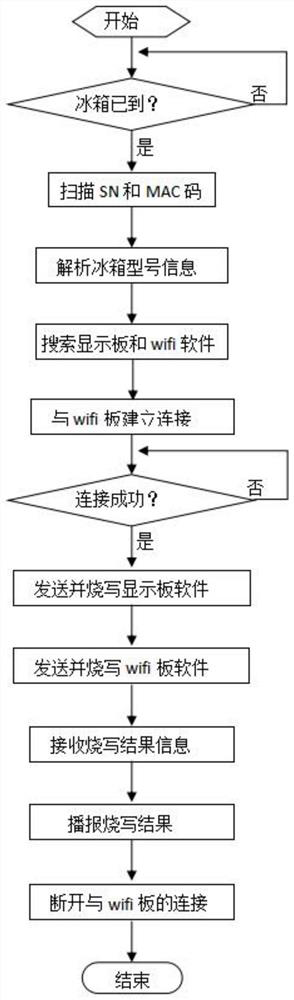

Online programming system for refrigerator control software

InactiveCN111913726AReduce management costsReduce assembly error rateDigital data information retrievalTransmission systemsDisplay boardIcebox

The invention discloses an online programming system for refrigerator control software, and relates to the technical field of refrigerator production and assembly. The system comprises a refrigeratorelectric control subsystem, a programming subsystem, a bar code scanning and broadcasting subsystem and a file management subsystem. The refrigerator electric control subsystem comprises a display panel and an electric device control panel. The programming subsystem comprises a plurality of programming units and a wireless communication module C; and the file management subsystem comprises a filemanagement module and a wireless communication module D. The SN number on the refrigerator is scanned through the bar code scanning device, the bar code analysis module analyzes the information of therefrigerator and then sends the information to the software programming module, the software programming module retrieves programming software of the refrigerator display panel and the electric device control panel from the database to conduct software programming on the display panel, the material number of the control panel is reduced, the material management cost and the assembly error rate ofthe refrigerator control panel are reduced, and the universalization degree of product materials is improved.

Owner:合肥美菱物联科技有限公司

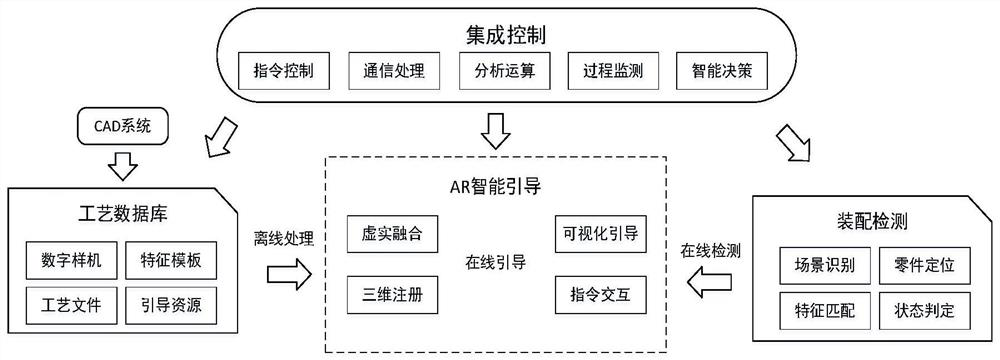

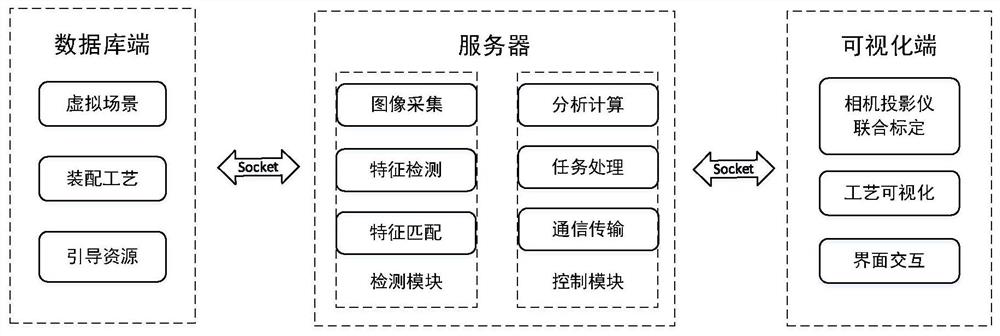

AR fastener auxiliary assembly system and method based on projection display

ActiveCN113220121AImprove manual assembly efficiencyReduce assembly error rateInput/output for user-computer interactionData processing applicationsVisualizationEngineering

The invention discloses an AR fastener auxiliary assembly system and method based on projection display. The AR fastener auxiliary assembly system comprises a process database module, an AR intelligent guide module, an assembly detection module and an integrated control module. An abstract assembly guidance process is projected on an assembly operation site in an AR visualization mode, and an assembly result is detected and fed back in real time, so that the cognitive burden of operators is reduced, the assembly efficiency is improved, and the assembly error rate is reduced. According to the system and the method, the complex and abstract fastener assembly process information is subjected to AR visualization through the AR technology of projection display, is seamlessly fused in a physical assembly scene and is briefly and intuitively presented in front of an operator, and the requirements for the cognitive level and experience judgment ability of the assembly operator on the research and reading process are reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

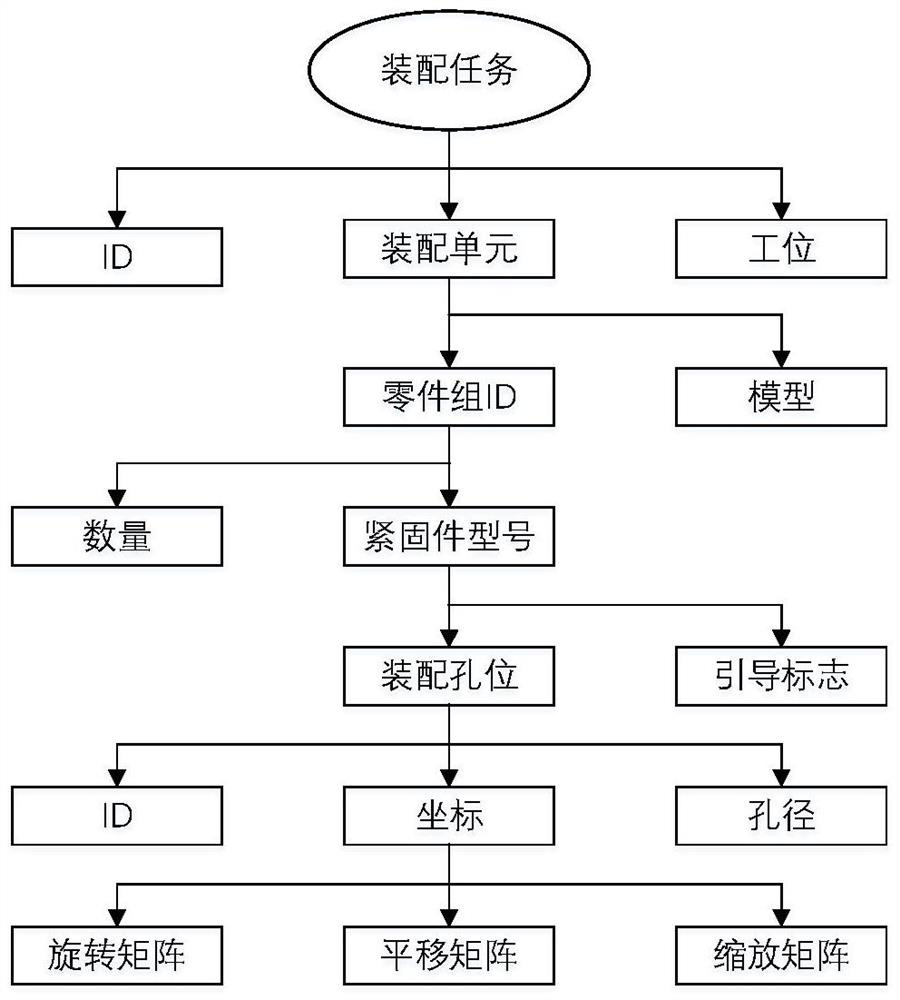

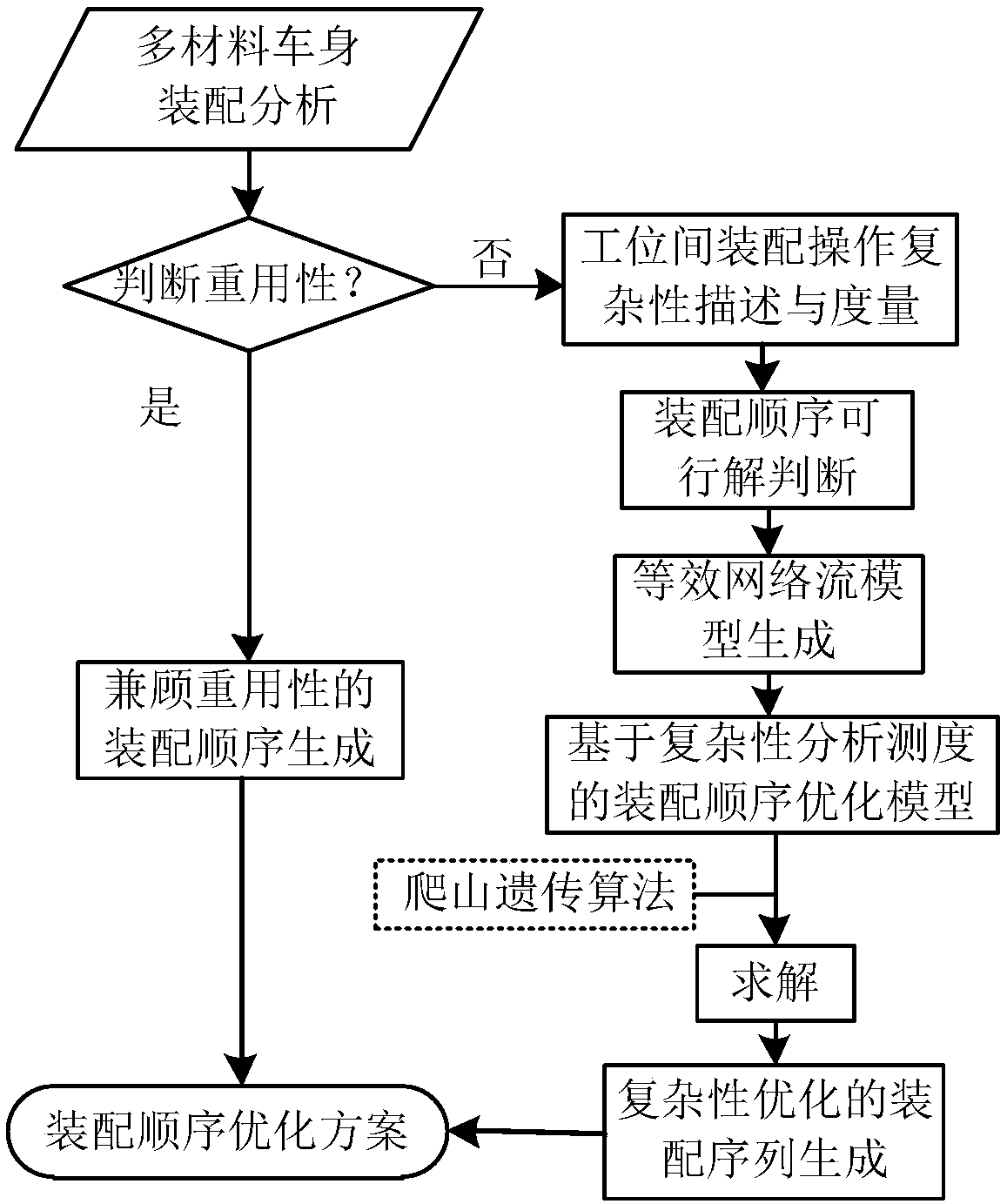

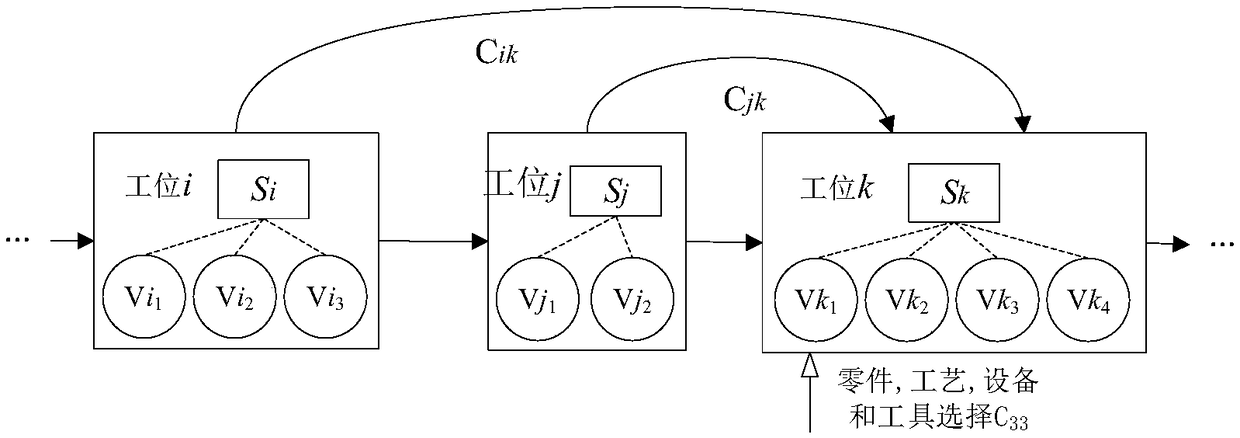

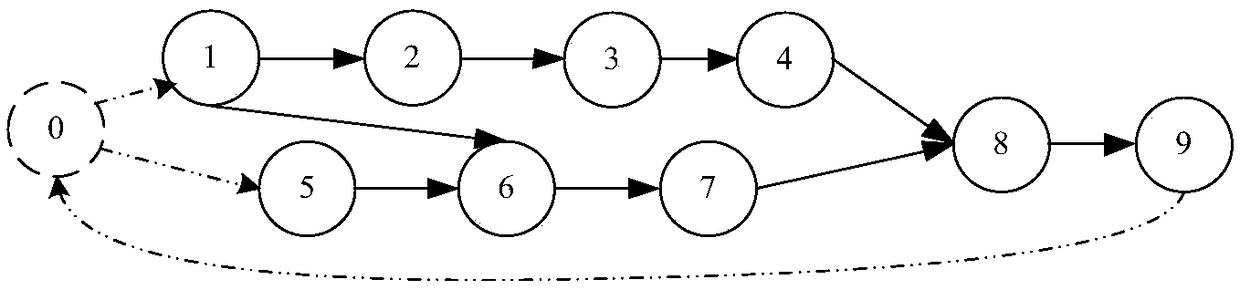

Multi-material car body assembly sequence planning optimization method

ActiveCN108108554AReduce complexityReduce assembly error rateGeometric CADSpecial data processing applicationsMulti materialSequence planning

The invention provides a multi-material car body assembly sequence planning optimization method. Based on a feasible assembly sequence obtained by analyzing car body design assembly information and following multiple constraint relationships among car body assembly parts, and according to description and measurement of station level complexity of multi-material car body assembly nodes, a multi-material lightweight car body assembly sequence planning optimization problem is described by taking conveying complexity as a cost array among the assembly station nodes; a constrained assembly sequenceoptimization problem after removal of invalid information is similar to a constrained non-symmetric traveling salesman problem; an assembly sequence optimization model with a minimum effective conveying complexity sum is built; and the assembly sequence optimization problem is solved by heuristic search elements of a hill climbing genetic algorithm.

