Chain saw guide plate structure

A technology of chainsaw guide plate and guide plate, which is applied in the direction of chain saws, sawing equipment, working accessories, etc. It can solve the problems of the guide wheel being stuck in rotation, the outer diameter cannot be changed, and the assembly is inconvenient, so as to reduce material damage and assembly errors. efficiency and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

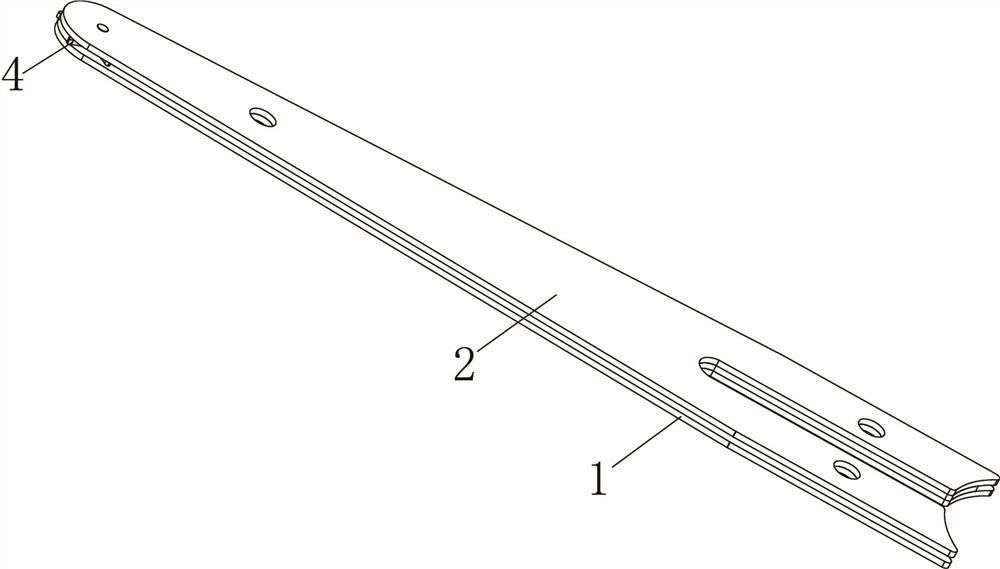

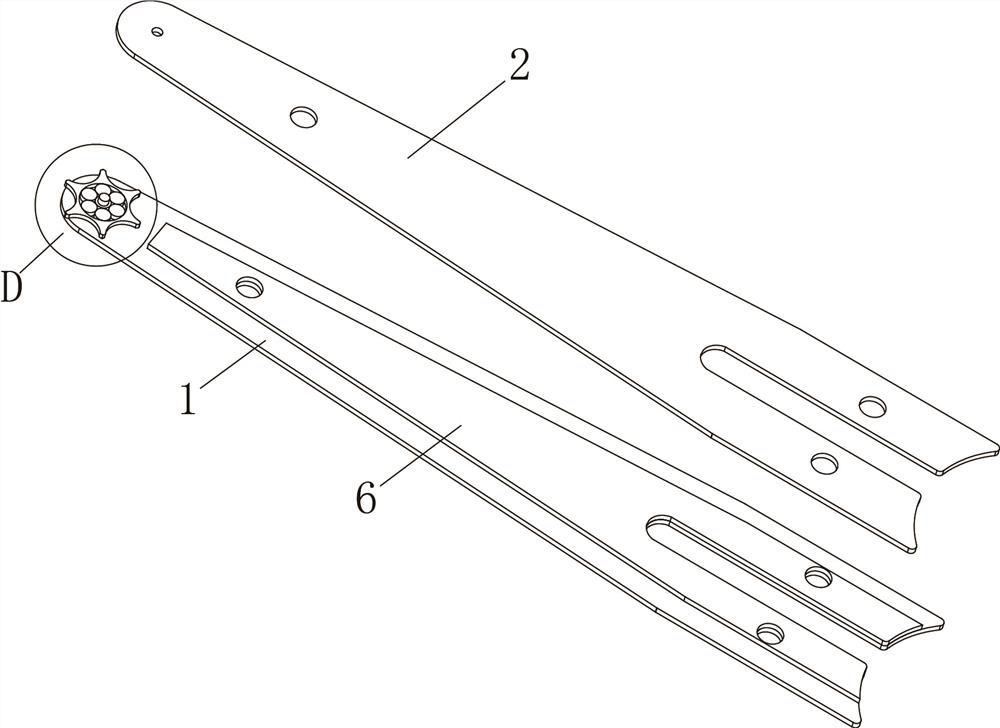

[0030] see Figure 1-Figure 5 , Chainsaw guide plate structure, including the first guide plate 1, the second guide plate 2, the connecting shaft 3, the guide wheel 4 and a number of rolling elements 5.

