Novel ball screw rod device

A ball screw, a new type of technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of scars on the contact surface between the screw and the nut, inconvenient oiling and lubrication of parts, and narrowing of the internal moving space to achieve lubrication. The effect is good, the processing surface of the slide seat is reduced, and the assembly time is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

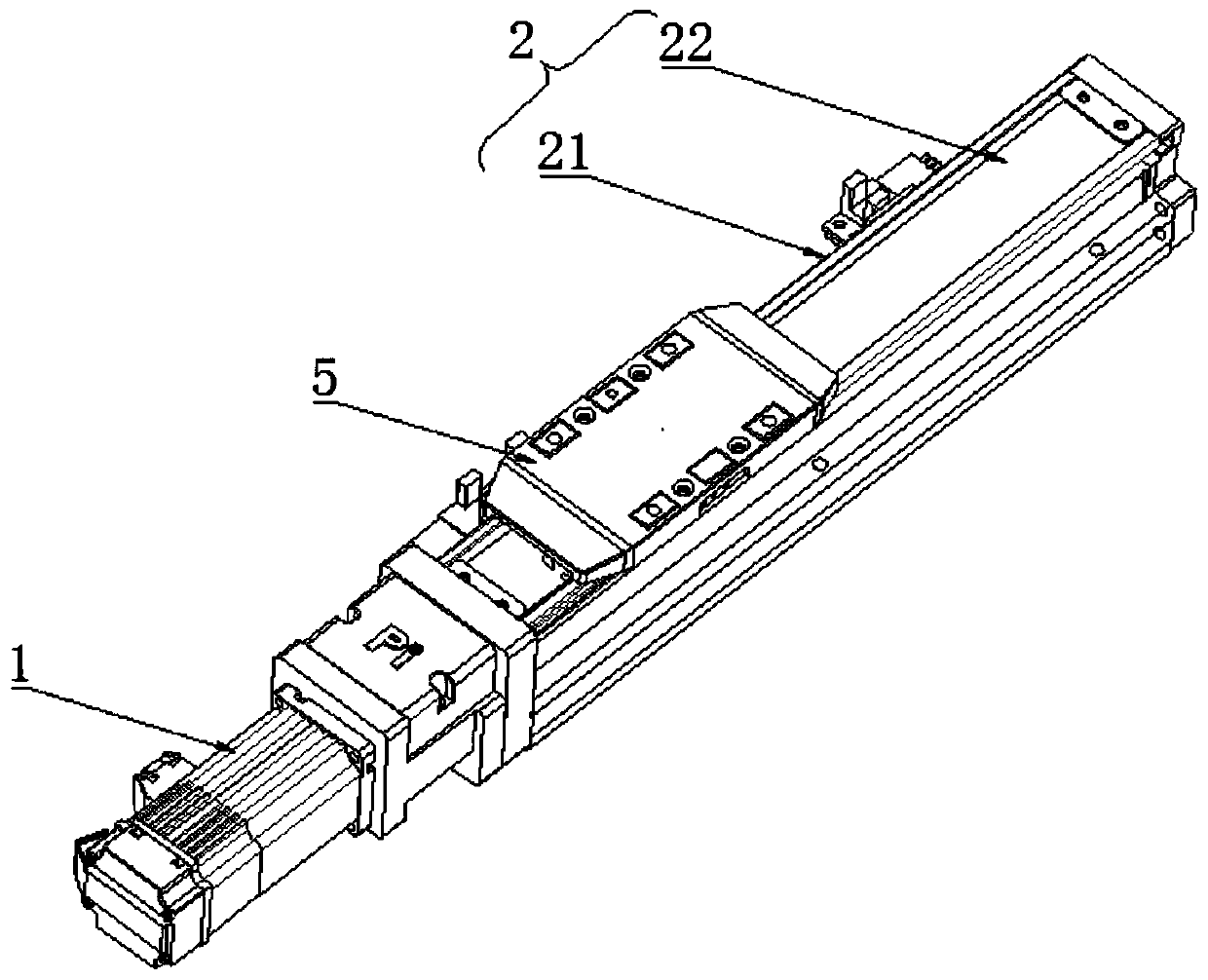