Owner:SHANGHAI DIANJI UNIV

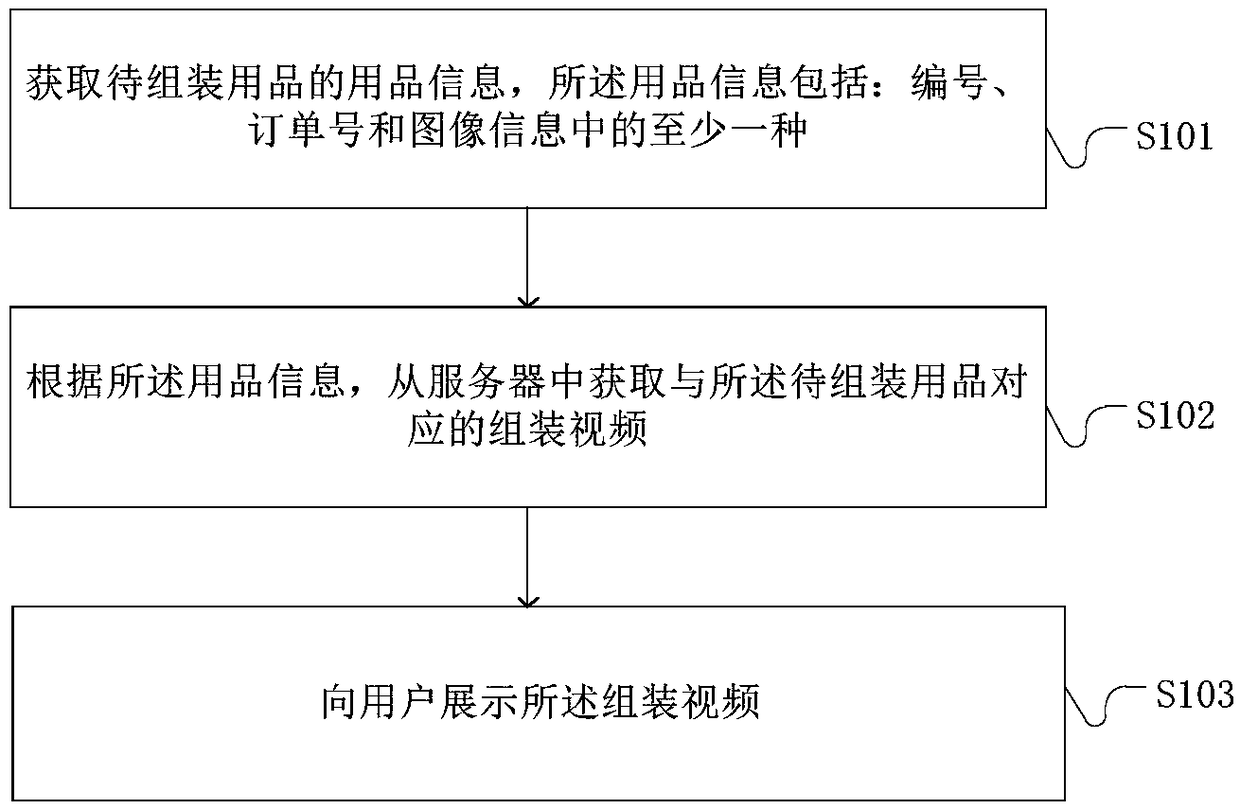

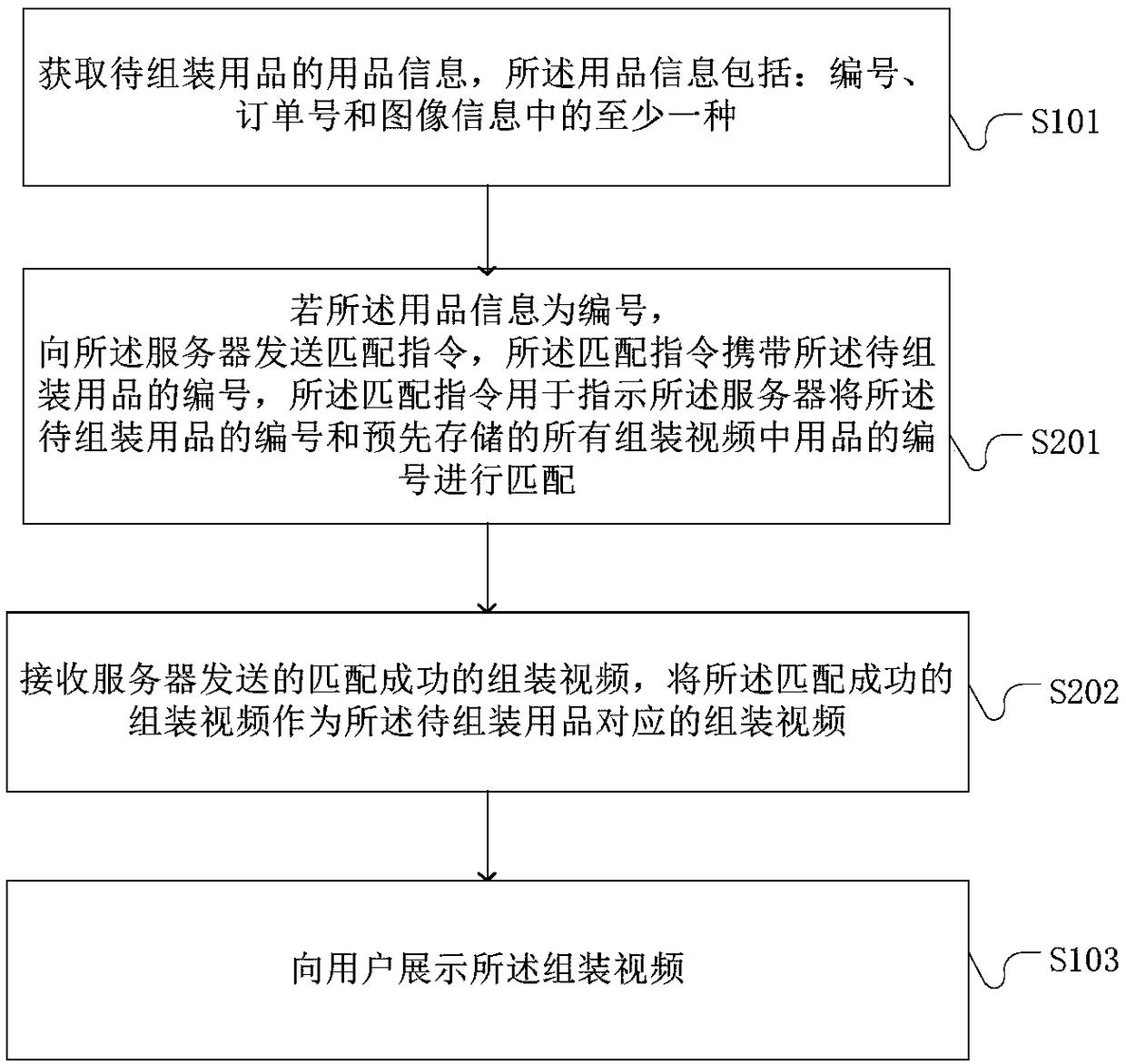

Method and device for determining assembly mode of articles to be assembled

InactiveCN109033417AImprove assembly efficiencyReduce assembly error rateCommerceSpecial data processing applicationsMechanical engineeringSoftware engineering

The invention provides a method and a device for determining an assembly mode of an article to be assembled. The method comprises the following steps of: acquiring article information of an article tobe assembled, wherein the article information comprises at least one of a number, an order number and image information; obtaining an assembly video corresponding to the article to be assembled froma server according to the article information; the assembled video being presented to a user. As the user can assemble the articles to be assembled by watching the video, the assembling efficiency isimproved and the assembling error rate is reduced.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

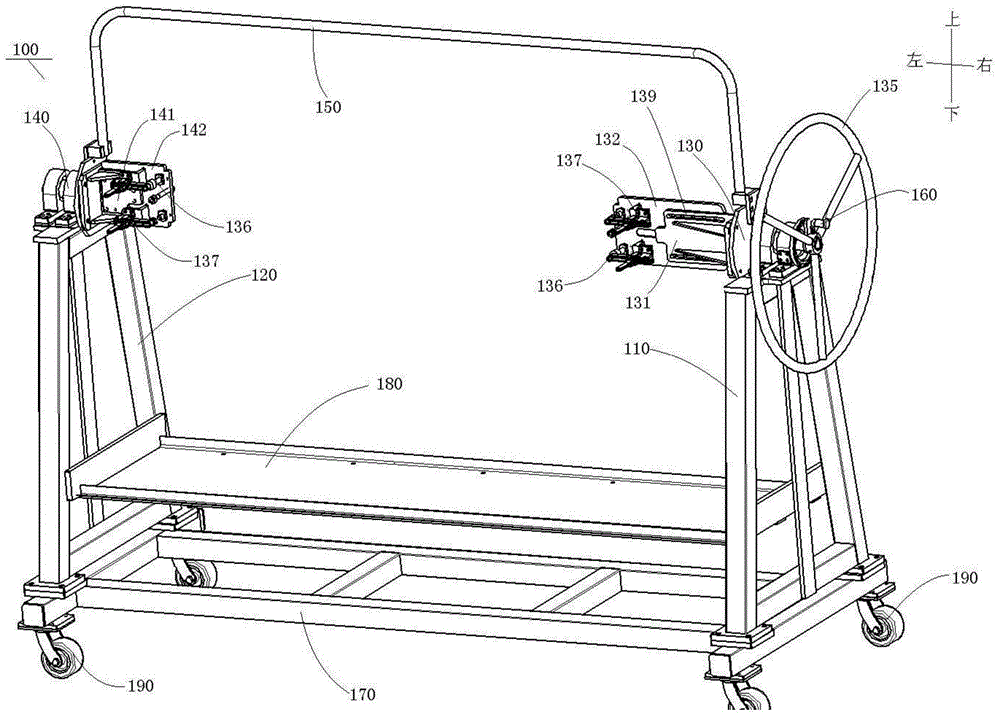

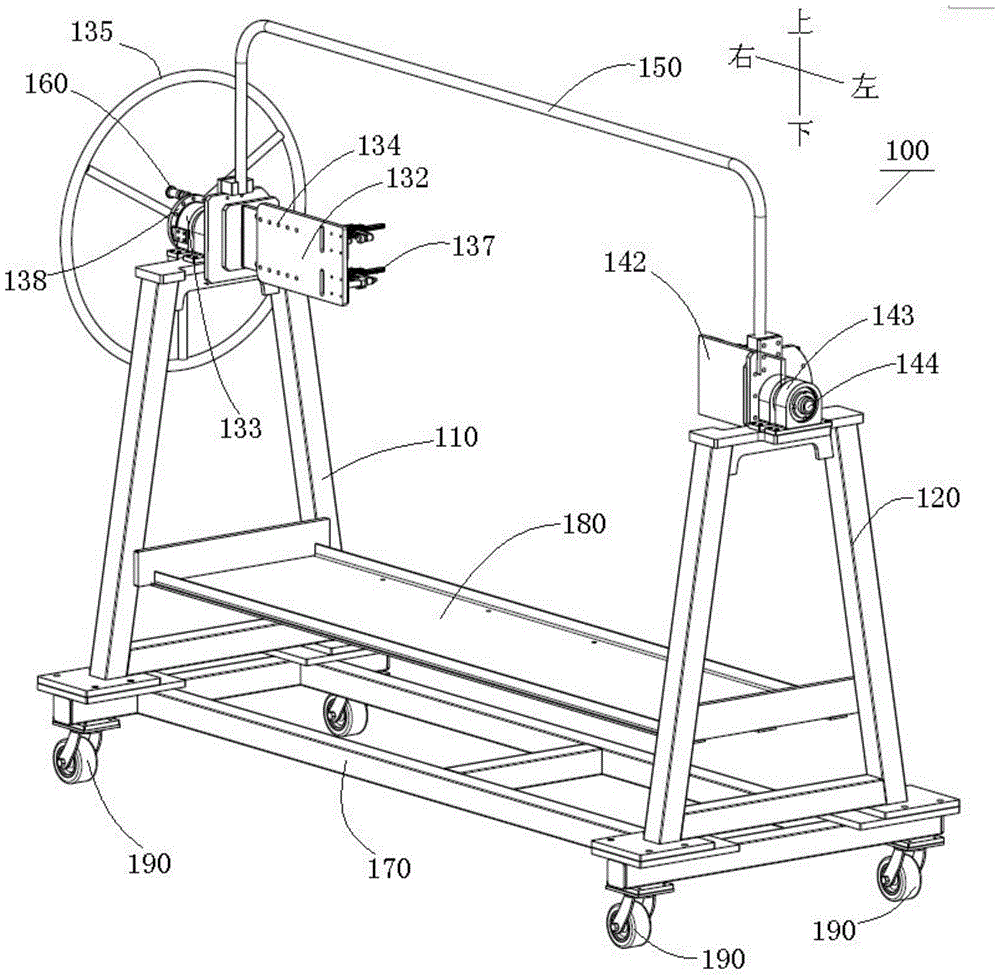

Tooling for instrument panel subassembly assembly

ActiveCN104827448BSimple structureEasy to operateAssembly machinesWork benchesEngineeringMechanical engineering

The present invention discloses a tool for assembling an instrument board sub-assembly. The tool comprises a first support frame, a second support frame, a first rotating assembly, a second rotating assembly, a synchronous stabilizer bar and a positioning part, wherein the first support frame and the second support frame are oppositely arranged; the first rotating assembly is rotatably arranged on the first support frame; the second rotating assembly is rotatably arranged on the second support frame; the synchronous stabilizer bar is connected between the first rotating assembly and the second rotating assembly; and the positioning part is arranged on one of the first rotating assembly and the second rotating assembly so as to limit a rotating angle of the corresponding rotating assembly. According to the tool for assembling the instrument board sub-assembly, disclosed by the present invention, the rotatable first rotating assembly and second rotating assembly are arranged on the first support frame and the second support frame and the positioning part is utilized to implement limitation to the rotating angle. Therefore, the instrument board sub-assembly is effectively prevented from having the defects of scratches, deformation and the like in the assembling process, so that quality of the product is improved, the assembling efficiency is improved and the production cost is reduced.