[0031] The first guide plate 1 and / or the second guide plate 2 includes or is provided with an intermediate guide plate 6, the first guide plate 1 and the second guide plate 2 clamp the intermediate guide plate 6 inside, and the three cooperate to form a saw chain for fitting The guide plate groove, this structure is the same as in the prior art.

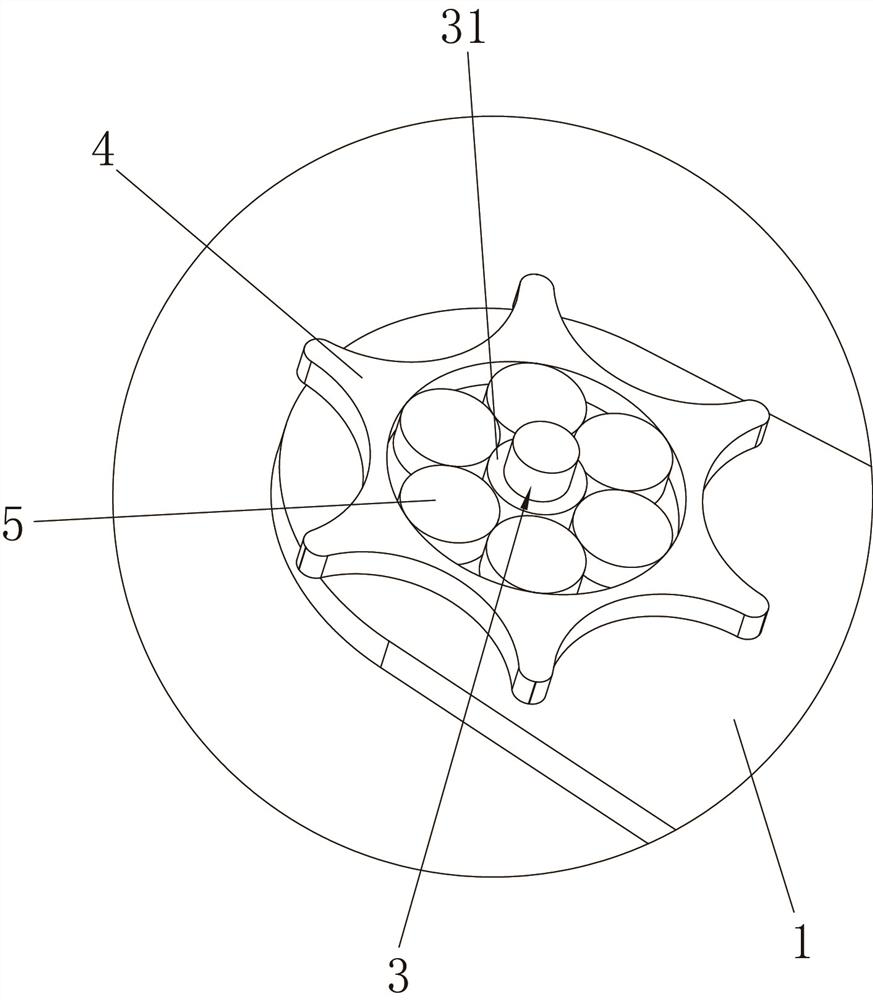

[0032] The connecting shaft 3, the rolling element 5 and the guide wheel 4 are arranged at the same end positions of the first guide plate 1 and the second guide plate 2, specifically, as figure 2 and image 3 Shown:

[0033] The guide wheel 4 includes a number of protruding teeth that match the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com