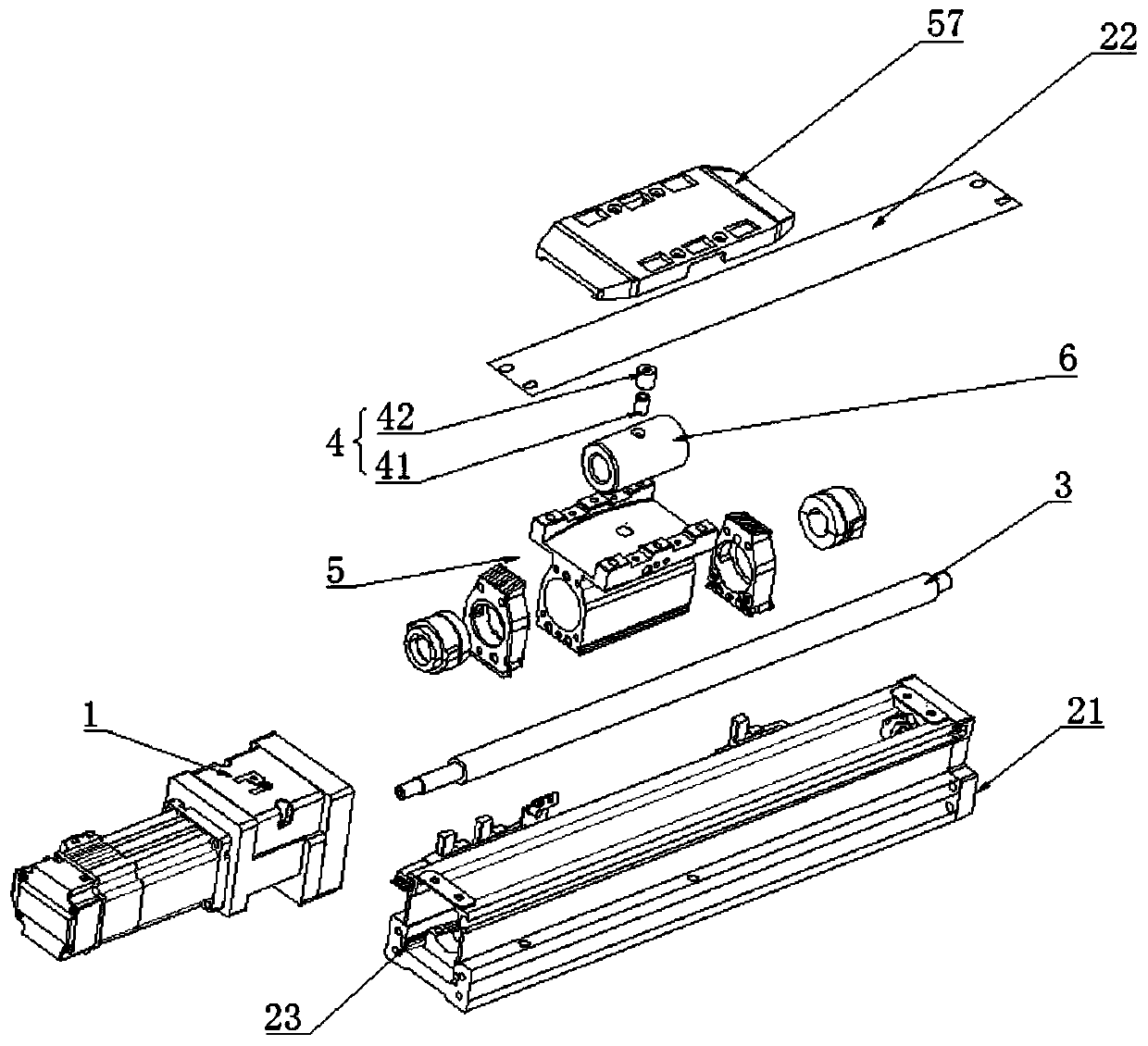

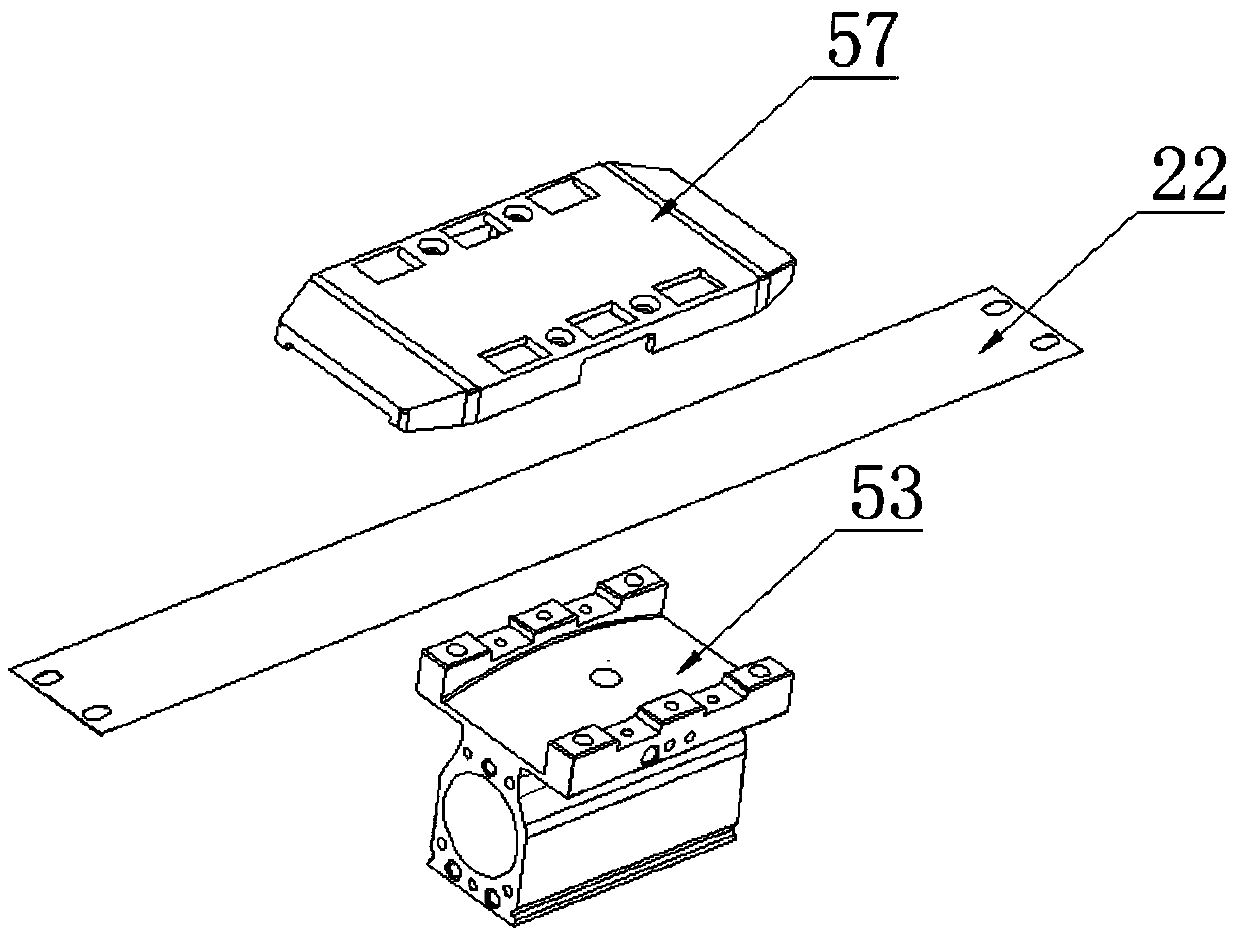

[0061] refer to Figures 1 to 9 As shown, the present invention provides a new type of ball screw device, including a motor 1, a screw 3, a nut 6, a slide 5, and a pin assembly 4; the middle of the slide 5 is provided with a mounting hole, and the nut 6 is coaxial Embedded in the installation hole; the screw rod 3 passes through the installation hole and is screwed with the nut 6; the top of the slide seat 5 is provided with a first through hole 52, and the position corresponding to the first through hole 52 on the side of the nut 6 A pin hole 321 is provided; the pin assembly 4 is used to fixedly connect the nut 6 with the sliding seat 5 through the first through hole 52 and the pin hole 321; the sliding seat 5 is also provided with several oil storage tanks, several flow channels, and several The flow channel is used to communicate with seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com