Owner:BEIQI FOTON MOTOR CO LTD

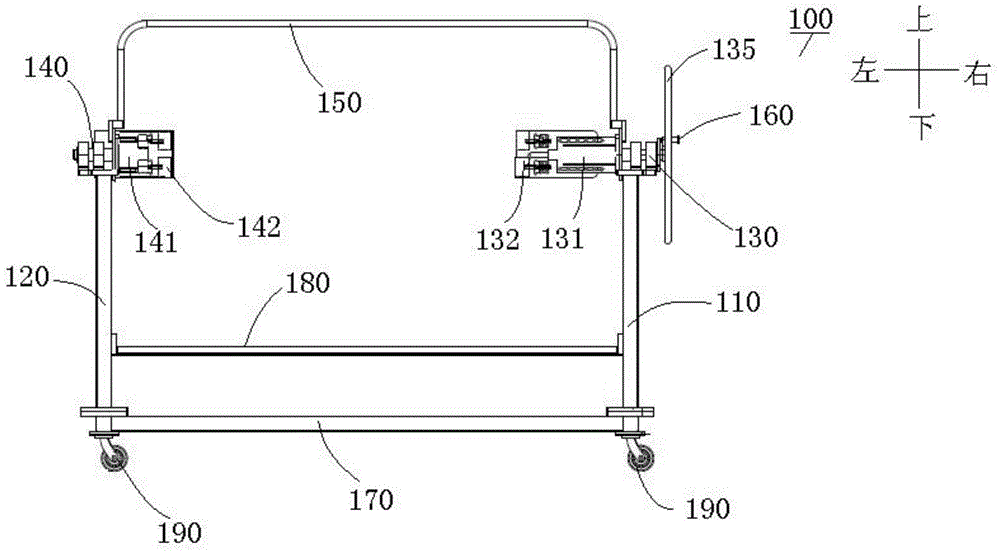

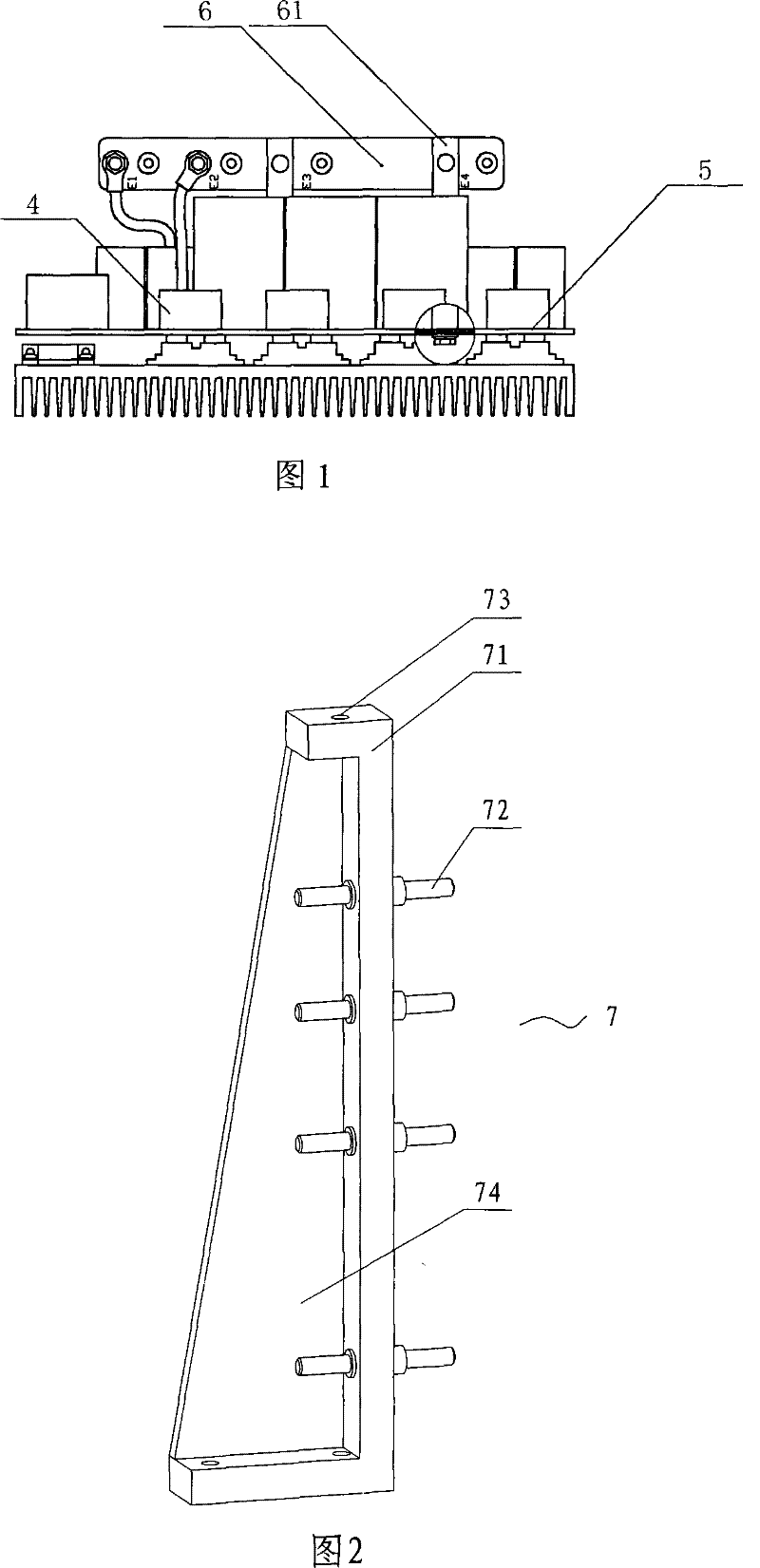

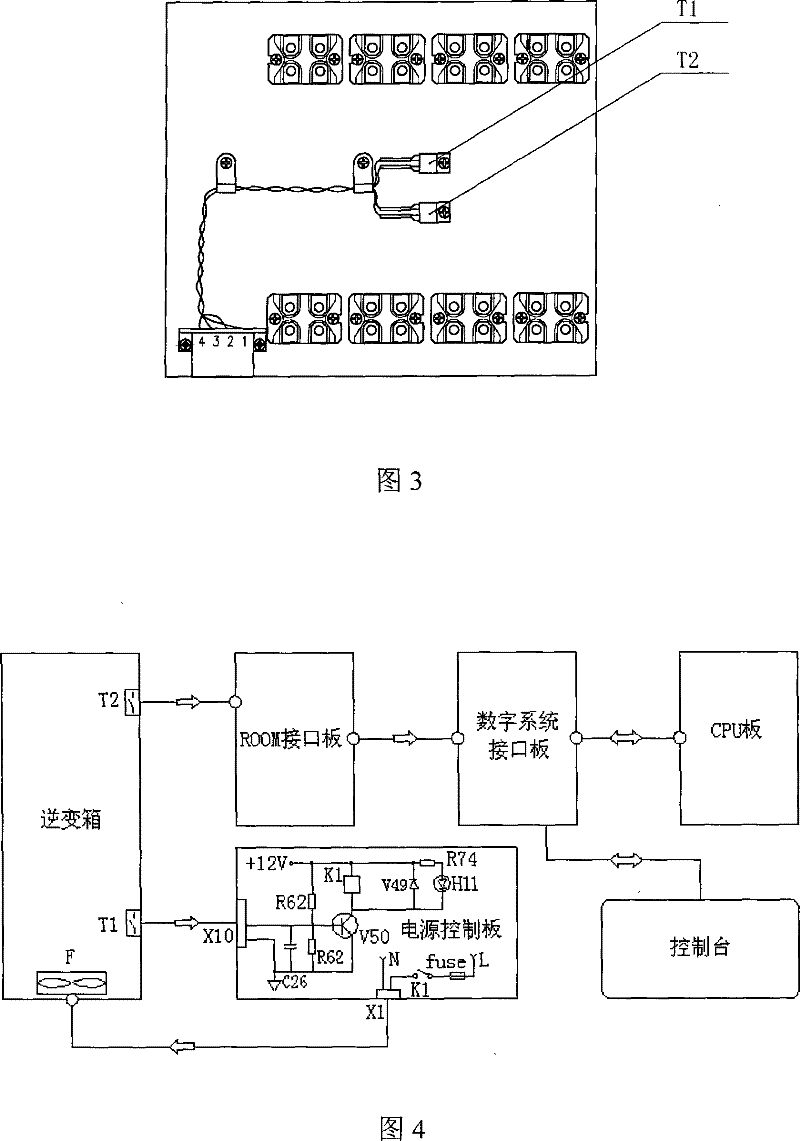

Inverter device for high-voltage generator

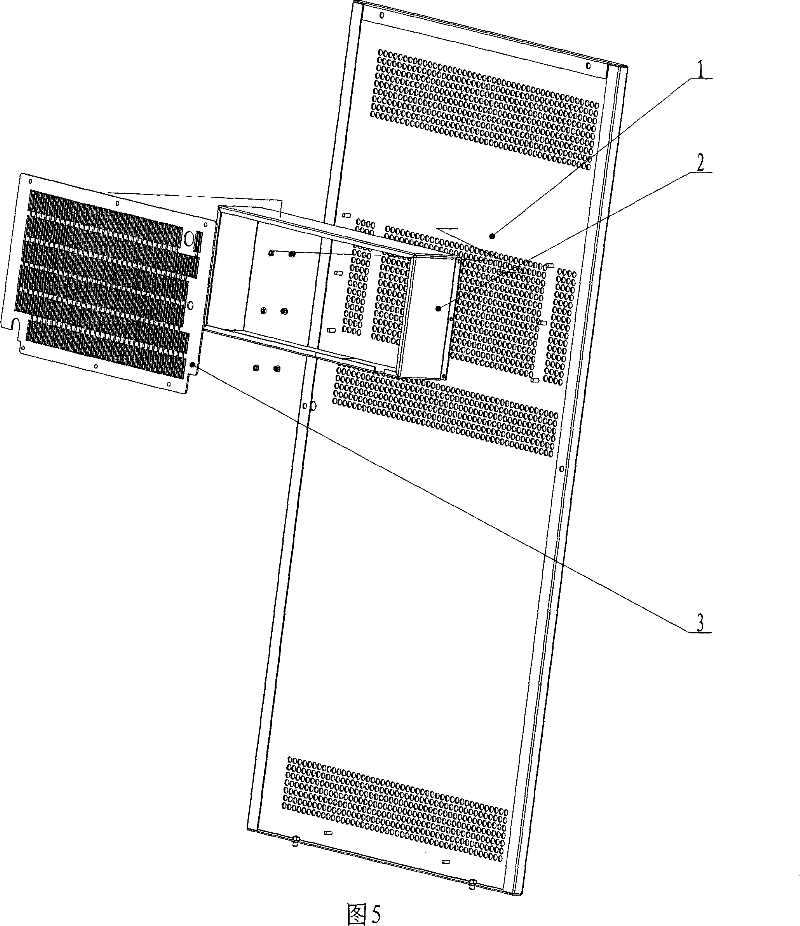

InactiveCN101460001BEasy to assembleEasy maintenanceCircuit arrangements on support structuresMetal casingsElectricityModularity

The invention relates to an inversion device of high-voltage generator, which is arranged in an inversion chamber integrally mounted in a cabinet of a high-voltage generator, and which comprises one or a plurality of inversion units. Each inversion unit is an assembled modular integral structure formed by mounting a MOS transistor, a radiating fin and an adapter panel of inversion plate on an inversion plate. Each adapter panel of inversion plate is provided with a plurality of twin electric connection holes, which is mounted on a bottom plate of the inversion chamber through an adaptor bracket. The inversion device of high-voltage generator is convenient to assemble, easy to manufacture, and effective to increase work efficiency and reduce false assembly. The cooling mode is so reasonable that a cooling fan is controlled by a temperature switch and needs no long-term operation, and the rear portion of the inversion chamber is provided with a back-up plate with air vent to correspond to an air vent and an air channel arranged on a side door of the cabinet of the high-voltage generator, thereby enlarging draught area, quickening heat dissipation of the inversion chamber, and reducing outward radio-frequency radiation caused by the inversion chamber.

Owner:NEUSOFT MEDICAL SYST CO LTD

A construction prompt method and system for a modular device

ActiveCN108115686BReduce assembly error rateEffective reminderProgramme controlProgramme-controlled manipulatorControl engineeringComputer engineering

The present invention provides a construction prompt method and system for a modular device. The construction prompt method for a modular device includes the steps of: S1: Acquire configuration information of a target modular device, and the target modular device includes M through docking parts Connected unit modules; S2: Obtain the configuration information of the currently constructed entity, the constructed entity includes N unit modules connected through docking parts, and N is less than M; S3: According to the configuration information of the target modular device and the current The configuration information of the constructed entity is calculated to obtain the docking part position where at least the (N+1)th unit module should be connected to the constructed entity; and S4: according to the calculation in step S3, at least the (N+1)th unit is obtained The module should issue a prompt message at the docking part connected to the constructed entity, prompting the docking part where at least the (N+1)th unit module should be connected. The modular device construction prompt method and system provided by the present invention can reduce the reconstruction and splicing errors of the modular device.

Owner:BEIJING KEYI TECH

Refrigerator wifi and control panel software online programming system and method

PendingCN112422664AReduce item numberHigh degree of generalizationTransmissionSoftware deploymentDisplay boardIcebox

The invention discloses a refrigerator wifi and control panel software online programming system and method, and relates to the technical field of refrigerator production and assembly. The system comprises a refrigerator display panel, a refrigerator wifi panel and a programming subsystem, wherein the refrigerator wifi panel uniformly programs one piece of solidified software when leaving a factory; the solidification software is used for being in communication connection with the programming subsystem and receiving wifi software sent by the programming subsystem according to the refrigeratormodel to perform system ISP programming; the refrigerator wifi module receives the display panel software sent by the programming subsystem and carries out system programming on the display panel; therefrigerator display panel is used for receiving the display panel software transmitted by the wifi panel; the programming subsystem is composed of a bar code scanning module, a wireless communication module, a file management module and a result broadcasting module. After the display panel and the wifi panel with the same hardware and different software are respectively unified into one materialaccording to the hardware state, the material cost and the assembly error rate of the refrigerator control panel are favorably reduced.

Owner:合肥美菱物联科技有限公司

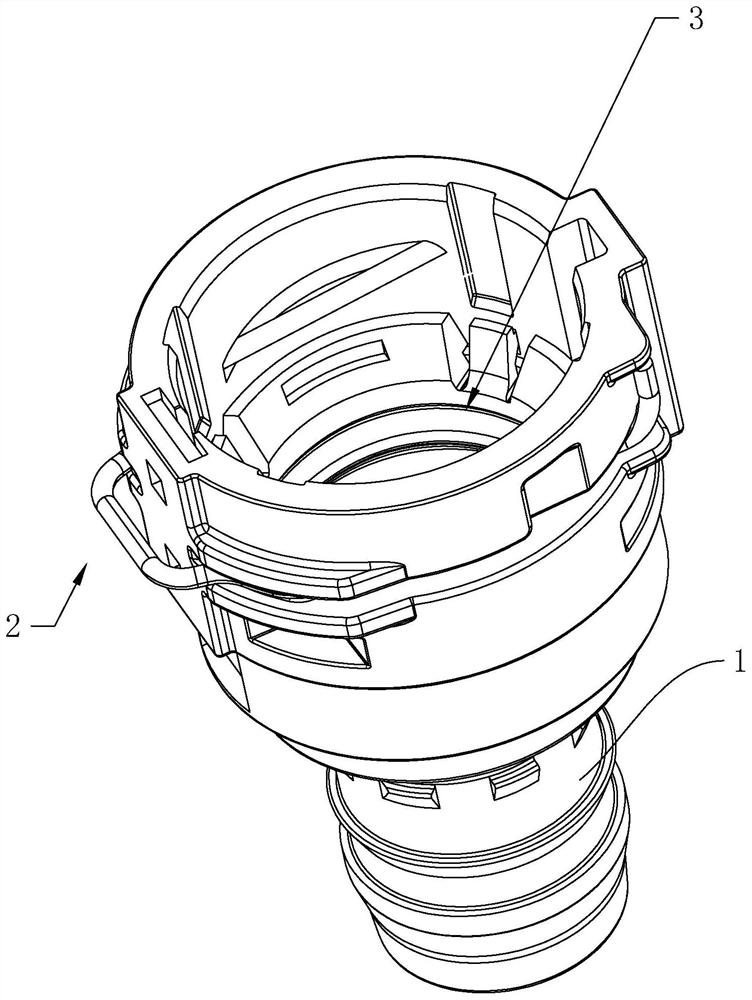

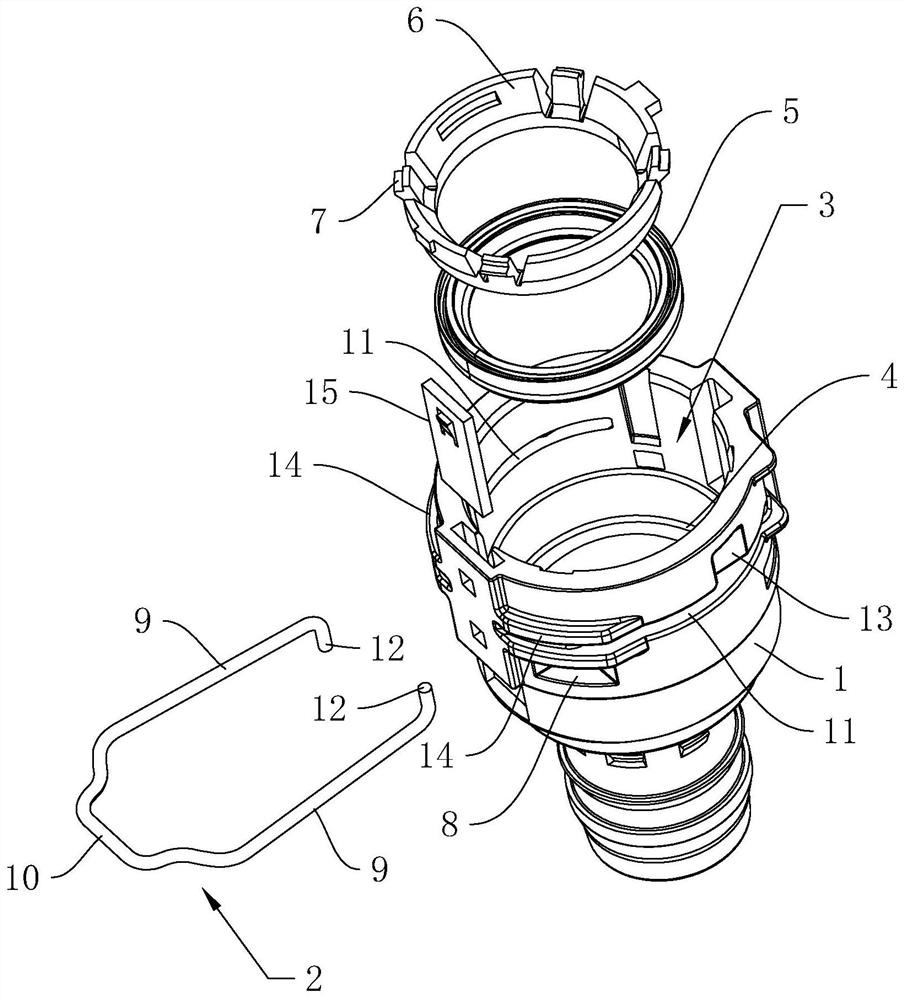

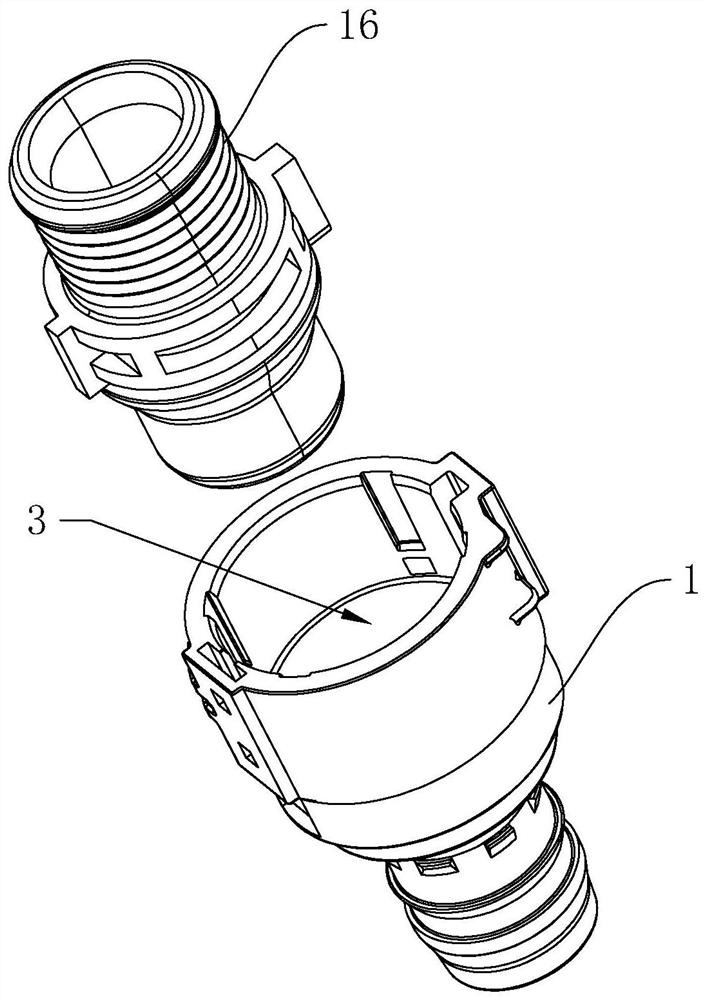

Rapid connector used for automobile cooling water pipe

InactiveCN111928028AEasy to insertImprove connection reliabilitySleeve/socket jointsEngineeringMechanical engineering

The invention relates to a rapid connector used for automobile cooling water pipe. The rapid connector comprises a hollow connector body. The two ends of the connector body communicate. The connectorbody comprises a connector used for being connected with a cooling water guide pipe. An elastic piece is arranged in the connector body in the manner that the elastic piece is coaxial with the connector. The rapid connector has the characteristic that the cooling water guide pipe is convenient to assemble.

