Conveyor unit for a fuel cell system for conveying and/or controlling a gaseous medium

A fuel cell system and gaseous medium technology, applied in the direction of fuel cells, power system fuel cells, electrical components, etc., can solve the problems of reducing the efficiency of the fuel cell system of the conveying unit, and achieve the effect of improving the effect of the injection pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

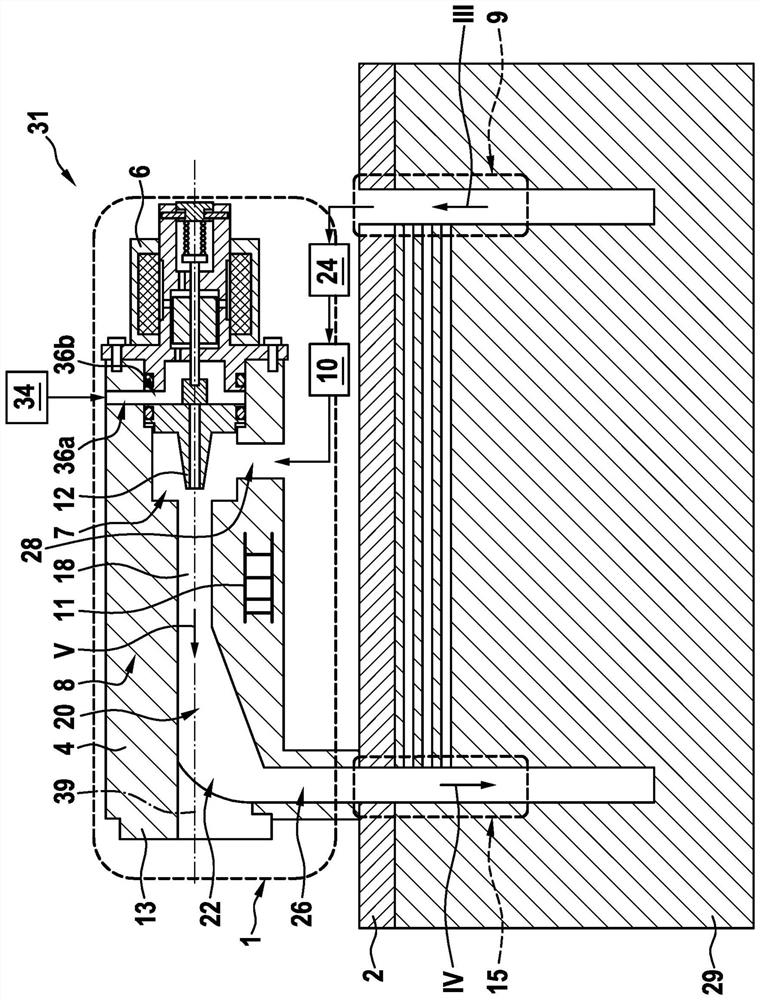

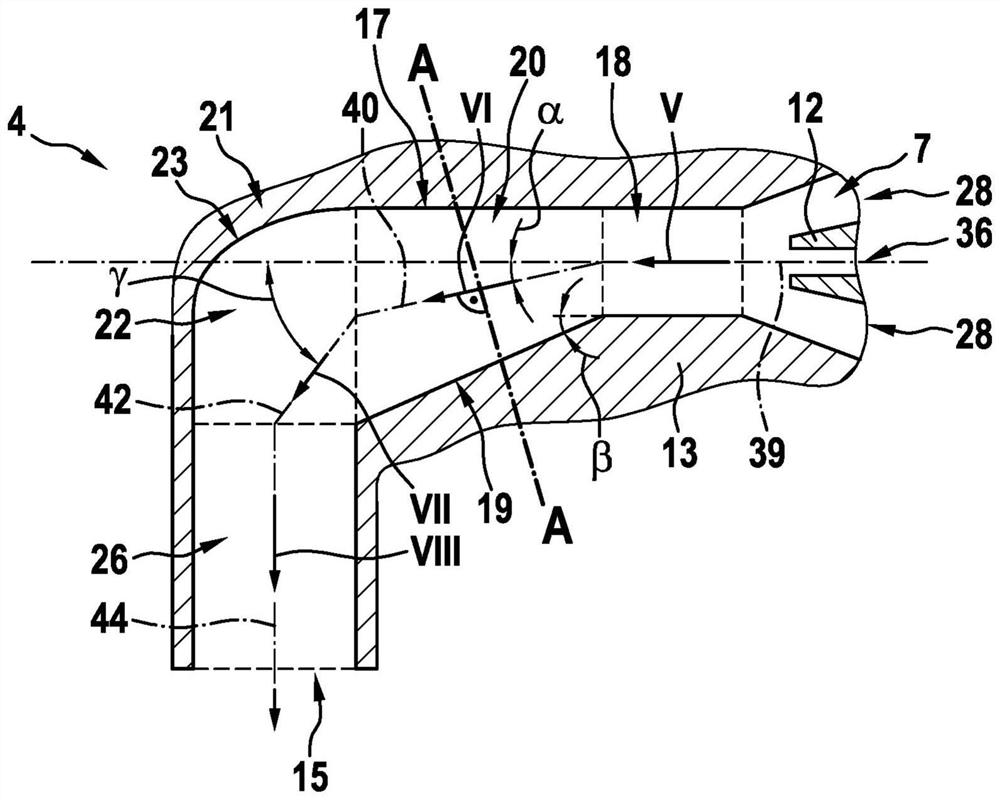

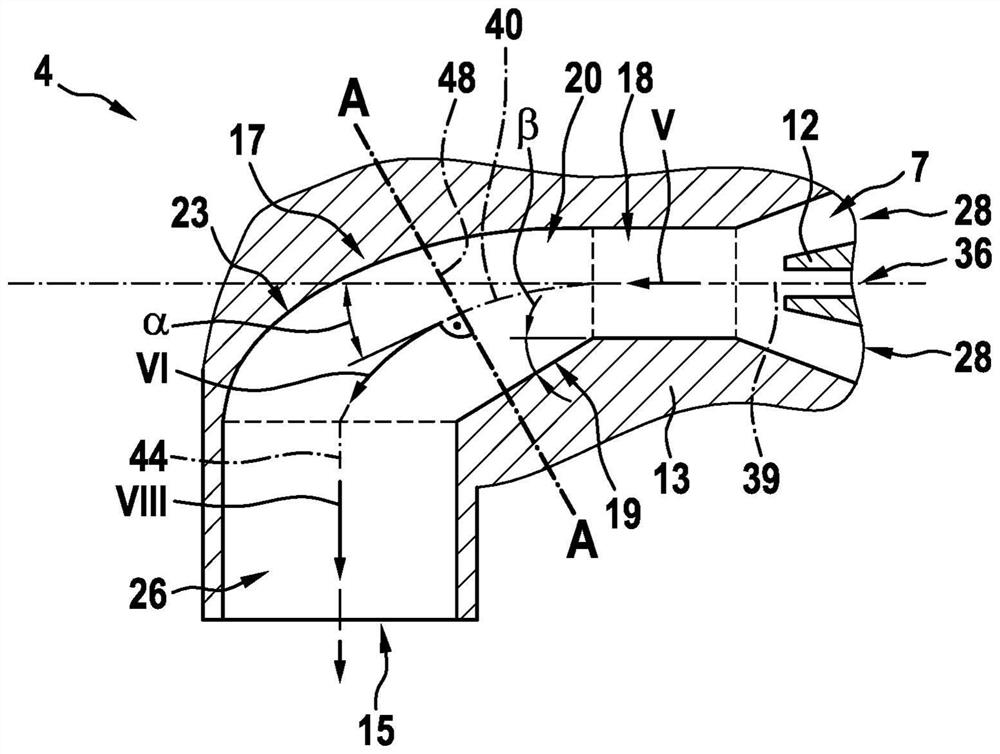

[0025] according to figure 1 The illustration in FIG. 2 shows a schematic sectional view of a fuel cell system 31 with a delivery unit 1 , wherein the delivery unit 1 has a combined valve-injection pump assembly 8 . The combined valve-jet pump assembly 8 here has a metering valve 6 and a jet pump 4 , wherein the metering valve 6 is connected to the jet pump 4 , in particular to the base body 13 of the jet pump 4 , for example by means of a threaded connection.

[0026] The jet pump 4 has here in its base body 13 a first inlet 28 , a second inlet 36 a , a suction region 7 , a mixing tube 18 , a diffuser 20 as well as an outlet elbow 22 and / or a connecting piece 26 . The metering valve 6 has a second inlet 36 b and a nozzle 12 . In this case, the metering valve 6 is inserted in particular in the direction of the first longitudinal axis 39 of the mixing tube 18 into an opening in the injection pump 4 , in particular in the base body 13 of the injection pump 4 .

[0027] exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com