AR fastener auxiliary assembly system and method based on projection display

An auxiliary assembly and projection display technology, applied in the AR field, can solve the problems of unsuitable fasteners for batch assembly guidance, lack of detection feedback links, discontinuous assembly process, etc., so as to improve the efficiency of manual assembly and reduce the level of cognition and experience. Judgmental requirements, effects of increasing the level of continuity and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Aiming at large quantities, multiple types, and confusing fastener assembly scenarios, the present invention provides an augmented reality-based fastener auxiliary assembly system, which projects the abstract assembly guidance process on the assembly operation site in an AR visualization manner, and Provide real-time detection and feedback on assembly results, reduce the cognitive burden of operators, improve assembly efficiency, and reduce assembly error rates.

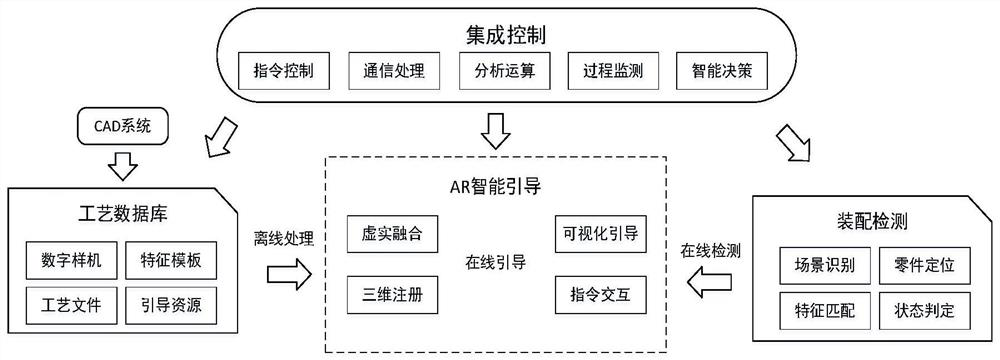

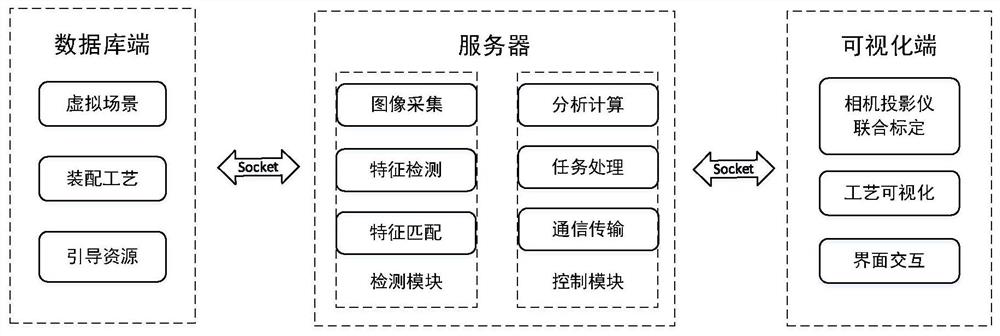

[0034] Such as figure 1 As shown, an AR fastener auxiliary assembly system based on projection display, including a process database module, an AR intelligent guidance module, an assembly detection module and an integrated control module;

[0035] The process database module includes a computer, a process database and a CAD system, is responsible for storing and managing assembly proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com