Owner:ZHEJIANG JUNHE RUBBER TECH

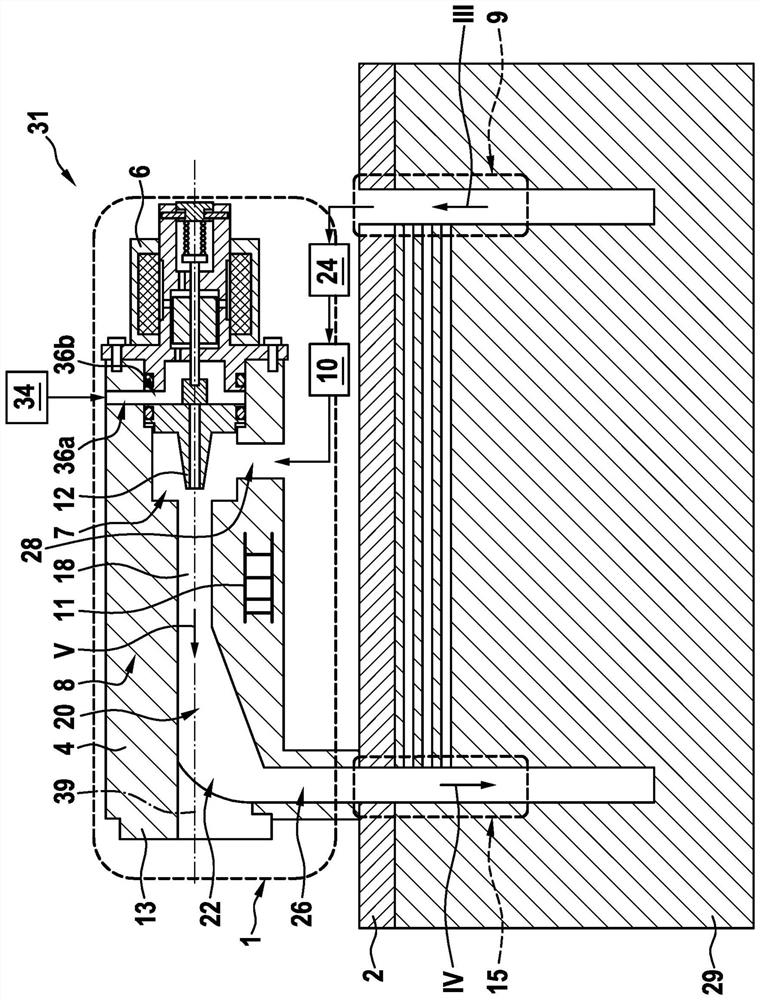

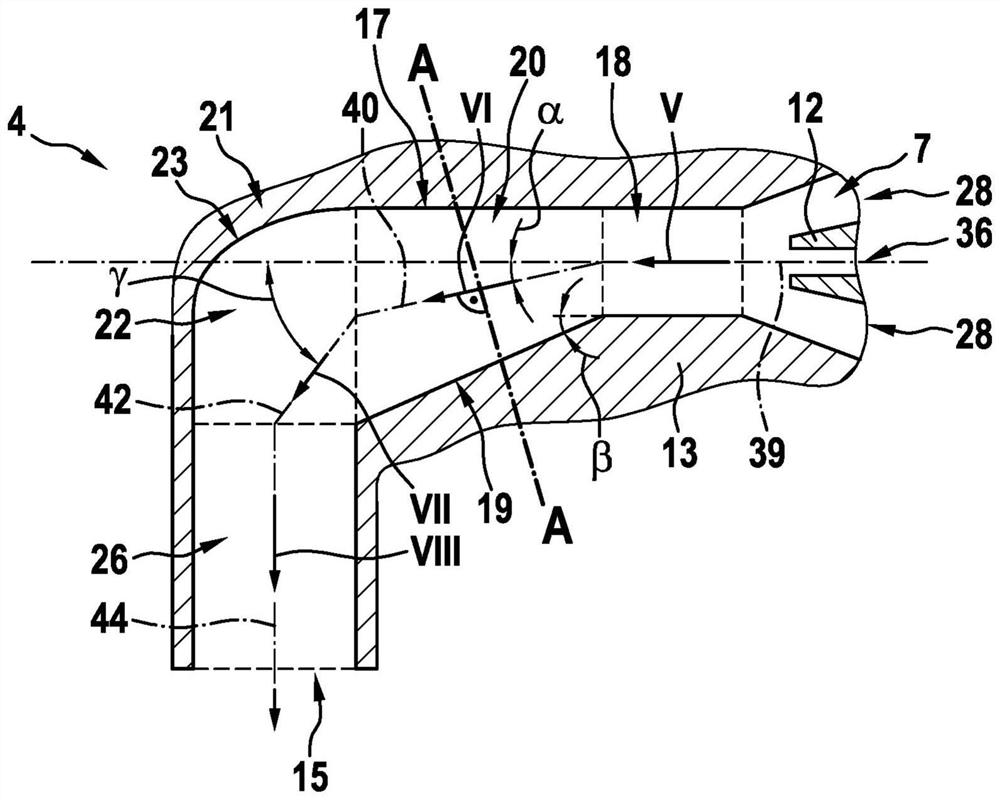

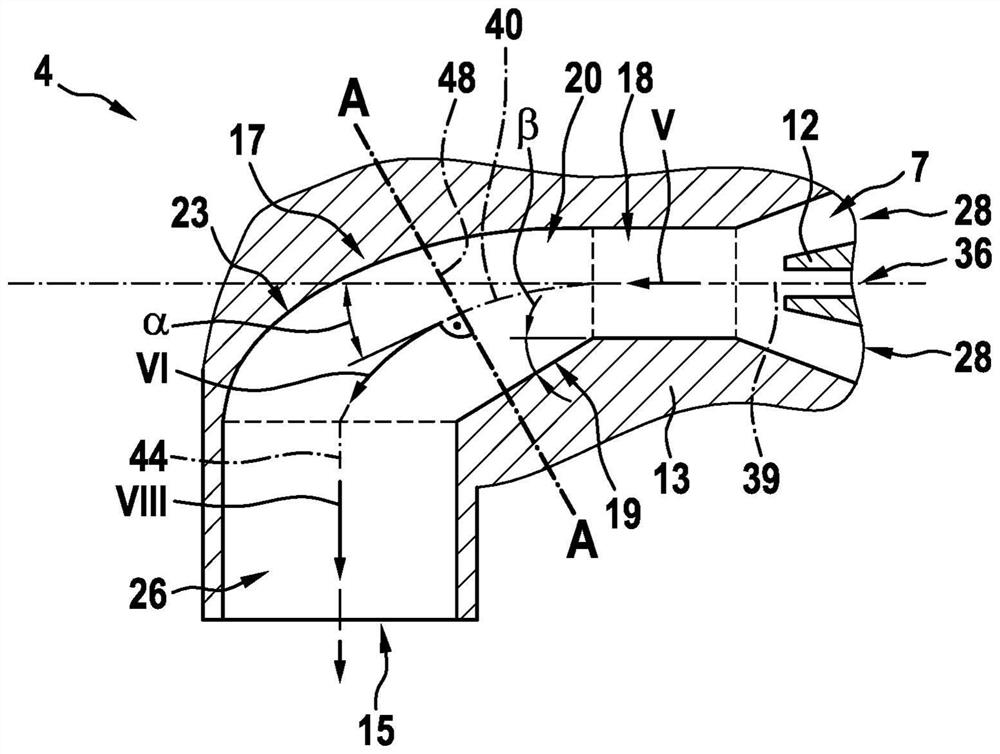

Conveyor unit for a fuel cell system for conveying and/or controlling a gaseous medium

PendingCN113646544AImprove jet pump performanceReduce deflectionJet pumpsMachines/enginesFuel cellsInjection pump

The invention relates to a conveyor unit (1) for a fuel cell system (31) for conveying and / or controlling a gaseous medium, in particular hydrogen, comprising a jet pump (4), which is driven by a propulsion jet of a pressurized gaseous medium, and a metering valve (6), an outlet of the conveyor unit (1) being fluidically connected to an anode inlet (15) of a fuel cell (29). The jet pump (4) has a suction region (7), a mixing tube (18), and a diffuser (20), wherein the diffuser (20) is at least indirectly fluidically connected to the anode inlet (15) of the fuel cell (29), and the gaseous medium flows through the jet pump (4) at least partly in the direction of a first flow direction (V) which runs parallel to a first longitudinal axis (39) of the mixing tube (18). According to the invention, a second longitudinal axis (40) of the diffuser (20) is curved or inclined relative to the first longitudinal axis (39) of the mixing tube (18).

Owner:ROBERT BOSCH GMBH

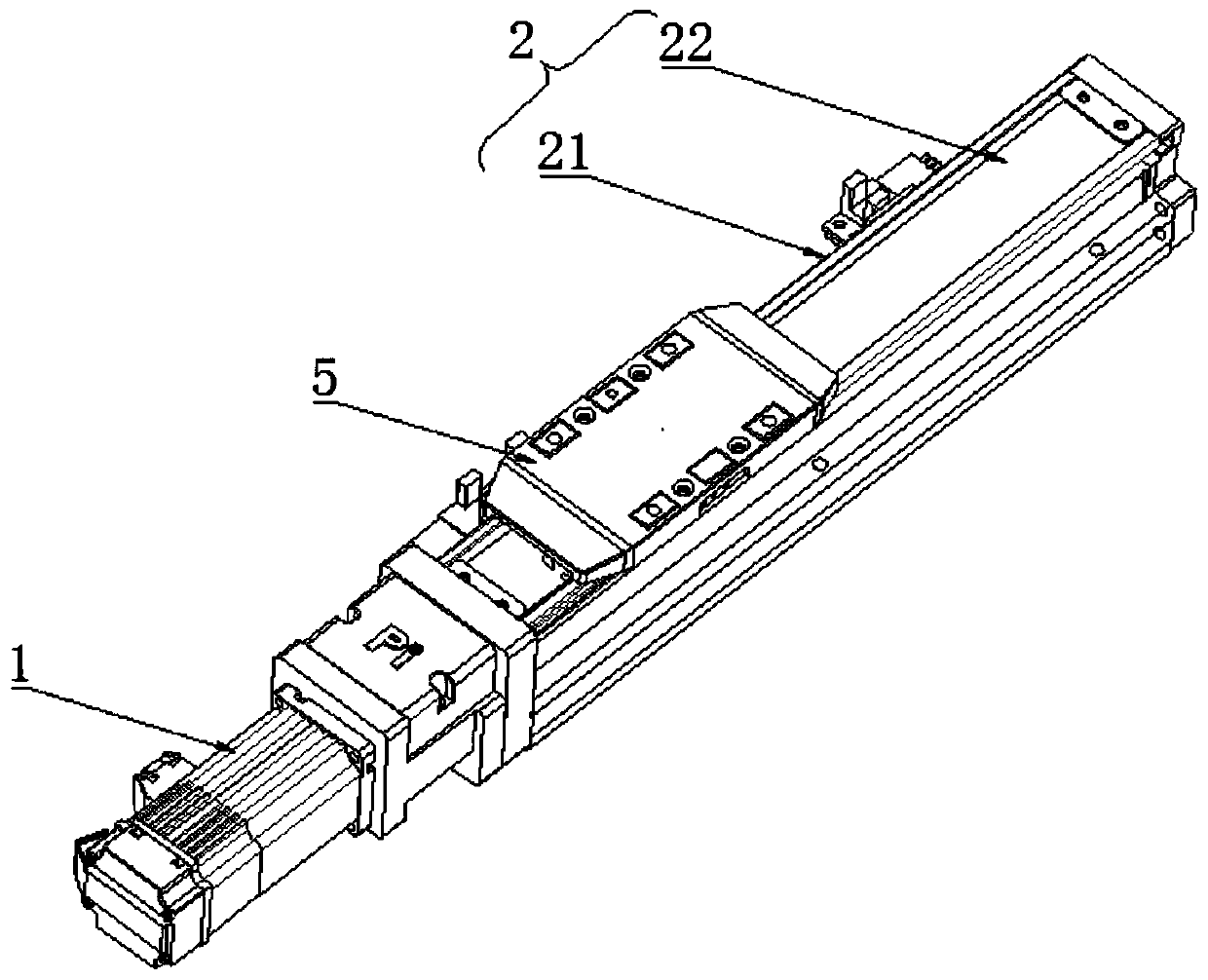

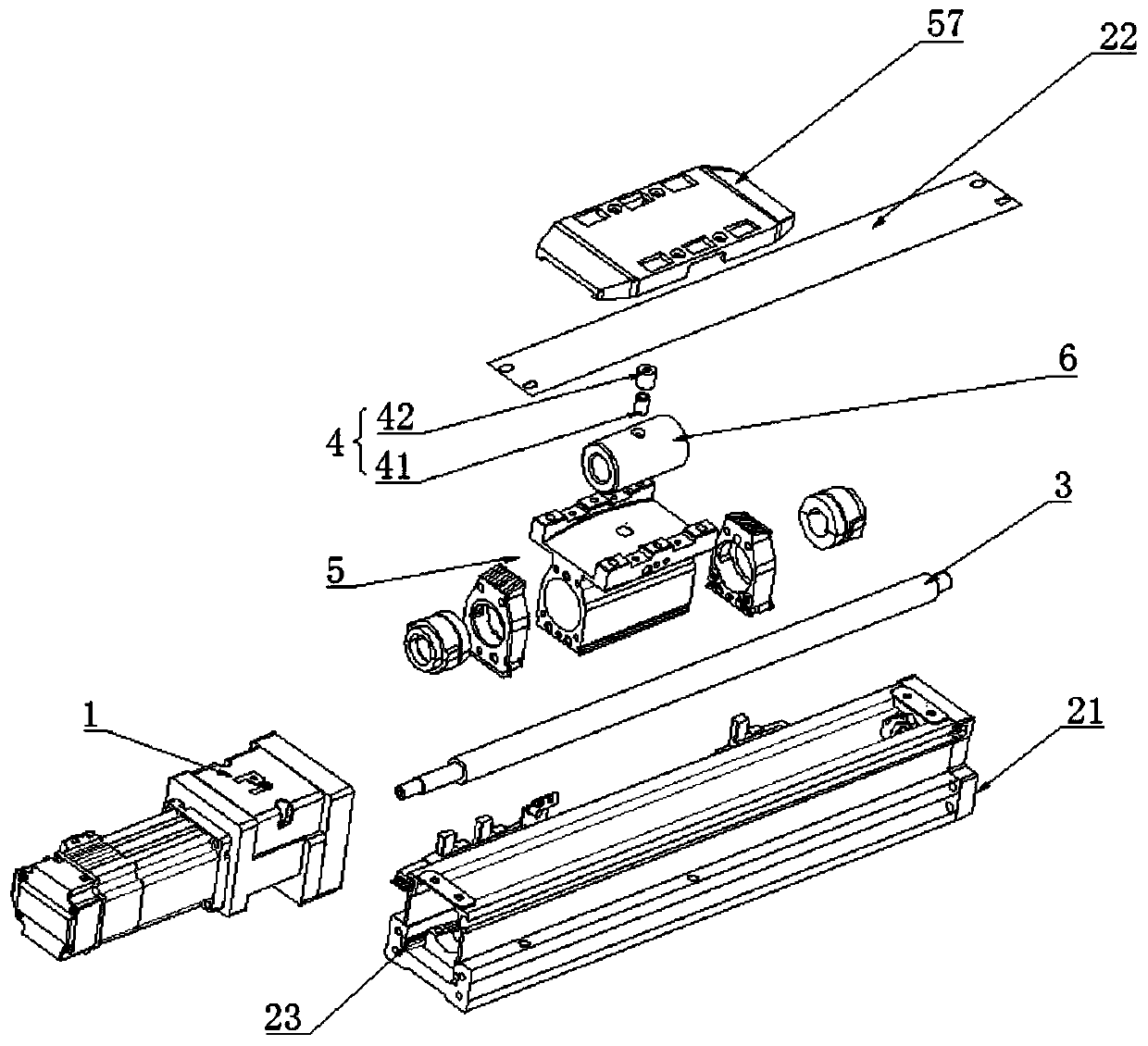

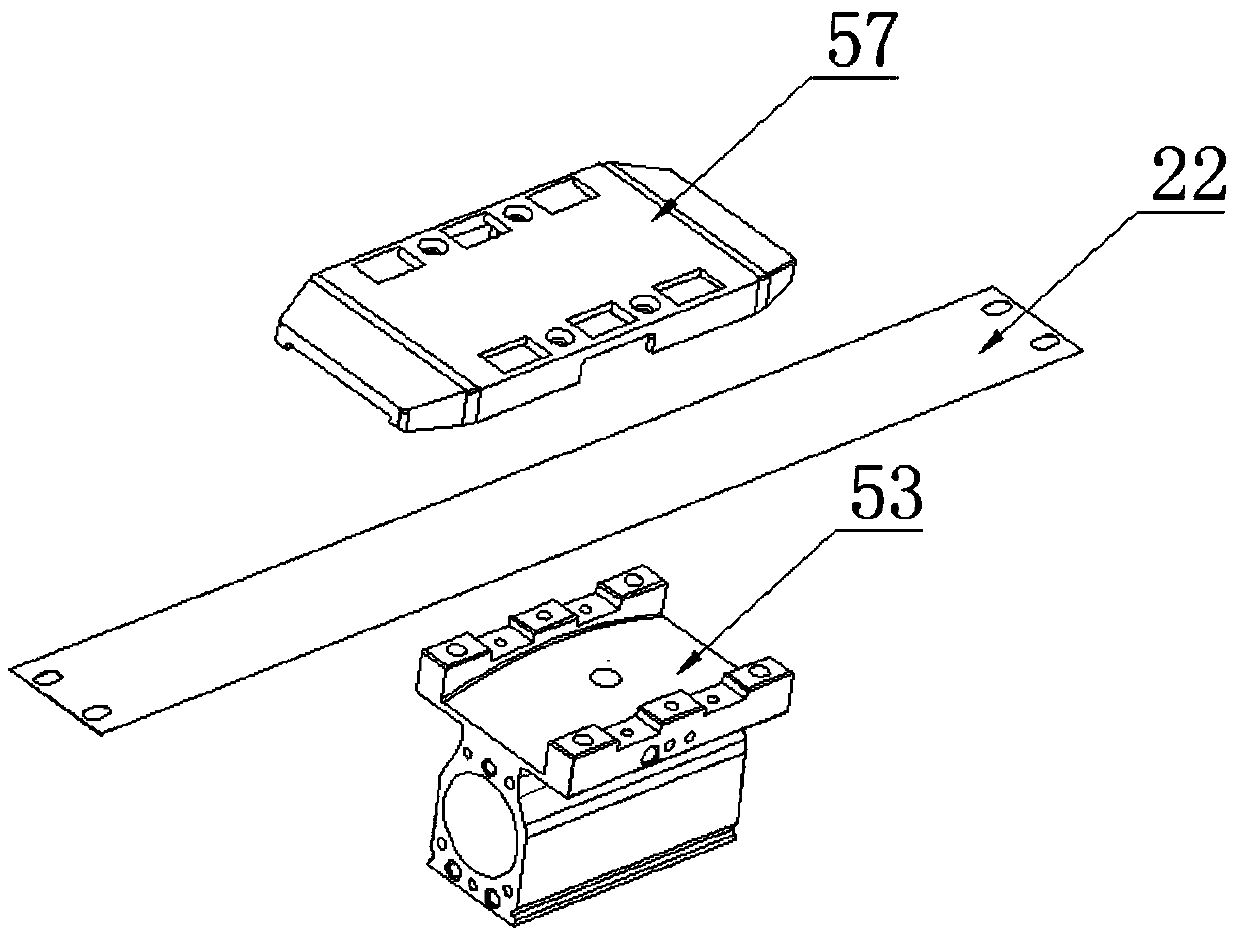

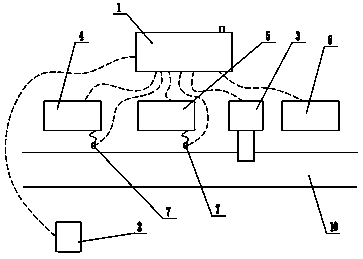

Novel ball screw rod device

PendingCN109707814ASimple structureEasy to assembleGearingGear lubrication/coolingBall screwEngineering

The invention discloses a novel ball screw rod device. The novel ball screw rod device comprises a motor, a screw rod, a nut, a sliding seat and a plug pin assembly; a mounting hole is formed in the middle of the sliding seat, and the nut is coaxially embedded into the mounting hole; the screw rod penetrates through the mounting hole and is in screw connection with the nut; a first through hole isformed in the top of the sliding seat, and a plug pin hole is formed in the position, corresponding to the first through hole, of the periphery side of the nut; the plug pin assembly is used for fixedly connecting the nut and the sliding seat through the first through hole and the plug pin hole; the sliding seat is further provided with a plurality of oil storage tanks and a plurality of flow channels, and the flow channels are used for communicating with the oil storage tanks to pump in lubricating oil; and the motor is used for driving the screw rod to drive the sliding seat to slide through the nut. The novel ball screw rod device is convenient to assemble and convenient to lubricate, has a compact structure, saves cost and has high practicability.

Owner:深圳市锐健电子有限公司

Automatic selecting and assembling device and selecting and assembling method for main bearing bushings, connecting rod bushings and cylinder cover gaskets

PendingCN109702448AImprove assembly qualitySave assembly timeMeasurement devicesAssembly machinesElectricityMeasuring instrument

The invention discloses an automatic selecting and assembling device for main bearing bushings, connecting rod bushings and cylinder cover gaskets. The automatic selecting and assembling device comprises a selecting and assembling controller, a main bearing hole measurer and a piston protrusion quantity measuring instrument, and further comprises a main bearing bushing output device, a connectingrod bushing output device and a cylinder cover gasket output device which are sequentially arranged and electrically connected with the selecting and assembling controller separately; the main bearingbushing output device and the connecting rod bushing output device are each provided with a barcode scanner, and the barcode scanners are electrically connected with the selecting and assembling controller; the main bearing bushing output device is provided with multiple main bearing bushing output boxes, the connecting rod bushing output device is provided with multiple connecting rod bushing output boxes, and the cylinder cover gasket output device comprises multiple cylinder cover gasket output boxes; and the piston protrusion quantity measuring instrument is electrically connected with the cylinder cover gasket output device and the selecting and assembling controller. According to the automatic selecting and assembling device for the main bearing bushings, the connecting rod bushingsand the cylinder cover gaskets, the assembling time is greatly shortened, the assembling error rate is decreased, and the assembling quality of a diesel engine and the consistency and reliability ofa product batch are improved.

