Intelligent conveying software and hardware integrated assembling system and technology

A technology of intelligent transportation, software and hardware, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of low efficiency of manual reading of drawings, longer complete cycle, error-prone, etc., to achieve intelligent transportation and decentralization, The effect of reducing development time and error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be clearly and completely described below.

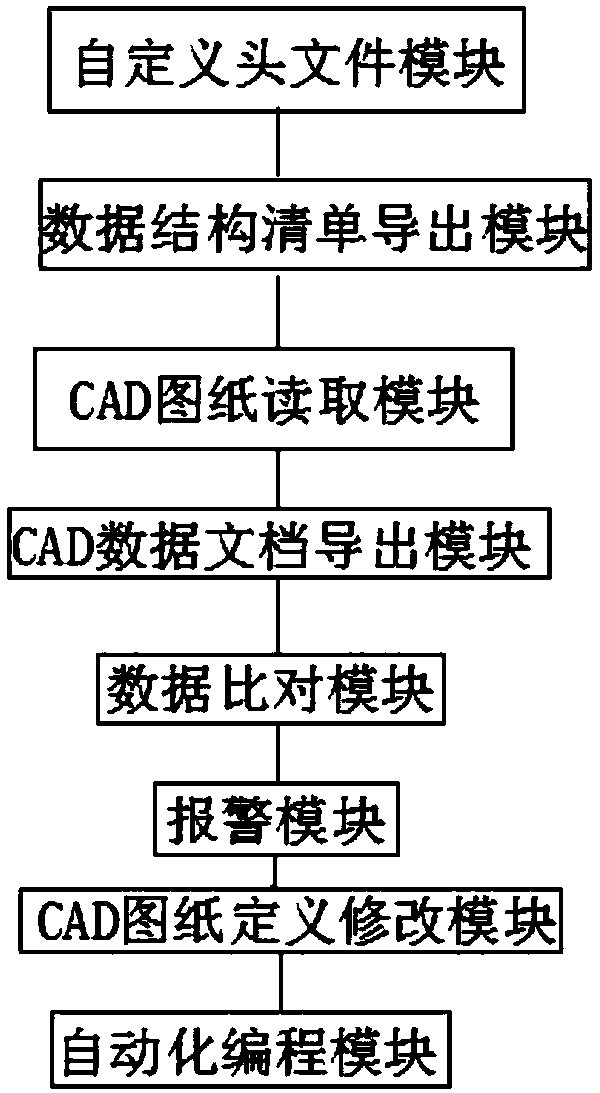

[0051] Such as figure 2 As shown, an intelligent conveying software and hardware integrated assembly system includes:

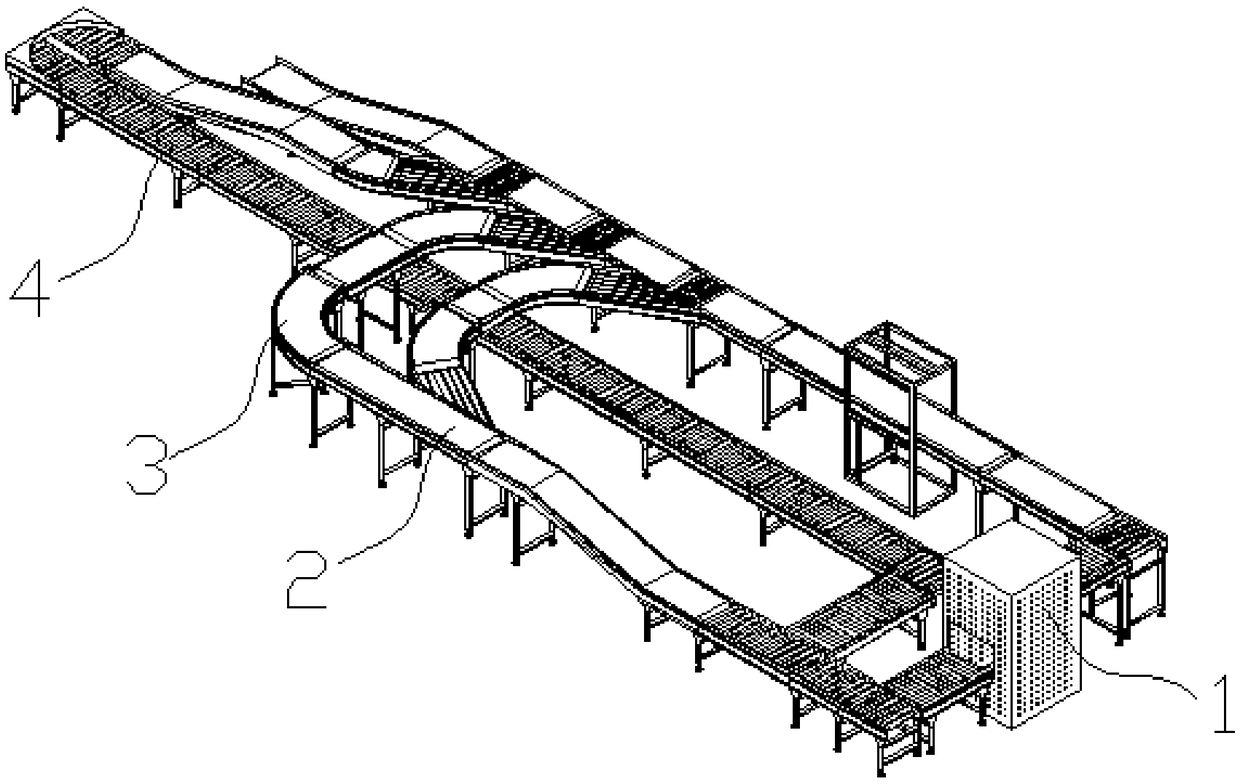

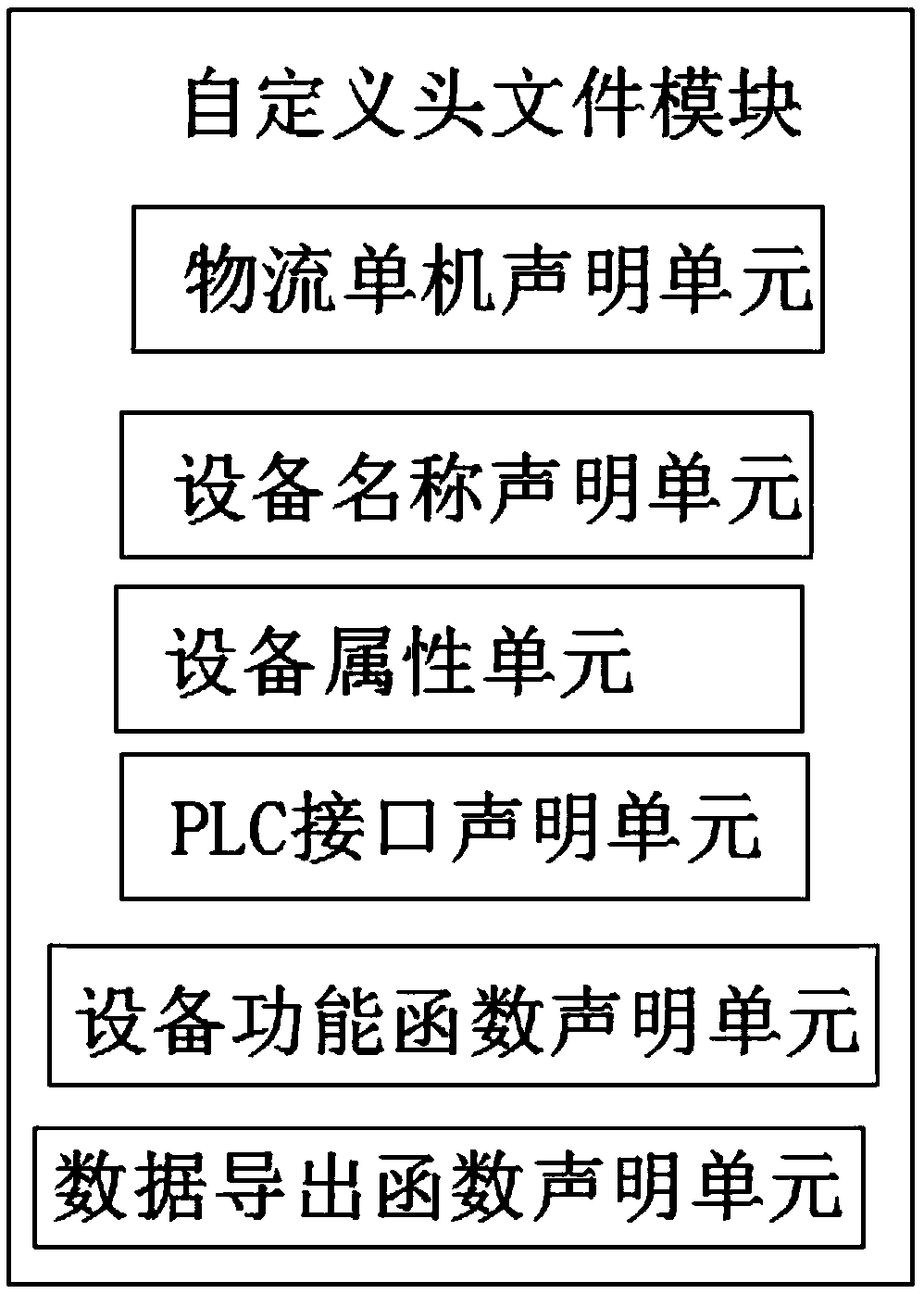

[0052] Custom header file modules such as image 3 As shown, it includes a logistics stand-alone declaration unit, a device name declaration unit, a PLC interface declaration unit, and a device function declaration unit. , PLC interface, and equipment function functions are defined and declared; it should be noted that the logistics machine is composed of a hoist 1, a belt conveyor 2, a turning machine 3, a roller conveyor 4 and other logistics stand-alone machines. For block design and naming, each logistics stand-alone machine is composed of basic equipment such as sensors, pneumatic motors, and motors, and is controlled by PLC. This is a conventional technical means in the field, and will not be repeated here.

[0053] The intelligent transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com