Mixed flow assembly line intelligent material gallow device possessing visualized monitoring function

An assembly line and mixed-flow technology, which is applied in the direction of cooperative operation devices, program control, computer control, etc., can solve the problem that there is no combination of material data collection and material assembly, and the inability to realize error-proof loading, missing loading, and material synchronous distribution control Integration with visual monitoring and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

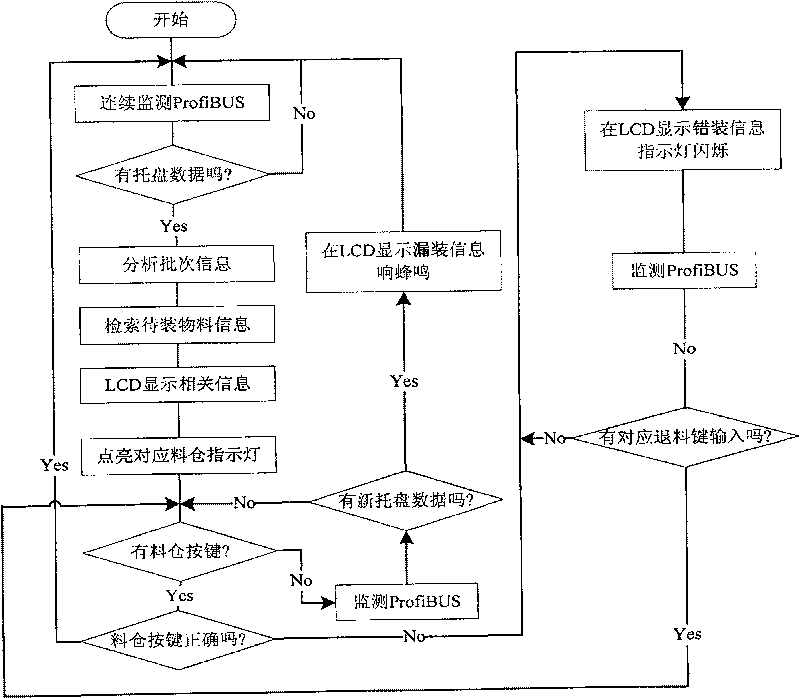

[0022] This embodiment is the LB140.2 process of the engine long hair assembly line of an engine manufacturing company in China. This process requires 11 different types of engines: 1.8FC cast iron engine assembly (for 481FC UMC T11), 1.8FC cast iron engine assembly Cheng_(for 481FC UMC B11), 1.8FC cast iron engine assembly_(for 481FC UMC A21), 1.6FD cast iron engine assembly_(for 481FD UMC A21), 1.6LC engine assembly (for 481F UMC export), 1.6LC Engine assembly (481F UMC T11), 2.0NALC engine assembly_T11, 2.0NALC engine assembly_B11, 2.0NALC engine assembly_A21, 1.6LCBR engine assembly_A21, 1.6LLC engine assembly For A21 use. Respectively install those that meet the requirements of the respective engine models: intake pipe gasket, wire harness bracket, exhaust pipe. These parts are stored in the material bin of the material rack, and are taken out from the material bin by the assembler during installation.

[0023] For example: when the pallet carrying the 1.8FC cast iron e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com