Owner:WEICHAI POWER YANGZHOU DIESEL ENGINE

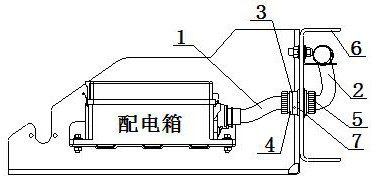

Wire harness structure of vehicle distribution box

PendingCN113871959AEasy to produceRealize separate installationIncorrect coupling preventionTwo-part coupling devicesMechanical engineeringCable harness

The invention discloses a vehicle distribution box wire harness structure. A distribution box wire harness comprises a distribution box end wire harness and an electric appliance end wire harness, and the distribution box end wire harness is connected with the electric appliance end wire harness through a connector; one end of the distribution box end wire harness is connected with the distribution box, the other end of the distribution box end wire harness is connected with one end of the connector, the other end of the connector is connected with the electrical appliance end wire harness, and the other end of the electrical appliance end wire harness is connected with a wiring end of each electrical appliance. According to the design, the design cost can be reduced, the assembly efficiency is improved, and the modularization degree of equipment is improved.

Owner:DONGFENG AUTOMOBILE COMPANY

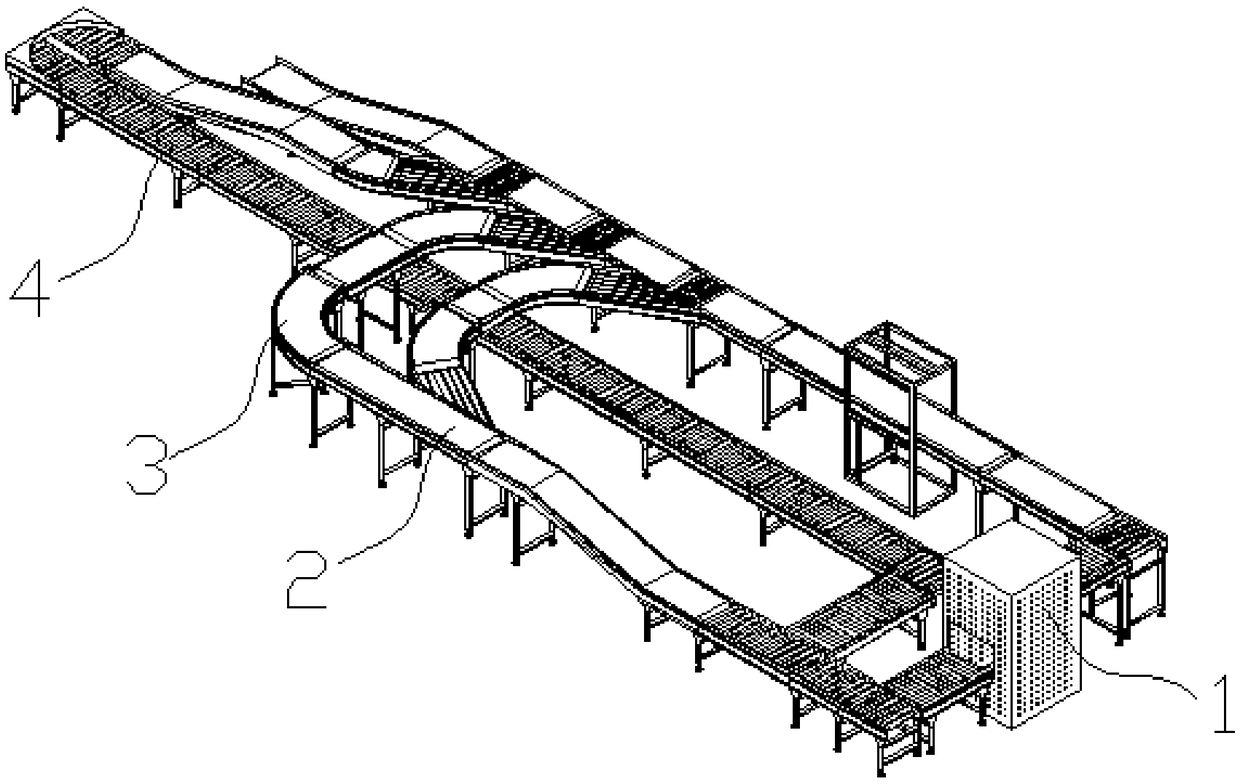

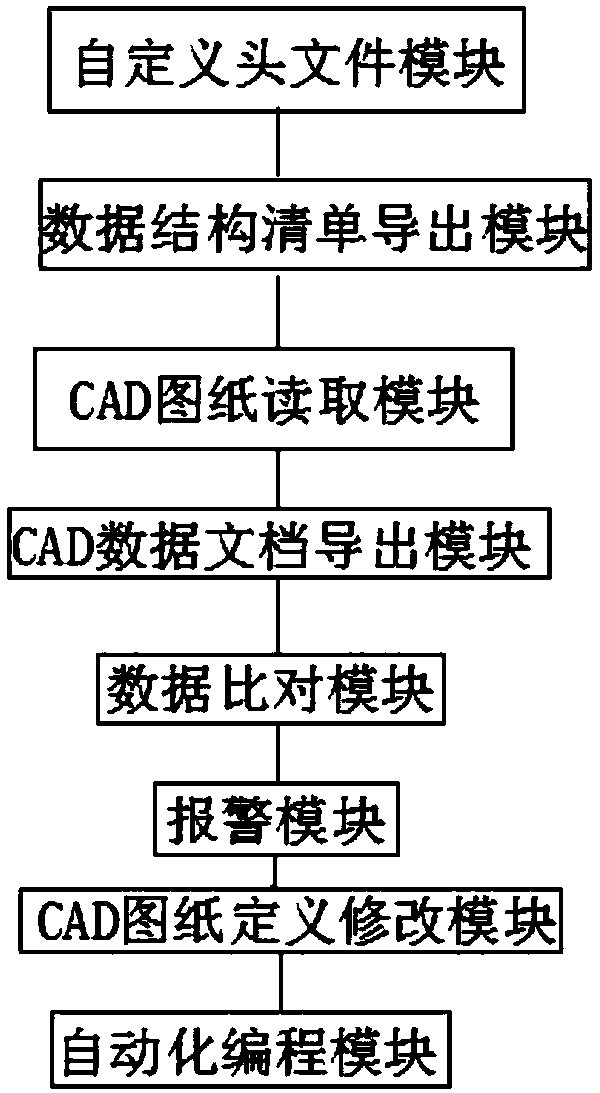

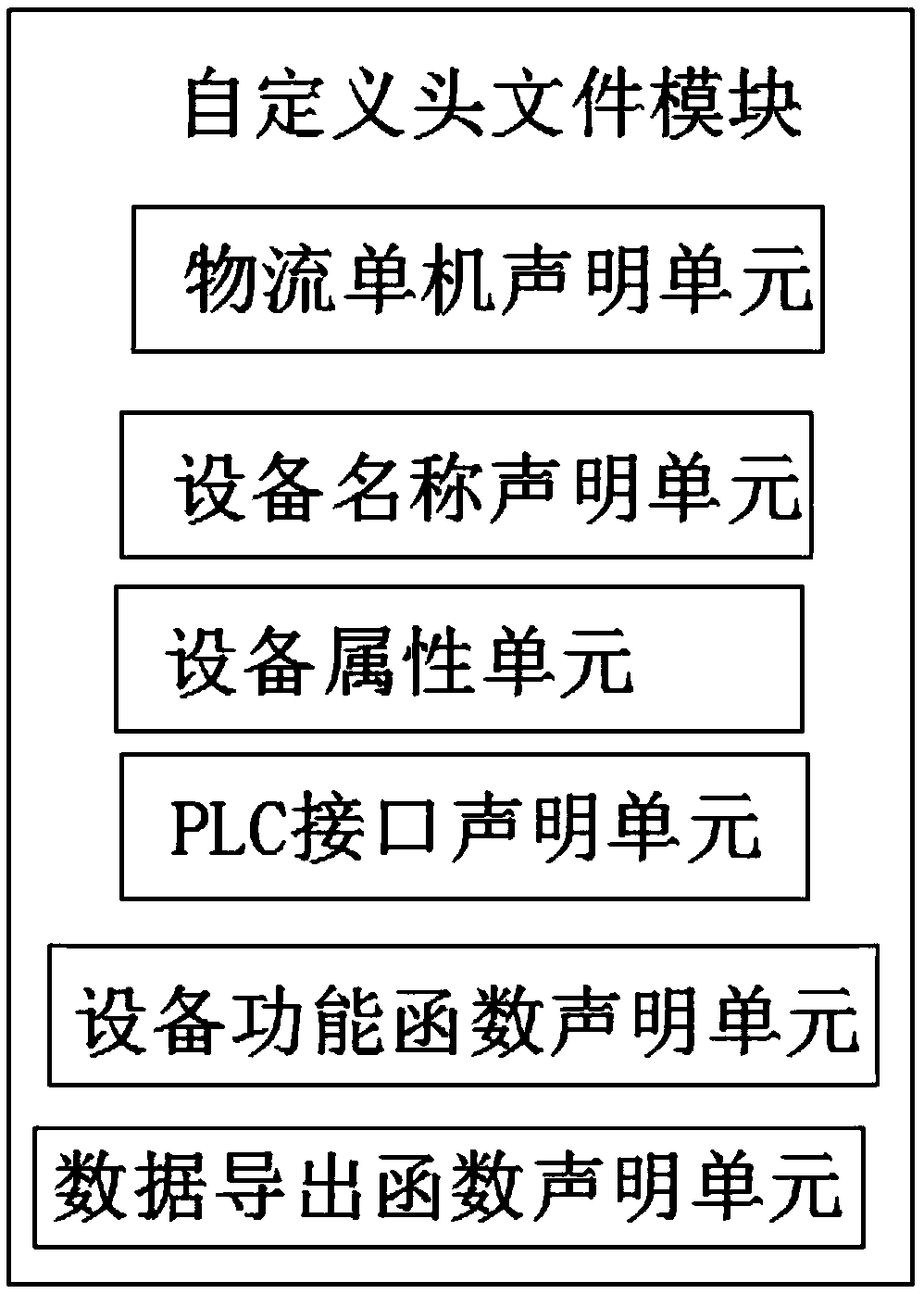

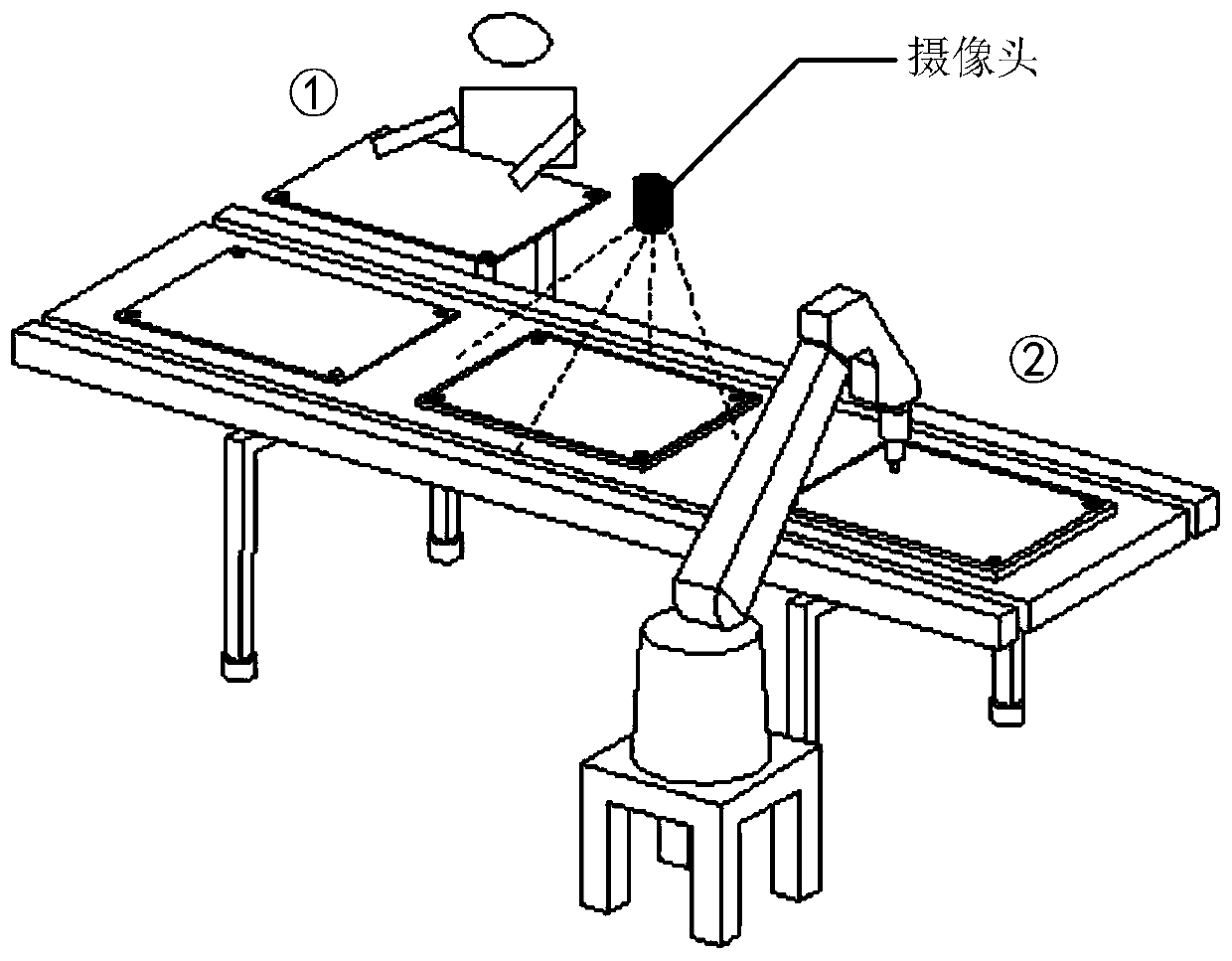

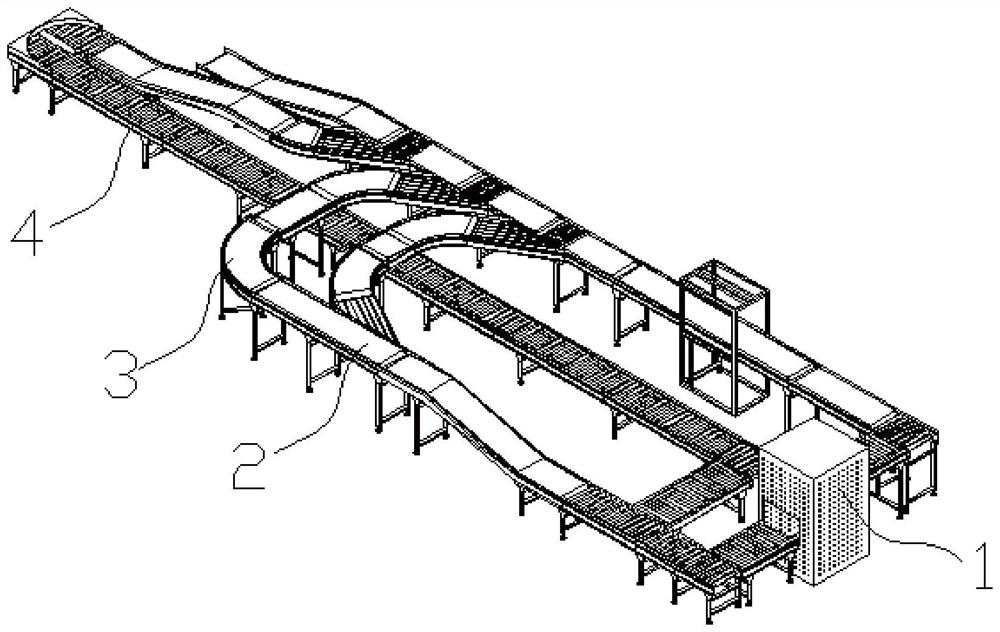

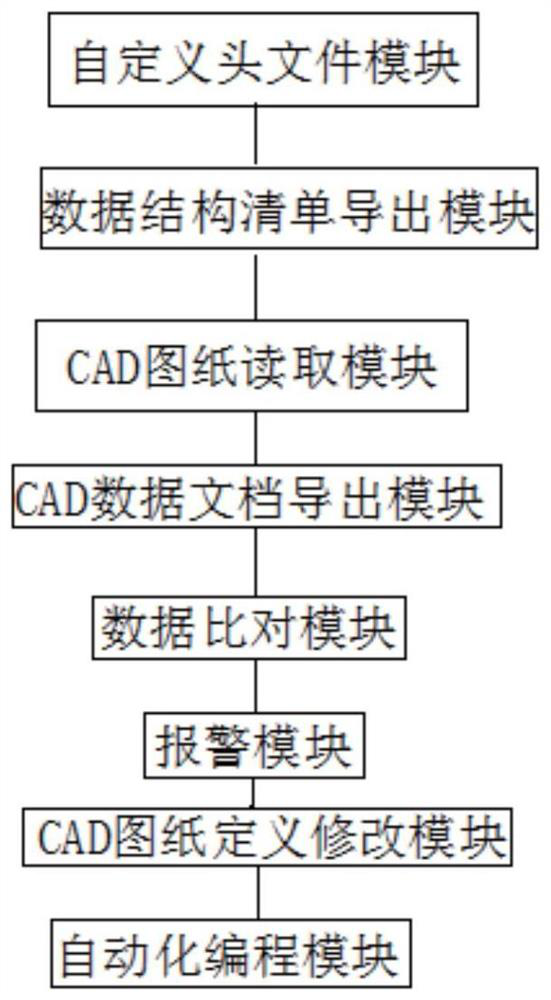

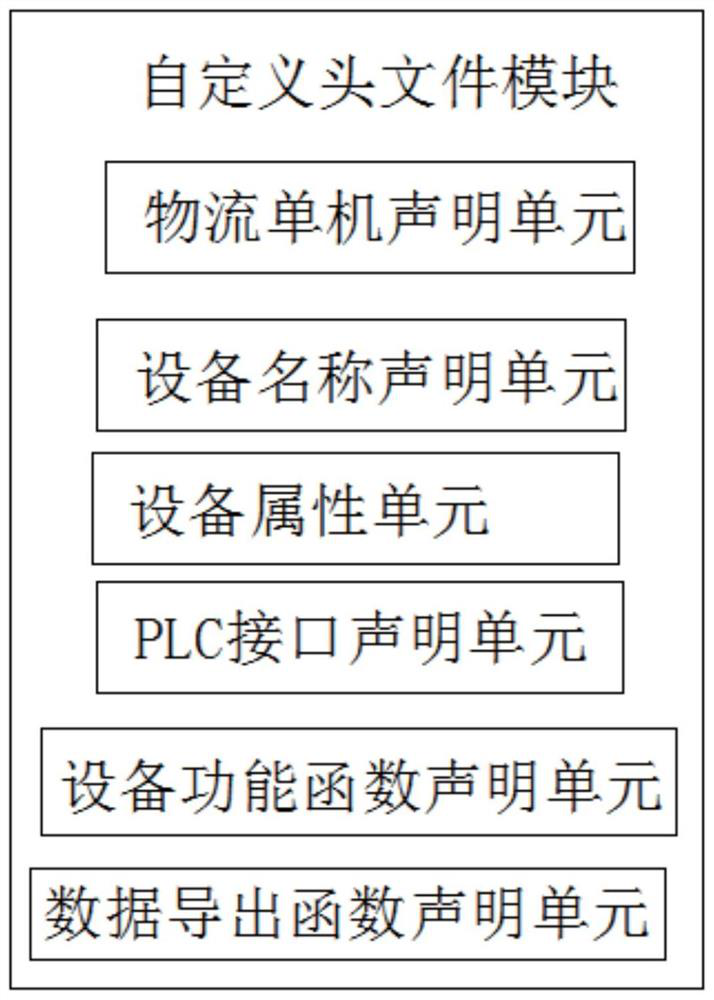

Intelligent conveying software and hardware integrated assembling system and technology

ActiveCN109143957AIntegrated intelligenceImprove reliabilityProgramme control in sequence/logic controllersLogistics managementComputer module

The invention provides an intelligent conveying software and hardware integrated assembling system and technology. The system comprises a customized header file module, a data structure list export module, a CAD drawing reading module, a CAD data file export module, a data comparison module, a CAD drawing defining and modifying module and an automatic programming module; and correspondingly, the technology comprises the steps of exporting a data structure list from a customized header file, reading a CAD drawing, exporting a CAD data file, comprising the data structure list with the CAD data file, calling the customized header file according to a comparison result and implementing automatic programming. According to the system and technology, hardware assembling and software integration ofa logistic machine can be realized intelligently automatically, the fault rate of hardware assembling is reduced, and especially in intelligent workshop development application, the system and technology can reduce development time greatly, the software and hardware integrates assembling efficiency is improved, and intelligent conveying and dispersing of logistics in the workshop are also realized.

Owner:KUNSHAN TUNGRAY IND AUTOMATION

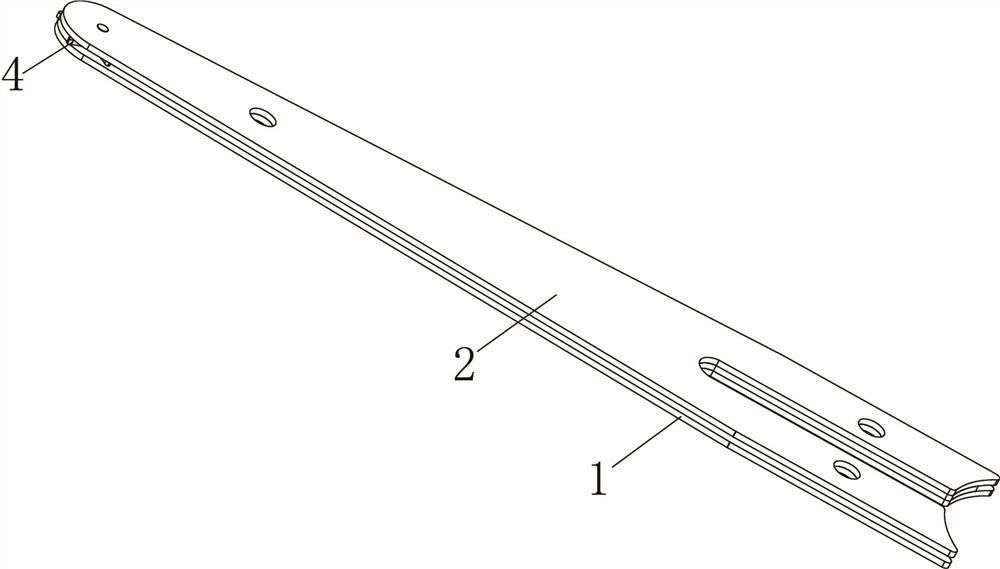

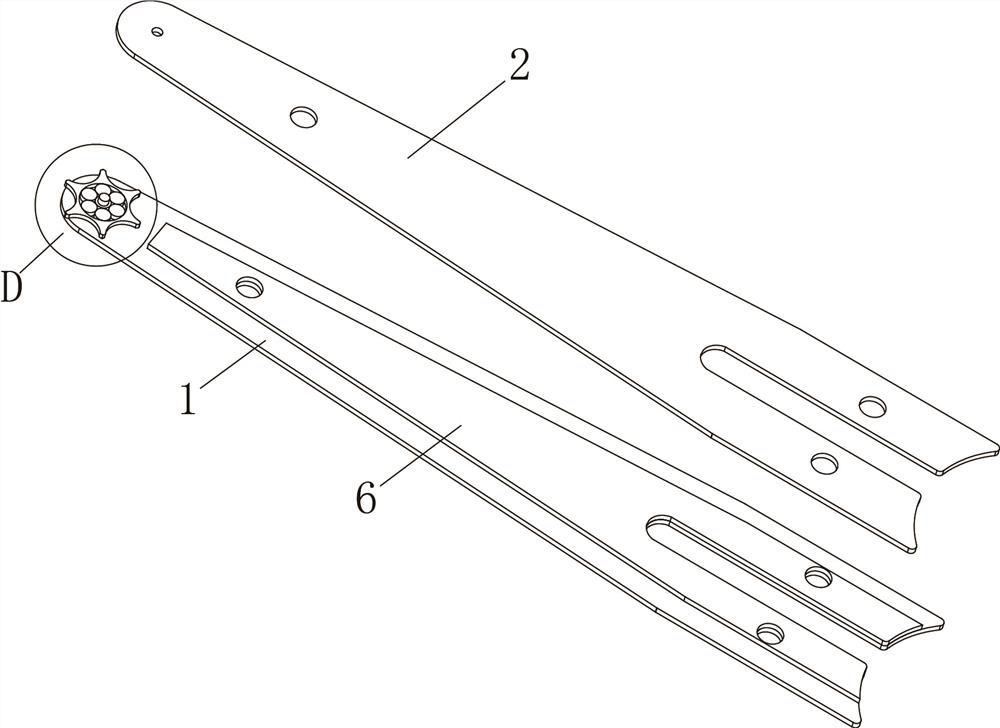

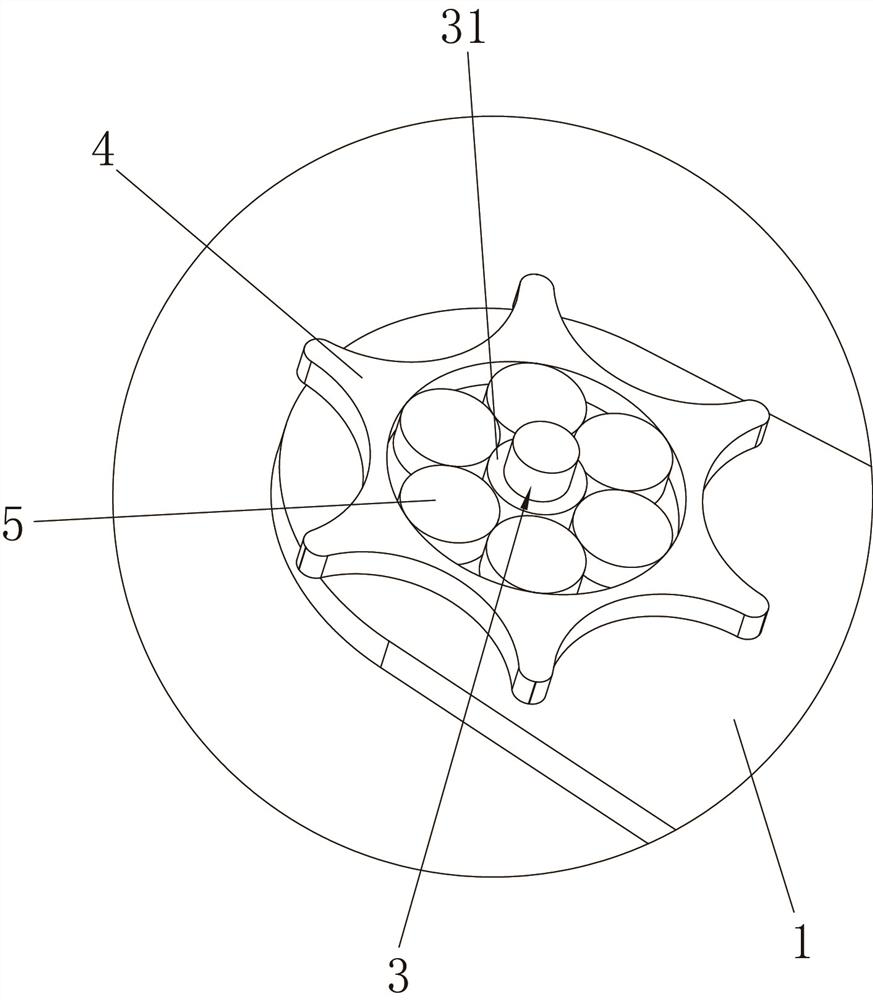

Chain saw guide plate structure

PendingCN113305942AAvoid damageReduced assembly stepsChain sawsWorking accessoriesBoard structureIndustrial engineering

The invention discloses a chain saw guide plate structure. The chain saw guide plate structure comprises a first guide plate, a second guide plate and a guide wheel, wherein the guide wheel is arranged between the first guide plate and the second guide plate and comprises a matching hole; a connecting shaft and a rolling piece are arranged in the matching hole; the two ends of the connecting shaft are connected with the first guide plate and the second guide plate respectively, the connecting shaft comprises an integrally-formed rolling bearing part, the rolling bearing part is matched with the rolling piece and positions the guide wheel, and the guide wheel can rotate along the outer wall of the rolling piece. An existing rivet and a centering ferrule are integrated into one part, namely the connecting shaft, the step of assembling the rivet and the centering ferrule is omitted, and the assembling time can be shortened; the size of the connecting shaft can be changed, the diameter of the rolling bearing part on the integrally-formed connecting shaft can be reduced, and correspondingly, the diameter of the rolling piece can be increased, so that assembly is facilitated; and after the diameter of the rolling piece is increased, the numerical values of the diameter and the thickness of the rolling piece are changed, whether the rolling piece is horizontally arranged or vertically arranged can be obviously distinguished, and the assembly error rate is reduced.

Owner:胡得一

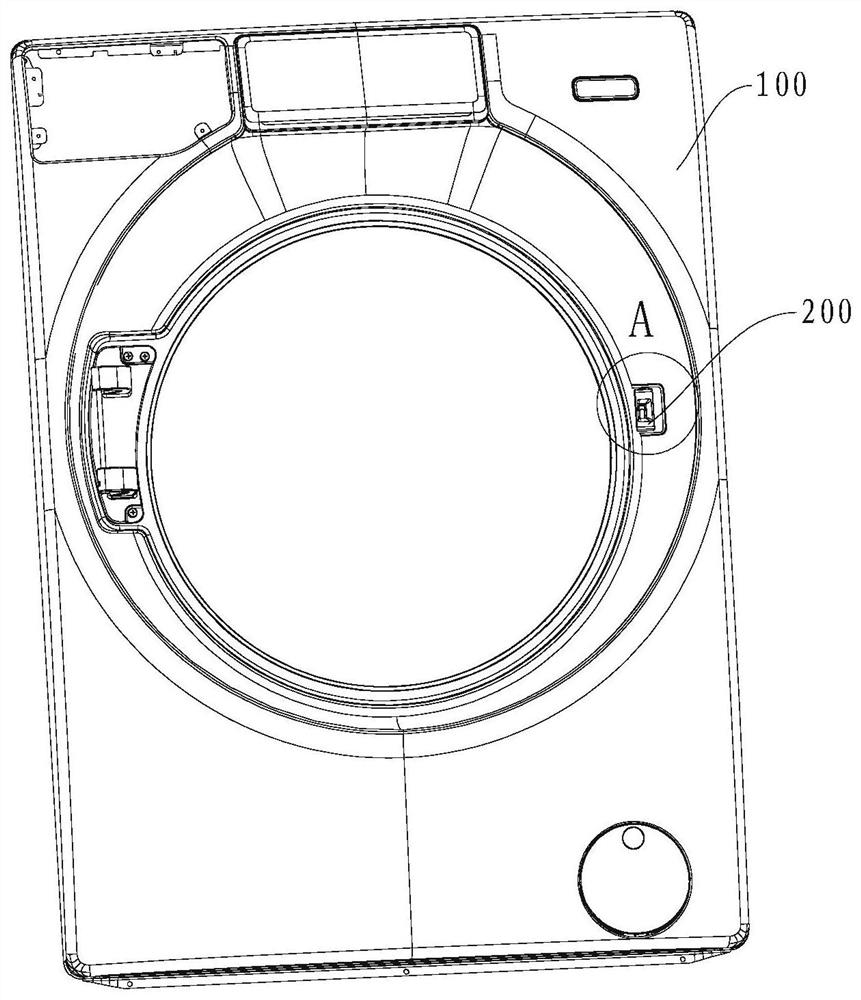

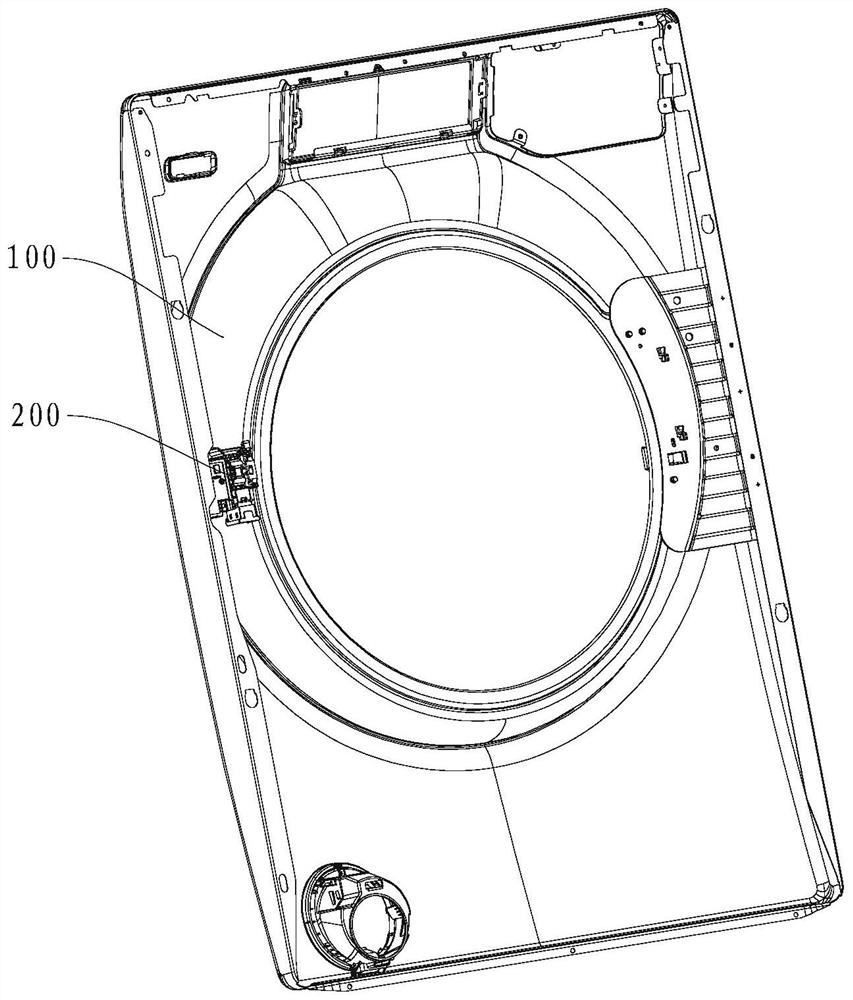

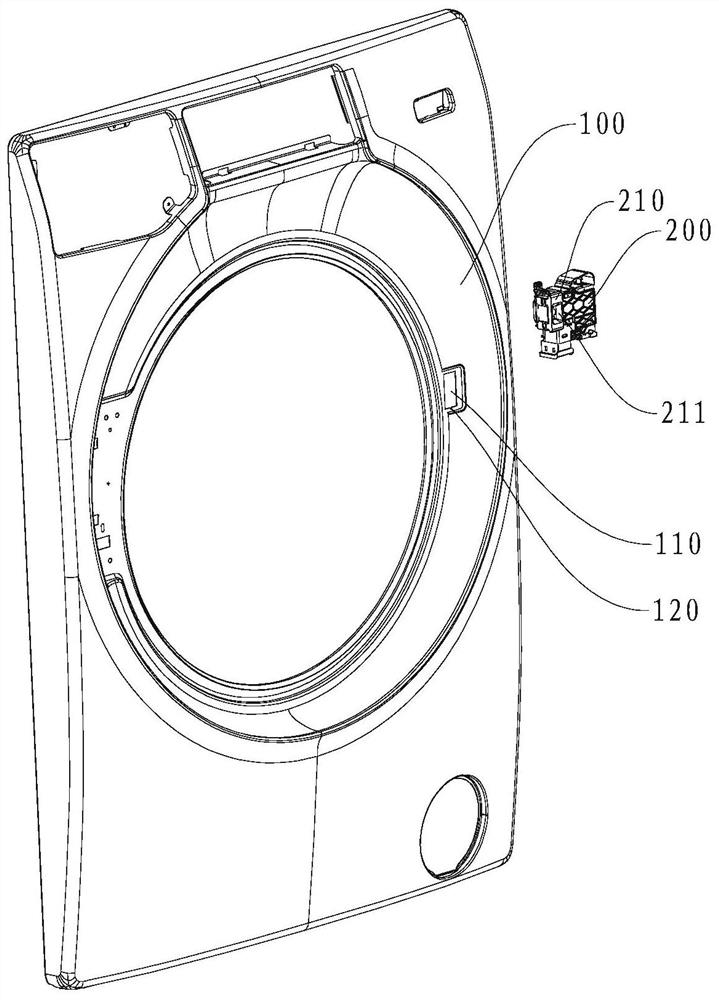

Fool-proof mounting structure for door lock and washing machine

PendingCN111691133ASimple structureImprove assembly efficiencyOther washing machinesLock casingsLaundry washing machineStructural engineering

The invention discloses a fool-proof mounting structure for a door lock and a washing machine. The door lock is mounted on a front plate, the front plate is provided with a door lock mounting hole, the door lock comprises an insertion hole portion, the insertion hole portion is provided with an insertion hole, the insertion hole corresponds to the door lock mounting hole, and the lower side of thedoor lock mounting hole is provided with a fool-proof portion. The upper and lower ends of the outer side of the insertion hole portion abut against the outer side surface of the front plate at the door lock mounting hole and are clamped into the door lock mounting hole. When the insertion hole portion is mounted in place through the inner side of the front plate, the lower end of the outer sideof the insertion hole portion covers the fool-proof portion. The fool-proof mounting structure for the door lock is simple in structure. By arranging the fool-proof portion on the lower side of the front plate mounting hole, when the door lock is mounted in place, the fool-proof portion cannot be observed, whether or not the door lock is mounted in place can be visually and quickly judged, a worker can perform self-inspection, the assembly efficiency is improved, the assembly error rate is lowered, and the product quality is improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

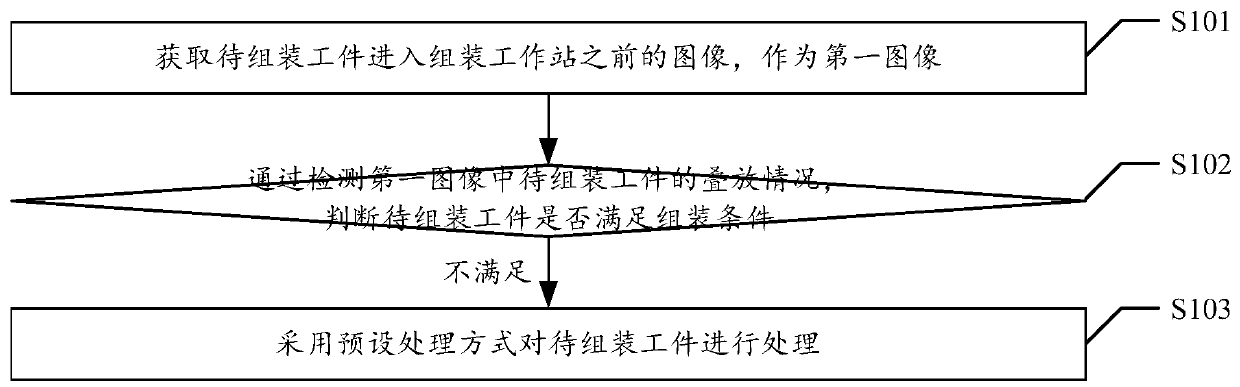

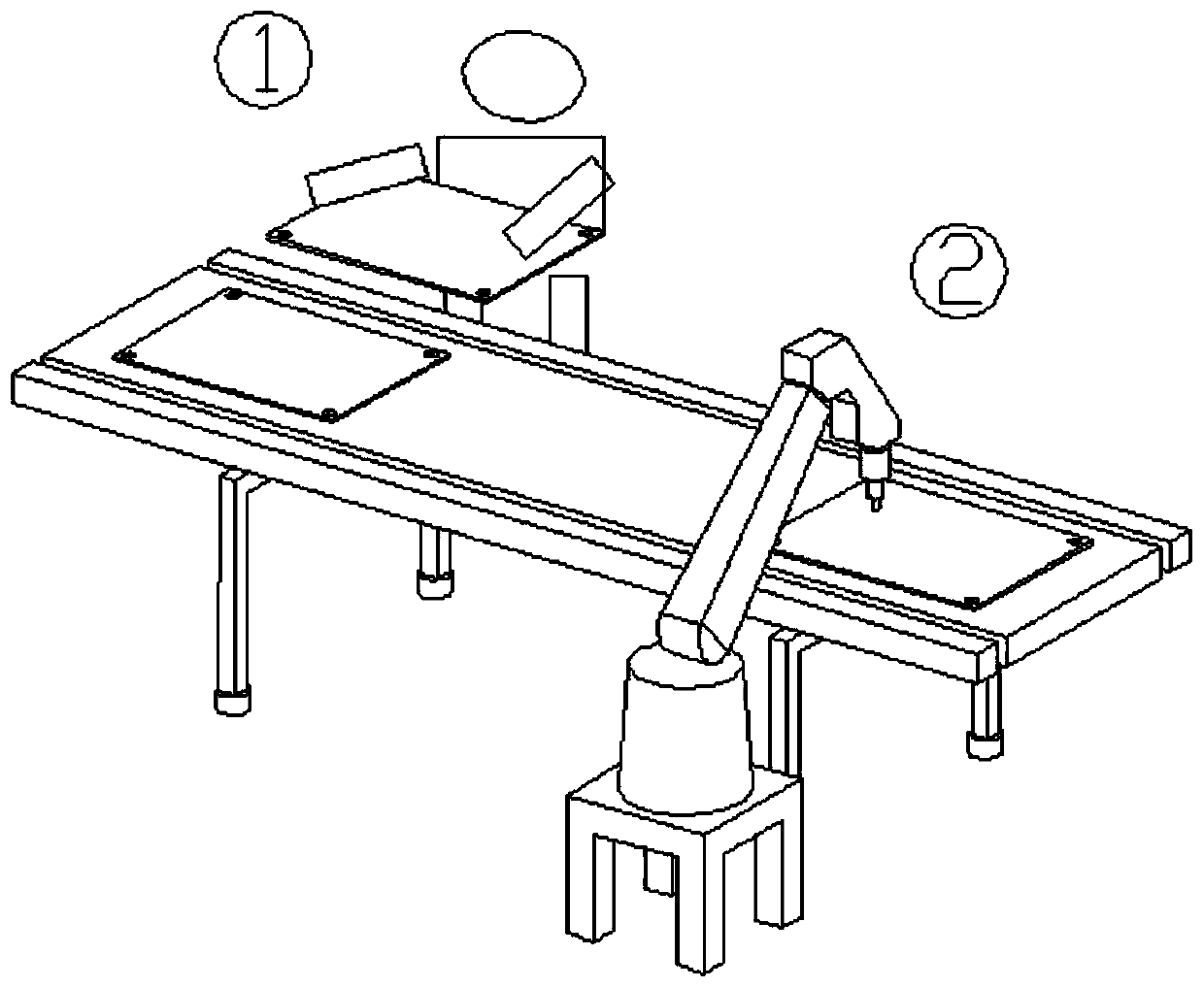

Workpiece detection and assembly method and equipment and storage medium

PendingCN110836637AReduce assembly error rateUsing optical meansMetal working apparatusWorkstationIndustrial engineering

The embodiment of the invention provides a workpiece detection and assembly method and equipment and a storage medium. The method comprises the steps of: acquiring an image of to-be-assembled workpieces before the to-be-assembled workpieces enter an assembly workstation, and using the image as a first image; by detecting a stacking situation of the to-be-assembled workpieces in the first image, judging whether the to-be-assembled workpieces meet assembly conditions; and if no, processing the to-be-assembled workpieces in a preset processing mode. Therefore, in the scheme, before the workpiecesenter the assembly workstation, the workpieces which do not meet the assembly conditions can be detected out and be processed, so that only the workpieces which meet the assembly conditions are assembled, thereby reducing an assembly error rate.

Owner:BOE TECH GRP CO LTD

Method for assembling components of printed circuit board

InactiveCN107613667AImprove assembly efficiencyAssembly is slowPrinted circuit assemblingPrinted circuit board

The present invention relates to a method for assembling components of a printed circuit board. The method has the advantages that the assembly efficiency is improved, the time required for searchingfor the components is significantly reduced, the assembly period is short and at least a half of an assembly time is saved, phenomena of wrong assembly and missed assembly are reduced, and the reworkrate is reduced.

Owner:SHAANXI QIANSHAN AVIONICS

An intelligent conveying software and hardware integrated assembly system and process

ActiveCN109143957BIntegrated intelligenceImprove reliabilityProgramme control in sequence/logic controllersComputer hardwareComputer architecture

The invention provides an intelligent transportation software and hardware integrated assembly system and process, including: a custom header file module, a data structure list export module, a CAD drawing reading module, a CAD data file export module, a data comparison module, and a CAD drawing definition Modification module, automatic programming module; the correspondence also includes the step of exporting the data structure list in the custom header file, the step of reading the CAD drawing, the step of exporting the CAD data document, the step of comparing the data structure list and the CAD data document, and according to the comparison result, Call the custom header file to perform automatic programming steps; the intelligent transportation software and hardware integrated assembly system and process of the present invention realize intelligent and automatic logistics machine hardware assembly and software integration, and reduce the error rate of hardware assembly at the same time, especially in In the development and application of intelligent workshops, the development time is greatly reduced through the system and process of the present invention, the efficiency of software and hardware integrated assembly is improved, and the intelligent transportation and distribution of logistics in the workshop are realized.

Owner:KUNSHAN TUNGRAY IND AUTOMATION

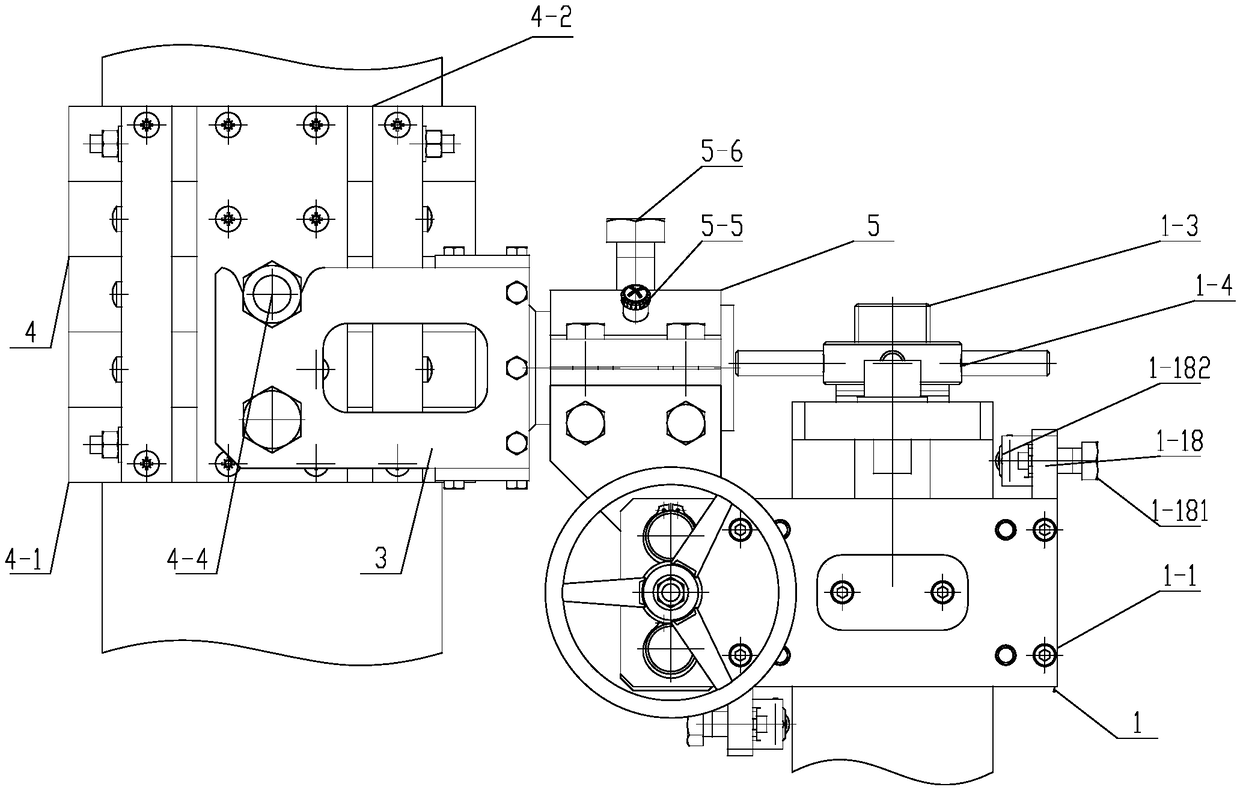

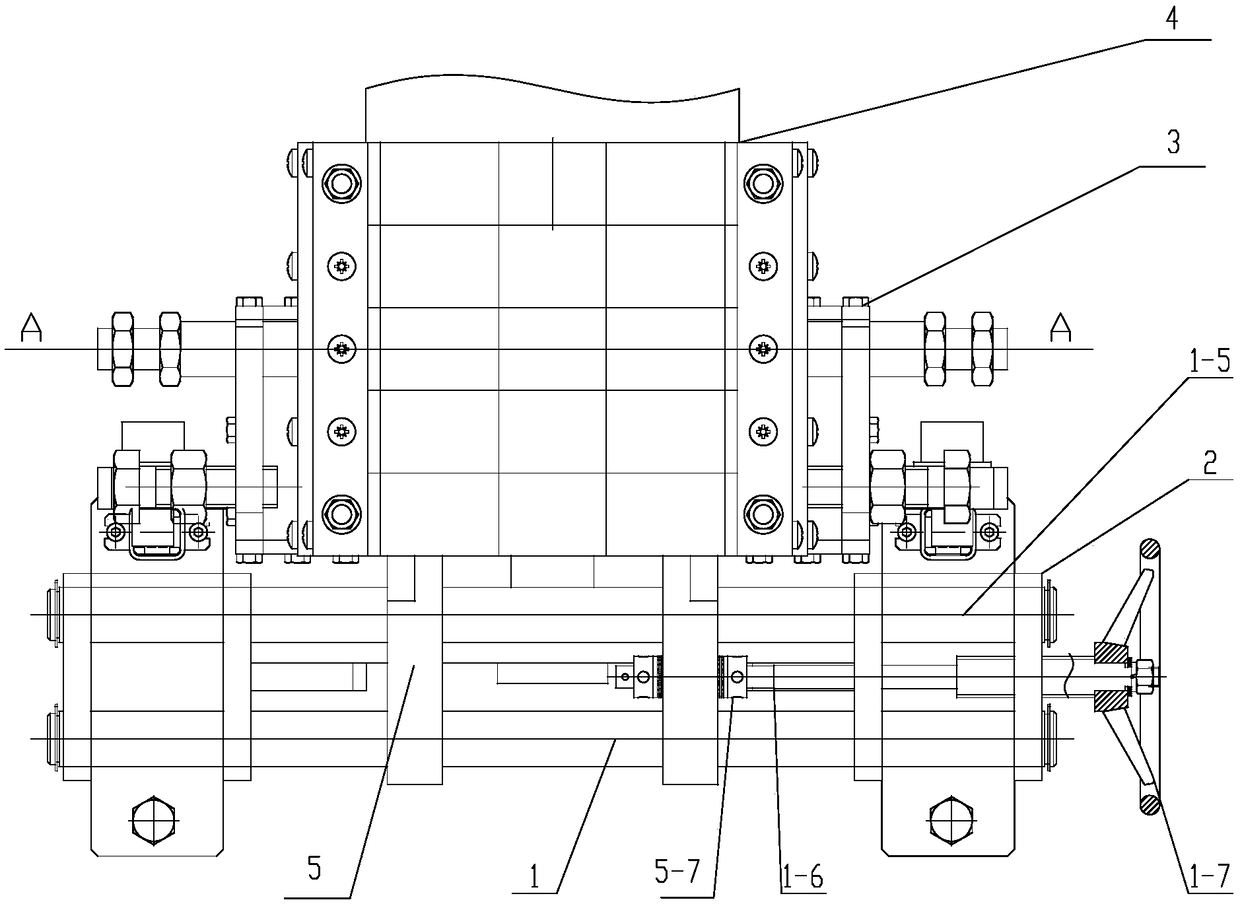

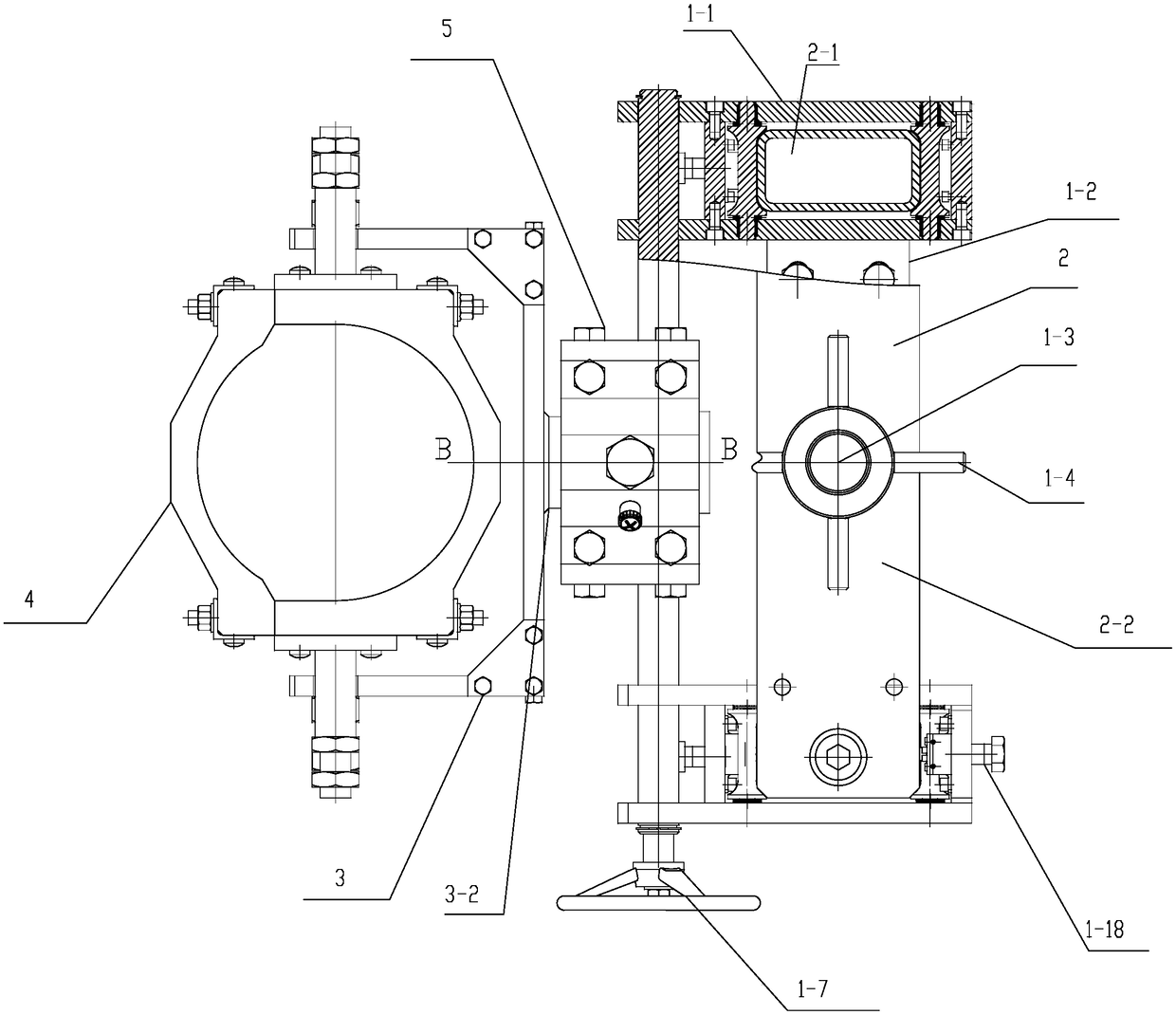

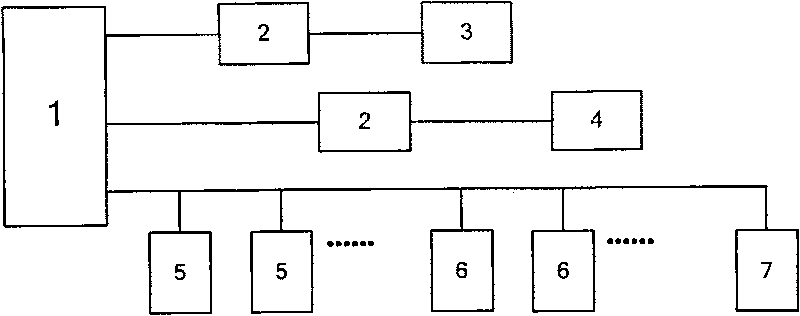

Large Size Platinum or Platinum-Rhodium Crucible Holder Assemblies

ActiveCN106826067BReduce welding errorsReduce assembly error rateWelding/cutting auxillary devicesAuxillary welding devicesPlatinumEngineering

The invention relates to a clamping assembly for a large-size platinum or platinum-rhodium crucible and belongs to the technical field of machinery. The clamping assembly comprises a vertical moving mechanism, a locating mechanism, a crucible bracket, a clamping component and a crucible supporting component, wherein the vertical moving mechanism is connected with the locating mechanism; the clamping component is connected with the crucible bracket, the crucible bracket is connected with the crucible supporting component, and the crucible supporting component is connected with the vertical moving mechanism. According to the clamping assembly, through adjusting angles of a plurality of directions of the crucible, the crucible for melting substrate glass can be in strict angle control, welding errors are reduced greatly, and the error rate of assembling is lowered. The clamping assembly is simple and convenient in operation and is applicable to large-scale application and popularization.

Owner:英特派铂业股份有限公司

Mixed flow assembly line intelligent material gallow device possessing visualized monitoring function

InactiveCN101308367BInstructions are accurateReduce assembly error rateProgramme controlComputer controlManufacturing cost reductionVisual technology

The invention belongs to the mixed-model assembly line material management and assembly monitoring technology, relating to a mixed-model assembly line smart rack device with visual monitoring function. The device is composed of a single chip, a bus interface, a RFID reader, an assembly display screen, indicator lights, assembly buttons and buzzers; wherein, the single chip is connected with a plurality of indicator lights, assembly buttons and a buzzer. The RFID reader and the assembly display screen are respectively connected with the single chip through the bus interface to form a serial communication mode with the single chip. The invention uses the data acquisition real-time and visual technology to manage and monitor the mixed-model assembly process and can reduce the error rate in engine assembly, improve product quality and work efficiency, as well as reduce manufacturing costs.

Owner:HUAZHONG UNIV OF SCI & TECH

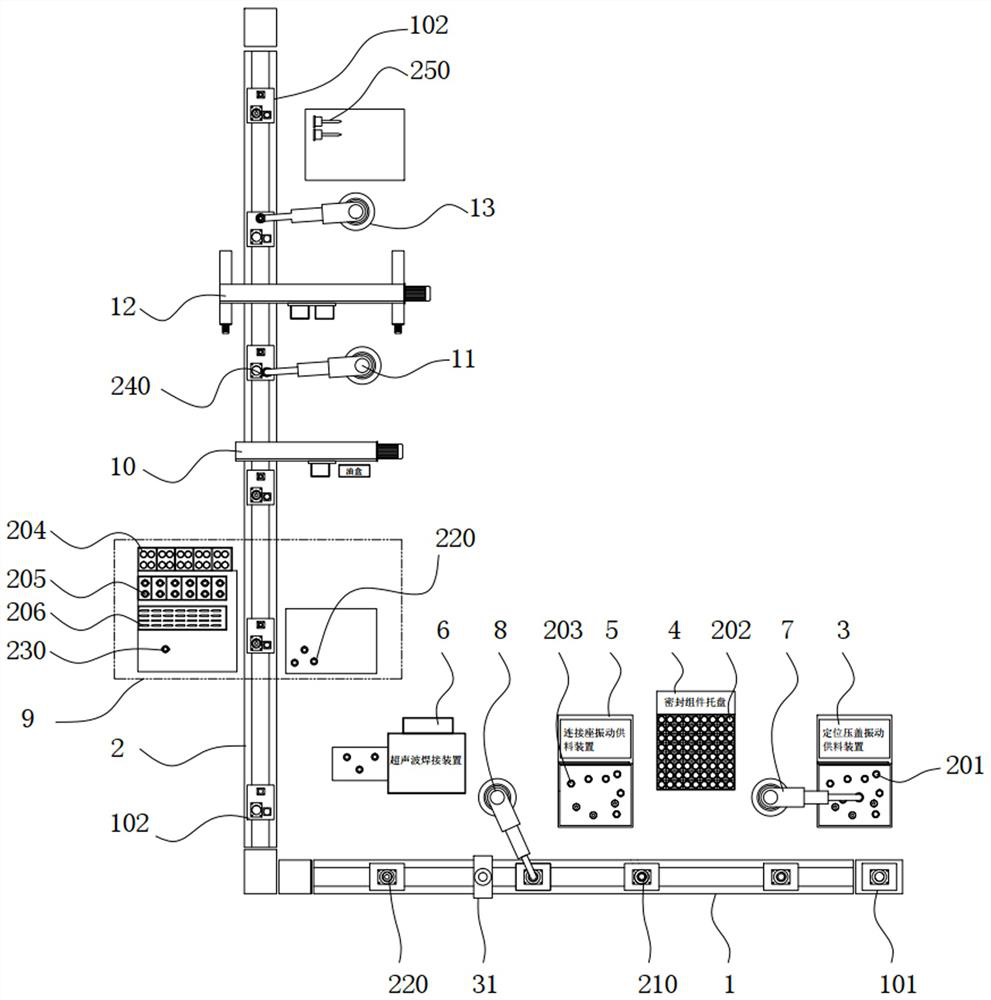

Puncture outfit assembly line

PendingCN114102131ARealize automatic assemblyImprove assembly efficiencyCannulasSurgical needlesUltrasonic weldingEngineering

The invention discloses a puncture outfit assembly line, and belongs to the technical field of medical instrument production. The device comprises a first conveying mechanism with a set of auxiliary carriers and a second conveying mechanism with a set of main carriers, and a positioning gland vibration feeding device, a sealing assembly feeding tray, a connecting base vibration feeding device and an ultrasonic welding device are sequentially arranged on one side of the first conveying mechanism in the running direction. A first mechanical arm is arranged between the positioning gland vibration feeding device and the sealing assembly feeding tray, a second mechanical arm is arranged between the connecting base vibration feeding device and the ultrasonic welding device, and a manual assembly station is arranged at the process front end of the second conveying mechanism. A sealing gasket oiling device, a third manipulator with a screwing function and a sleeve gluing and assembling device are sequentially arranged on one side of the second conveying mechanism, and a fourth manipulator is arranged at the process tail end of the second conveying mechanism. The puncture outfit assembly line is high in assembly efficiency and good in qualified rate.

Owner:ANHUI AOFO MEDICAL EQUIP TECH

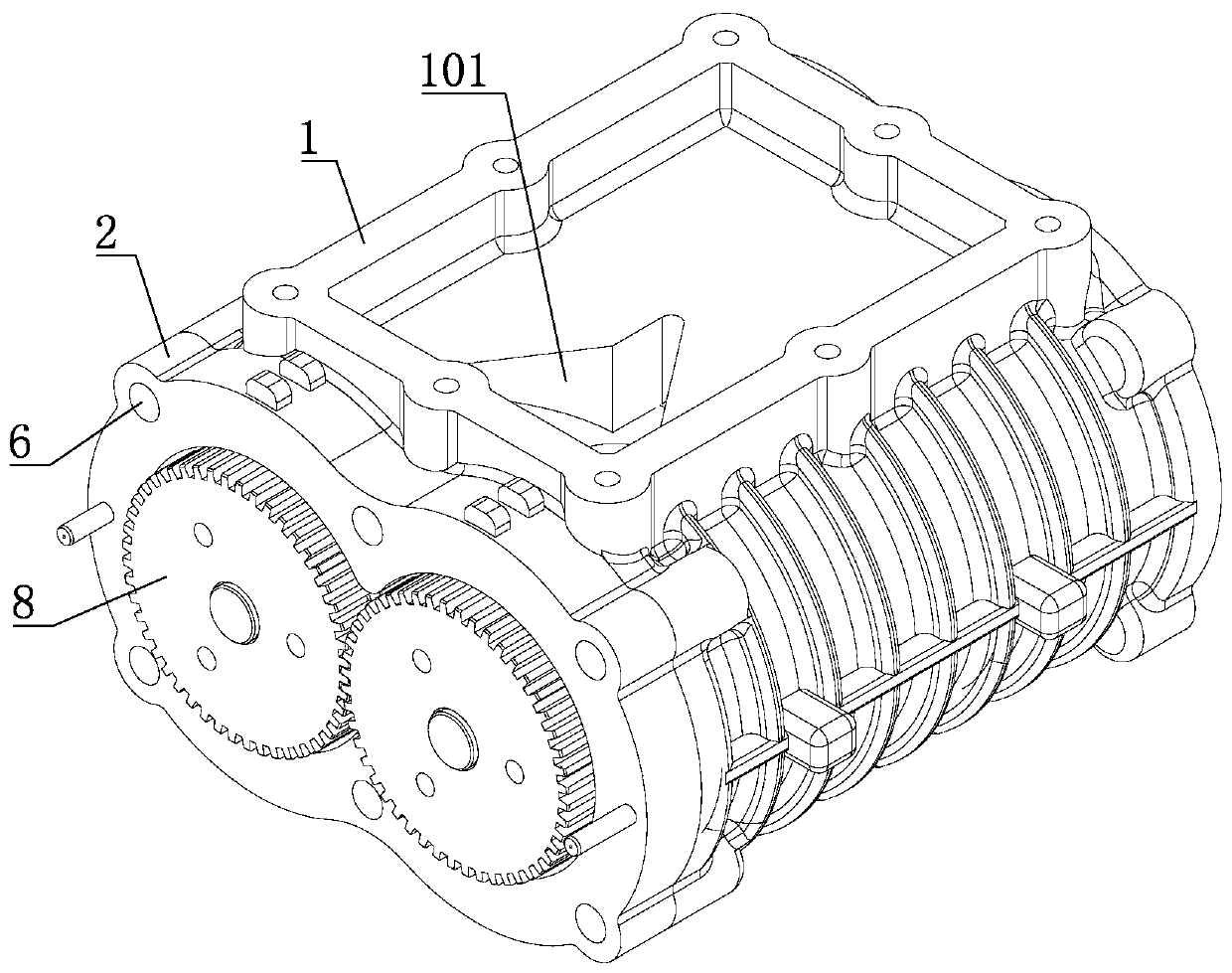

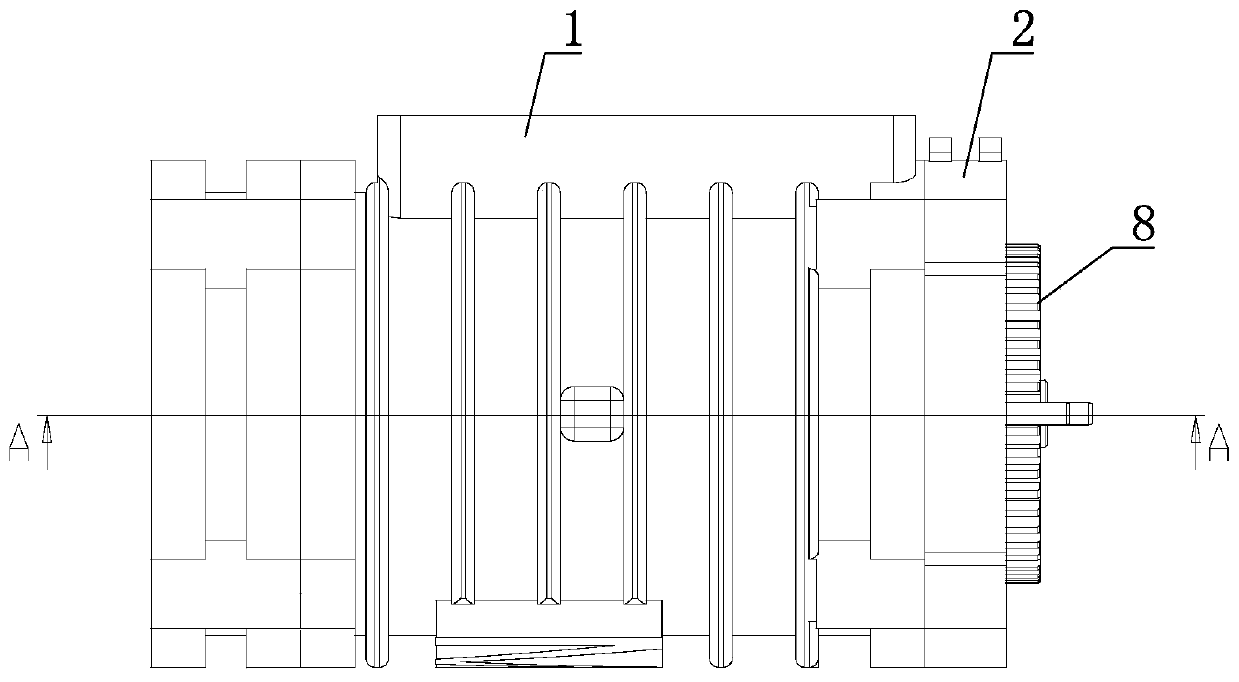

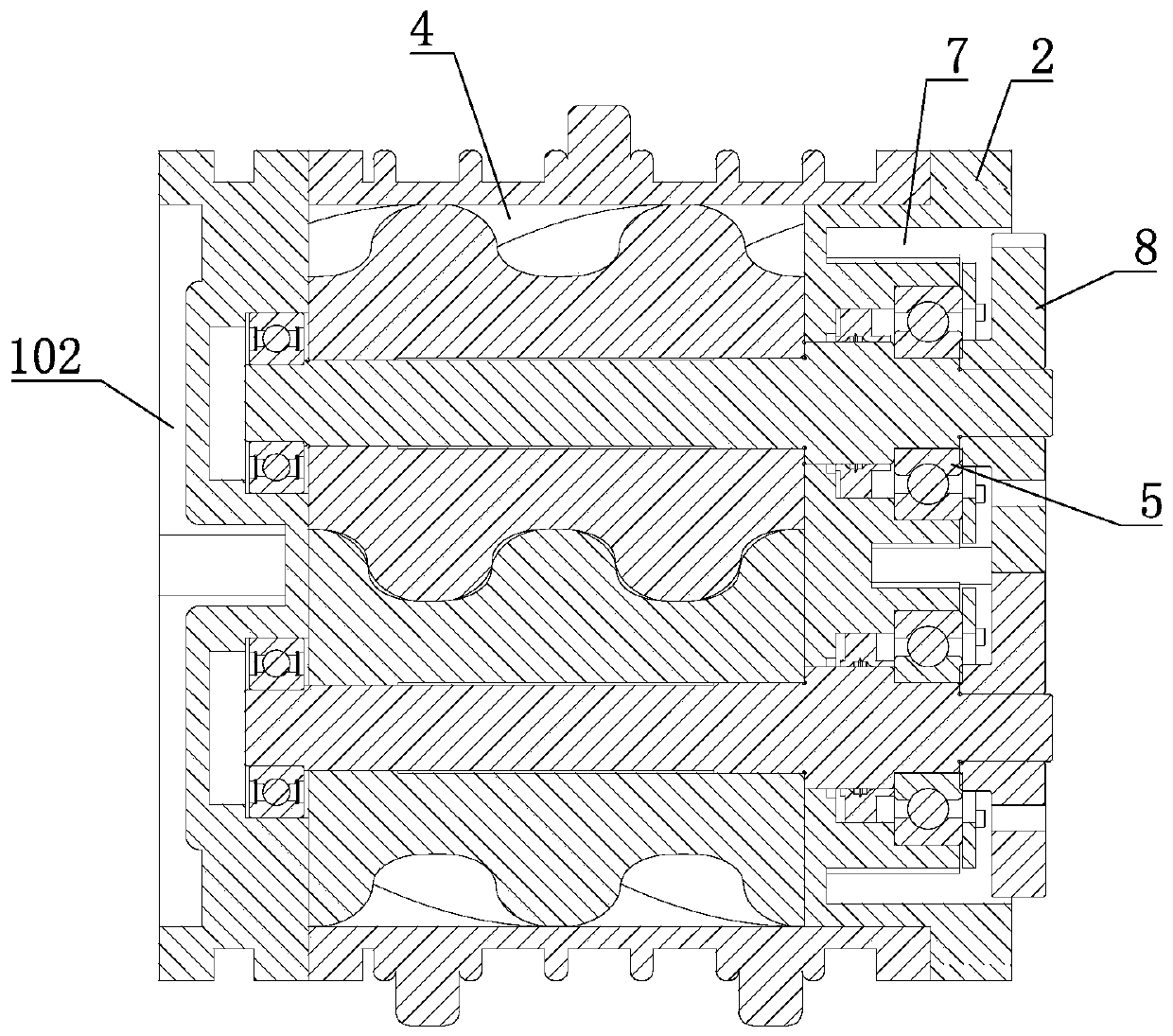

Six-blade roots supercharger

PendingCN109944798AReasonable structural designImprove work efficiencyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsMachiningElectrical and Electronics engineering

The invention relates a six-blade roots supercharger comprising a casing, a first end cover and a second end cover. The casing is internally provided with an air chamber for installing a rotor, and the two ends of a rotating shaft of the rotor in the air chamber are each provided with a bearing; an air outlet is formed in the exhaust position, corresponding to the rotor, of the casing, and an airinlet is formed in the intake position, corresponding to the rotor, of the casing; the first end cover is arranged on the side, close to the air outlet, of the casing, and connected with the end of the casing detachably; the first end cover and the casing are provided with connecting holes which are formed coaxially; and the second end cover is provided with a plurality of connecting holes coaxially formed with the first end cover, and connecting pieces are arranged in the connecting holes, coaxially arranged, of the first end cover, the second end cover and the casing. The six-blade roots supercharger is rational in structural design, and a plurality of coaxial connecting holes are formed among the supercharger casing, bearing end covers and a motor end cover, and the three parts are connected through the connecting pieces synchronously; the drilling and assembly procedures are reduced, and equivalently the assembly error rate is reduced; and the machining and assembly efficiency is improved, and the structural strength is ensured.

Owner:烟台东德氢能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com